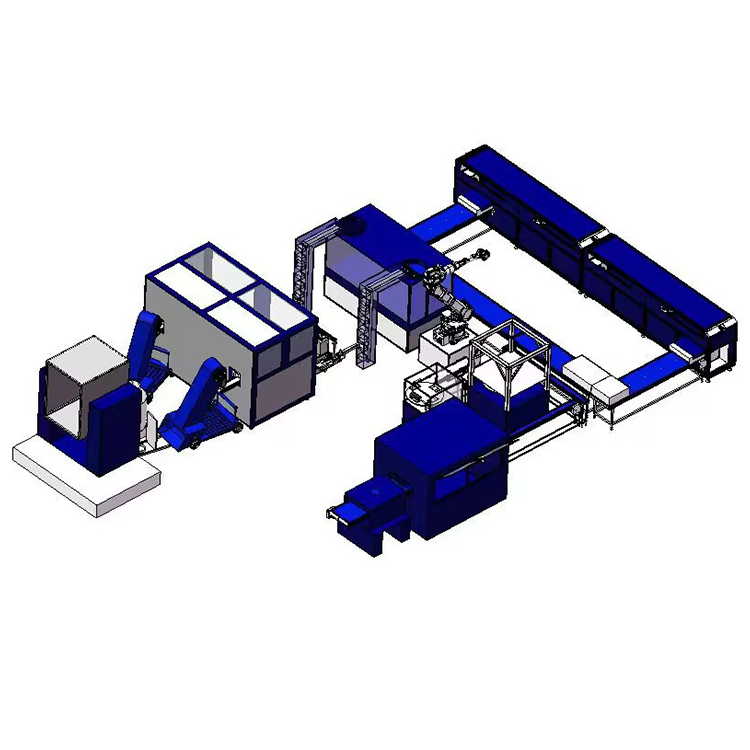

Tunnel Type Gold Ingot Vacuum Casting System

A Logical Solution

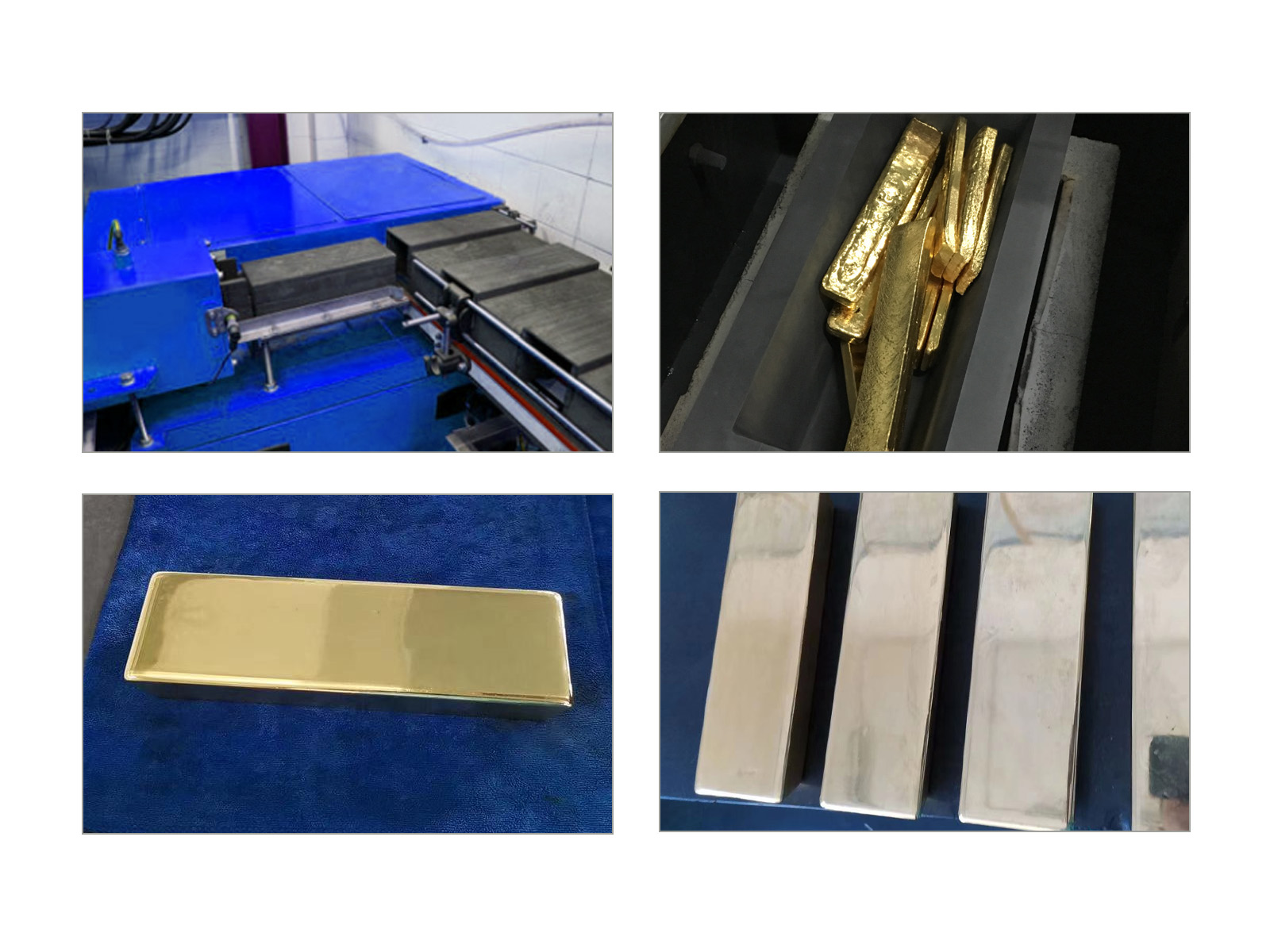

In the past years, the market of investment precious metals has become more and more demanding: nowadays an ingot must have the same aesthetic properties of a jewel.

Using the machines available on the market prior to the launch of HS-VF260, one could manufacture products of reasonable quality, but it was difficult for operators to manage them. As a matter of fact, calibration of work parameters and ordinary maintenance were almost exclusively limited to highly-specialized staff.

The launch of HS-VF260 revolutionized the field: companies all over the world were supplied with tailored tunnel furnaces, scalable according to production types (ingot from 1 ounce, up to 400 ounces or 1000 ounces), whose maintenance was accessible.

The only solution was designing an induction tunnel furnace with an easy and user-friendly interface (HMI touch screen), that could be even completely disassembled with just one wrench.

Critical Issues And Disadvantages Of The Traditional System

The furnace is in the open air and the flame is always burning, hence risks of accidents at work are very high.

Higher risks of metal loss.

Significant emission of fumes, whose recovery is very expensive for the company, and development of a strong electromagnetic field.

A lot of consumables, such as crucibles, are used and worn out quickly, implying high operating costs.

The quality of the finished ingot (shininess, purity, flatness) is medium-high.

The furnace requires the constant presence of operators.

Tunnel Furnace Gold Vacuum Casting System

productivity: 4 blocks/hour, each block weighs 15kg;

Maximum working temperature: 1350-1400 degrees Celsius;

Type of protective gas: nitrogen; Air consumption: 5/H;

Furnace inlet water temperature and generator: up to 21 degrees Celsius;

Total water consumption: 12-13/H;

Required cooling water pressure: 3 to 3,5 bar;

Air flow required for ventilation: 0.1 m/s;

Required air pressure from the furnace: 6 bar;

Report Type and Separator: Graphite 400 oz;

The total area of the furnace installation is 18.2M2, the length is 26500mm, and the width is 2800mm.

The melting tunnel node is controlled by the following areas/worksites:

Designed in stainless steel. Application: To pack gold particles into graphite sheets. Main

components: Electric push-step device displacement.

Input parameter area Use:

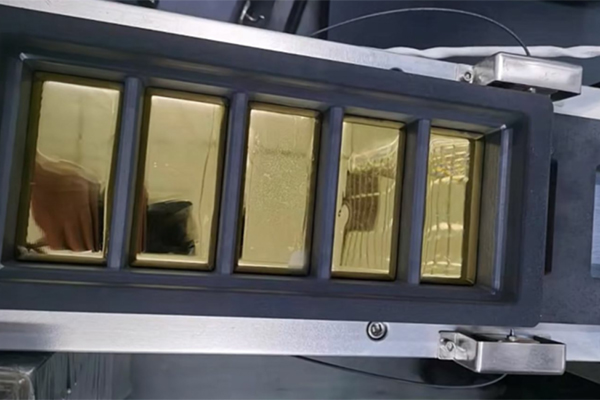

Restrict outdoor air from entering the tunnel Cooling system: water Main components: mobile partition with pneumatic control, nozzle Inject nitrogen.

Melting zone Usage:

used for smelting gold particles Cooling system: water Main components: inductor lined with refractory cement, infrared

Temperature sensor, nitrogen delivery system

Cooling zone:

partition with pneumatic control, nozzle Inject nitrogen. and vacuum.

Unloading zone:

Designed in stainless steel. Purpose:

Extract the finished product from the report.

Power Module, Overall Module: Power supply: 380v, 50Hz; 3 Phases Generator power:

60kW; others are 20KW. Total power required: 80KW

Control Zone:

Workspace for all furnaces

Product Display

What is full automatic tunnel furnace gold bar production line?

Fully automatic tunnel furnace gold bar production line: revolutionizing the gold industry

The gold industry has always been a symbol of wealth and prosperity, and demand for gold bars continues to grow. As technology advances, the production of gold bars has changed dramatically. One of the most innovative developments in the industry is the fully automated tunnel furnace gold bar production line. This cutting-edge technology has revolutionized the way gold bars are manufactured, improving efficiency, precision and quality. In this article, we will explore what a fully automated tunnel furnace gold bar production line is, how it works, and its impact on the gold industry.

What is a fully automatic tunnel furnace gold bar production line?

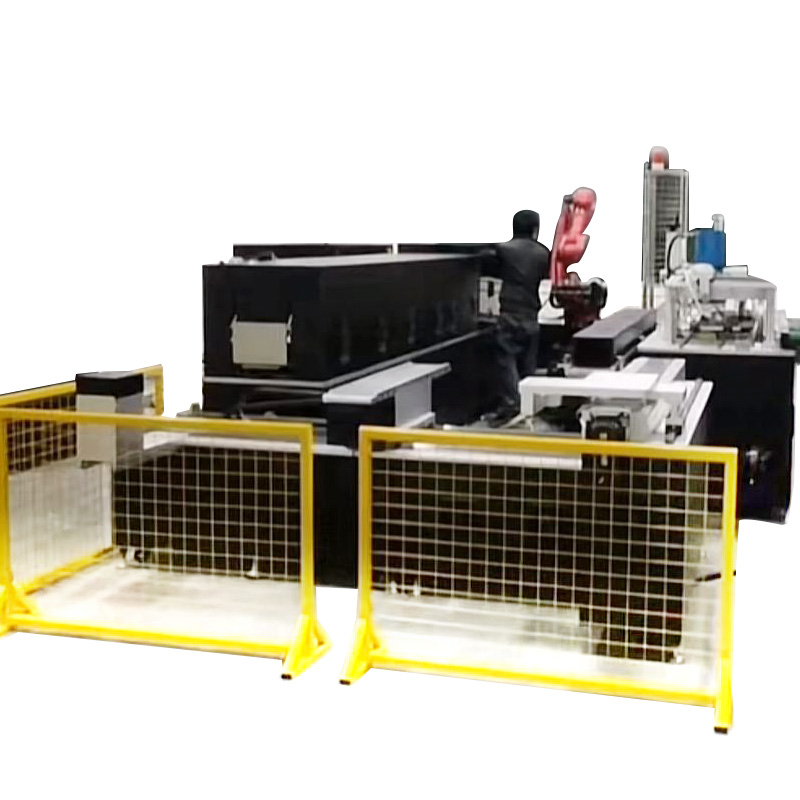

The fully automatic tunnel furnace gold bar production line is an advanced system specially designed for automated gold bar production. It consists of a series of interconnected machines and equipment that work seamlessly together to transform raw materials into finished gold bars. The entire process is fully automated without manual intervention, significantly reducing the risk of human error.

A key component of the line is the tunnel furnace, which is a furnace specifically designed to melt and refine gold. The furnace is equipped with an advanced temperature control system and sensors to ensure precise and consistent heating of the gold material. In addition, the production line includes various conveyors, molds, cooling systems and quality control mechanisms to streamline the entire manufacturing process.

The tunnel furnace gold silver bar production line includes

1. Metal granulator

2. Sieving with vibration system and drying system

3. Transfer vacuum system

4. Dosing system

5. Tunnel gold bar casting system

6. Cleaning and polishing system

7. Dot marking system

8. Logo stamping

9. Packing system

How does it work?

The fully automated tunnel furnace gold bar production line operates through a series of interrelated stages, each designed to perform a specific task in the gold bar manufacturing process. The process begins by loading raw gold material into a furnace, where it is melted and refined to remove impurities. The temperature and duration of heating are carefully controlled to achieve the desired purity and consistency of the molten gold.

After the gold material is refined, it is poured into molds and shaped into the desired gold bar shape. The molds are precisely designed to produce gold bars of various sizes and weights to meet the diverse needs of the market. After the gold solidifies, it is sent through a cooling system to stabilize its structure and temperature.

Quality control is a key aspect of the production line, with advanced inspection systems integrated to ensure the gold bars meet the highest standards of purity and quality. Any deviations or defects are promptly identified and resolved, ensuring only perfect gold bars are produced.

Impact on the gold industry

The introduction of the fully automatic tunnel furnace gold bar production line has had a profound impact on the gold industry. This advanced technology has revolutionized the manufacturing process, delivering several key benefits that are reshaping the industry.

First and foremost, automation of production processes significantly increases efficiency and productivity. With minimal manual intervention, the line can run continuously, maximizing output and reducing production time. This allows gold refiners and manufacturers to meet the growing demand for gold bars more effectively and efficiently.

Additionally, the precision and consistency achieved through automation improves the quality of the gold bars produced. Advanced temperature control systems and quality testing mechanisms ensure that gold bars meet the highest purity standards, instilling confidence in consumers and investors.

In addition, the fully automatic tunnel furnace gold bar production line improves safety and reduces the environmental impact of gold bar manufacturing. By minimizing human involvement in the production process, the risk of accidents and injuries is significantly reduced. Additionally, the efficient use of energy and resources in automated production lines contributes to a more sustainable and environmentally friendly approach to gold bar production.

Furthermore, the adoption of this advanced technology makes gold manufacturers more competitive in the global market. The ability to produce high-quality gold bars at a faster rate gives them a strategic advantage, allowing them to meet the needs of international buyers and expand their market reach.

In summary, the fully automated tunnel furnace gold bar production line represents a significant advance for the gold industry. Its automated and precise manufacturing processes improve the efficiency, quality and competitiveness of gold bar production. As demand for gold continues to rise, this innovative technology will play a key role in meeting market demand and shaping the future of the gold industry.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur