Tilting Induction Melting Machine For Gold Silver Copper 2kg 3kg 4kg 5kg 6kg

Features

Hasung Dual Use gold and platinum melting furnace can efficiently and effortlessly melt platinum, silver, gold, palladium and certain alloys.

The compact size of the platinum melting furnace makes it convenient to move about.

Hasung multipurpose gold and platinum melting furnace is also suitable for small scale melting because it melts about 1g to 2kg of metals at once, therefore, small businesses that require melting need not worry about getting a melting furnace that only meets their melting needs.

The power utilization of the platinum melting furnace is 15kw, this means that energy is saved when melting with the platinum melting furnace and you don’t have to worry about extra spending on extra power.

Hasung multipurpose gold and platinum melting furnace can meet the melting needs at a jewelry store, recreational metal diggers, research institutes and recycling old metals.

Hasung multi-purpose gold and platinum melting furnace is environmentally safe to use such that the furnace does not generate harmful gases or make disturbing noise. It is also safe for workers to operate as molten metal spillage does not occur.

The melting time is very fast, the platinum melting furnace melts at 2100℃ within 2 minutes, thereby, increasing your work and production efficiency.

All metals melted with our platinum melting furnace usually have a uniform consistency so that when such metal is cast, it has a high-quality finish.

The electromagnetic induction stirring function present within the platinum melting furnace makes the melting process efficient by transferring heat equally and all parts of the metal are melted evenly. This also means that all heat required for melting is totally utilised within the furnace, hence, no increase in temperature of the melting environment.

The in-built water-cooling system present within the furnace makes the furnace melting temperature to be controlled, thereby preventing overheating.

The induction heating technology present within the platinum melting furnace makes the electromagnetic induction possible, which means that all energy that is required for melting is completely utilized within the melting furnace.

The platinum melting furnace is very easy to operate. The control panel makes it easy for you to control and monitor the melting process.

The Hasung multi-purpose gold and platinum melting furnace is environmentally safe as no heat is caused during use, no gas is released and no noise occurs when melting with the platinum melting furnace.

The melting capacity of any melting surface reaching up to 2100℃ would normally consume excess power, but our gold melting equipment for sale only requires 15kw to begin melting making it cost-effective.

All 8kg melting is done efficiently in 3 minutes, an undefeatable feature of the gold melting equipment for sale. The speed of melting helps you to meet all melting demands faster and more easily.

Gold, silver, bronze, copper, platinum and other alloys can all be melted with our gold melting equipment. This enables you to save money on other melting equipment.

The water pump system present in our gold smelting equipment makes it maintain a normal temperature when melting is ongoing. Thereby, you save money on cooling equipment.

Our gold melting equipment is suitable to melt metals for research and teaching, foundries, recycling metals in jewelry stores, etc.

In respect to its impact on the environment, the noise of the gold and silver melting equipment during the process of melting is relatively low and there is no emission of gas, smoke or dust is also low.

Compared to resistance furnaces and propane burners, Hasung gold melting equipment ensures no loss of metals during the melting process, making our melting equipment more efficient than both resistant furnaces and propane burners.

Our gold and silver melting equipment can work continuously for as long as 24 hours.

The operator of the gold melting equipment has a total control of the melting parameters. Should an error occur, the omni-directional warning system helps to raise alarms when potentially harmful points are reached during melting, thereby ensuring the safety of the user.

Maintenance of the gold and silver melting equipment is easy as the crucibles are detachable and can be cleaned after each melting process.

Technical Parameters

| Model No. | HS-TF2 | HS-TF3 | HS-TF4 | HS-TF5 | HS-TF6 | HS-TF8 | HS-TF10 |

| Power | 8KW/15KW | 15KW | 15KW / 20KW | ||||

| Voltage | 380V, 50Hz, 3 phases | ||||||

| Max Temp | 1600°C | ||||||

| Melting Time | 2-3 min. | 3-5 min. | 3-6 min. | 4-8 min. | 5-8 min. | 5-8 min. | 6-8 min. |

| Temp Accuracy | ±1°C (using PID control for optional) | ||||||

| PID temp control | Optional | ||||||

| Capacity (Gold) | 2KG | 3KG | 4KG | 5KG | 6KG | 8KG | 10KG |

| Application | Gold, K gold, silver, copper and other alloys | ||||||

| Cooling type | Water chiller(sold separately) or Running water (water pump) | ||||||

| Heating method | Germany IGBT Induction heating technology | ||||||

| Dimensions | 90x48x100cm | ||||||

| Net Weight (approx.) | 90kg | 90kg | 100kg | 110kg | 120kg | 130kg | 160kg |

| Shipping Weight (approx.) | 160kg | 175kg | 180kg | 190kg | 200kg | 220kg | 220kg |

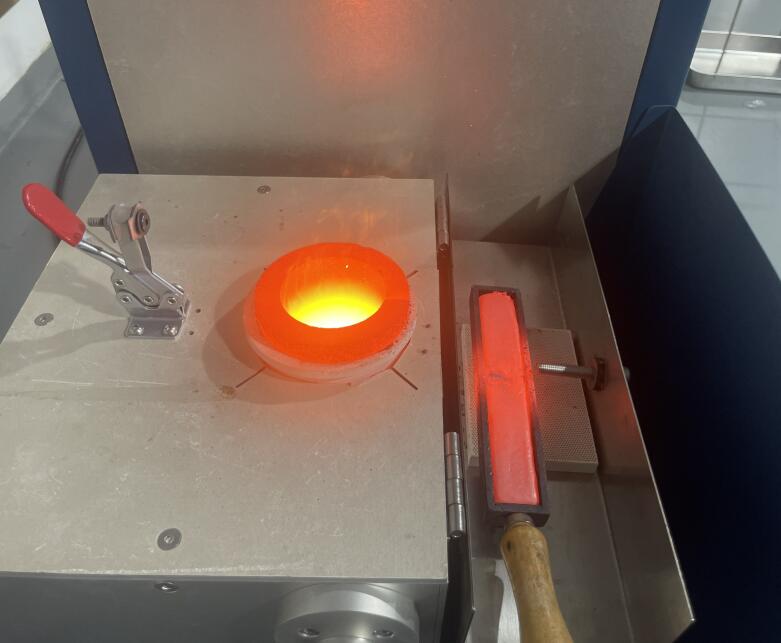

Product Display

-18.png)

Title: Advantages of Hasung manual tilt casting induction melting furnace

In the world of metal casting and casting operations, manual tilt-cast induction melting furnaces have become an indispensable tool due to their efficiency, safety and innovation. This advanced furnace design offers multiple benefits to operators and manufacturers, making it a popular choice within the industry. In this blog, we will explore the many benefits of a manual tilt-cast induction melting furnace and how its innovative features, such as a rotating tray for graphite molds and high-quality workmanship, contribute to its superior performance.

Manual tilt pour induction melting furnaces offer a range of advantages that make them a valuable asset in metal casting operations. One of the main advantages of this furnace is its manual tilt function, which allows precise control of the pouring process. Not only does this ensure consistent and even pouring, it also minimizes the risk of splashes or spills, providing a safer working environment for operators. The ability to manually tilt the furnace gives operators greater flexibility and control, allowing them to pour molten metal with ease and precision.

In addition, the innovation of the graphite mold rotating tray makes the Hasung manual tilting pouring induction melting furnace different from traditional melting equipment. This innovative feature enables the furnace to accommodate multiple molds, thereby increasing the efficiency and productivity of the casting process. Rotating pallets allow for seamless mold changes, reducing downtime and simplifying production. Additionally, the furnace's high-quality craftsmanship ensures durability and reliability, making it a long-term investment for foundries and metal casting facilities.

Manual tilt pour induction melting furnaces offer a range of advantages that make them a valuable asset in metal casting operations. One of the main advantages of this furnace is its manual tilt function, which allows precise control of the pouring process. Not only does this ensure consistent and even pouring, it also minimizes the risk of splashes or spills, providing a safer working environment for operators. The ability to manually tilt the furnace gives operators greater flexibility and control, allowing them to pour molten metal with ease and precision.

In addition, the innovation of the graphite mold rotating tray makes the manual tilting pouring induction melting furnace different from traditional melting equipment. This innovative feature enables the furnace to accommodate multiple molds, thereby increasing the efficiency and productivity of the casting process. Rotating pallets allow for seamless mold changes, reducing downtime and simplifying production. Additionally, the furnace's high-quality craftsmanship ensures durability and reliability, making it a long-term investment for foundries and metal casting facilities.

In addition to safety and innovation, manual tilt-and-cast induction melting furnaces also offer significant advantages in terms of energy efficiency and cost-effectiveness. The induction heating technology used in these furnaces melts metal quickly and precisely, reducing energy consumption and operating costs. This makes the furnace not only environmentally friendly, but also economically viable for foundries and metal casting facilities. The ability to achieve high melting efficiency while minimizing energy consumption is a key advantage of manual tilt-cast induction melting furnaces.

Additionally, manual tilt pour induction melting furnaces are designed to meet the diverse needs of metal casting operations, offering versatility and adaptability for a variety of applications. Whether for small-scale production or large-scale casting operations, the furnace can be adapted to different melting capacities and metal types, making it a versatile and practical solution for manufacturers. The flexibility of the furnace allows for seamless integration into existing production processes, increasing overall efficiency and productivity.

In summary, manual tilt-cast induction melting furnaces offer numerous advantages that make them an essential tool for metal casting and foundry operations. Its safety features, innovative design, high-quality craftsmanship, energy efficiency and versatility make it a valuable investment for manufacturers looking to optimize their casting processes. With its precise control of the pouring process, innovative rotating tray for graphite molds and cost-effective operation, this furnace is a game changer for the metal casting industry. As the demand for high-quality, efficient melting equipment continues to grow, manual tilt-cast induction melting furnaces become a reliable and advanced solution for manufacturers looking to increase their casting capabilities.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur