Video Show

How to Make Shiny Gold Bar ?

How are traditional gold bars made? What a surprise!

The production of gold bars is still very new to most people, just like a mystery. So, how are they made? First, melt the recovered gold jewelry or gold mine to obtain small particles

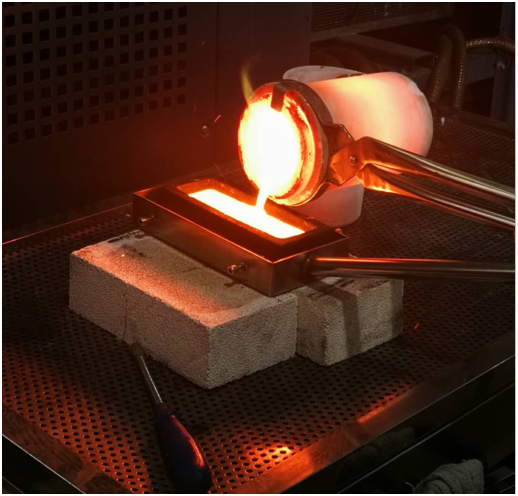

1. Using induction melting furnace to melt gold then pour gold liquid into the mold.

2. The gold in the mold gradually solidifies and becomes a solid.

3. After the gold is completely solidified, remove the gold nugget from the mold.

4. After taking out the gold, put it in a special place for cooling.

5. Finally, use the machine to engrave the number, place of origin, purity and other information on the gold bars in turn.

6. Workers who work here must be trained to not squint, just like a bank teller.

Gold bars, also known as gold bars, gold bars, and gold ingots, are bar-shaped objects made of refined gold, which are usually used by banks or traders for preservation, transfer, trade and investment. Its value depends on the purity and quality of the gold contained.

Nowdays Gold Bar Casting

Title: The Art of Gold Bar Making: A Step-by-Step Guide

Gold has always been a symbol of wealth and luxury, and the process of making gold bars is an art form in itself. From the initial melting of the gold to the final casting of the gold bars, each step requires precision and expertise. In this guide, we'll explore the complex process of gold bar making, from raw materials to finished product.

The first step in making gold bars is gathering raw materials. Gold comes in many forms, such as nuggets, dust, and even parts of other metals. Once raw gold is obtained, it needs to be purified to remove any impurities. This is usually done through a process called smelting, where the gold is heated to high temperatures to separate it from other materials. The end result is pure gold, which can be processed into gold bars.

Once the gold has been purified, it's time to melt it down. This is done using a furnace, which heats the gold to its melting point. Once the gold is in liquid form, it is poured into molds to form the shape of a gold bar. The mold is usually made of graphite because it can withstand the high temperatures required to melt the gold. The size and weight of gold bars may vary depending on the customer's specific requirements or the intended use of the gold.

After the gold is poured into the mold, it needs to cool and solidify. This process can take some time as the gold needs to reach a certain temperature before it can be removed from the mold. Once the bars solidify, they are carefully removed from the mold and inspected for any defects. Any excess material or rough edges are removed and the strips are polished to give them a smooth, shiny surface.

The last step in making gold bars is to mark them with the appropriate markings. This usually includes the purity of the gold, the weight of the gold bar, and the manufacturer's mark. These markings are very important in verifying the authenticity and quality of gold bars. Once the gold bars are stamped, they can be packaged and shipped to their final destination.

All in all, the process of making gold bars is a meticulous and precise art form that requires skill and expertise. From the initial purification of raw gold to the final stamping of gold bars, every step is critical to creating a high-quality product. Whether for investment purposes or as a symbol of luxury, gold bullion is a timeless and valuable commodity that continues to be in demand around the world.

Hasung’s Latest Vacuum Gold Bars Making Technology

1. Step1: Smelt for pure gold.

2. Step2: Make gold granules or make gold powders.

3. Step3: Weighing and casting gold bars with an ingot machine.

4. Step4: Stamping logos on the gold bars.

5. Step5: Dot peen number marking machine to mark serial numbers.

Why do You Choose Hasung Vacuum Gold Bar Casting Machine ?

Hasung Vacuum machine compare to other companies:

1. It’s a Big difference. other companies vacuum are controlled by time. They are not real time vacuum. They just pump it symbolically. Ours pumps to the set vacuum level and can maintain the vacuum. When they stop pumping, it is not a vacuum.

2. In other words, what they have are the vacuum setting time. For example, adding inert gas after one minute or 30 seconds is automatic. If it does not reach the vacuum, it will be converted to inert gas. It is In fact, the inert gas and the air are fed at the same time. It is not a vacuum at all. the vacuum cannot be maintained for 5 minutes. Hasung can maintain a vacuum for more than twenty hours.

3. We are not the same. We have drawn a vacuum. If you stop the vacuum pump, it can still maintain the vacuum. For a certain period of time,we will reach the set After setting the value,it can automatically switch to the next step and add inert gas.

4. The material we use is thicker and stronger which ensures machine quality. Hasung the original parts are from well-known domestic Japan and German brands.

May I cast Gold Bars of Different Sizes and Weights in the Machine?

This is very easily possible. At Hasung, making gold bars is what we pride in. Therefore, we are here to ensure that everything is possible. At the same time, we take good care of quality production. We can cast gold bars of different weights, such as 1oz, 100 grams, 500 grams, 1 kg, 400oz,12.5kg and 30kg bars. It all depends on what you need. All you have to do is let us know so that we show you how to book an appointment with our specialists. They will ensure that you get the most pleasant user experience. But clients are required to customize molds with different specifications.

Can I cast gold bars of different sizes and weights on the machine?

This is easy to do. At Hasung, manufacturing gold bars is our pride. Therefore, we are here to make sure that everything is possible. At the same time, we will properly keep high-quality products. We can cast gold bars of different weights, such as 1 ounce, 100 grams, 500 grams, 1 kg, 400 ounces, 12.5 kg and 30 kg gold bars. It all depends on your needs. All you have to do is let us know in order to show you how to make an appointment with our experts. They will ensure you get the most enjoyable user experience. But customers need to customize molds with different specifications.

What is the production cost of the vacuum rod casting machine?

The production cost of this highly innovative bar casting machine depends on many important factors. For example, before beginning the application process, you will have to know the amount of gold or silver to be minted into gold bars. Note that this will increase the total production cost, regardless of who works. You also need to calculate the amount of electricity needed and whether to hire someone to do the work for you. Based on the above, it may not be possible to provide an accurate budget for your production process. However, Hasung can help you reduce production costs through discounts and preferential prices. If you are not sure about any of them, you can visit our website to view the products we have prepared for you.

Can I get 999 purity gold bars in your machine?

This mainly depends on the nature of your raw materials. Hasung would like to inform you that the production of gold bars is a different process than the refining process. In addition, our vacuum casting machine cannot refine your raw materials. However, if you are interested in such services, we can help you optimize it. Therefore, if you provide us with extremely pure raw materials, you will only get gold bars of 999 purity. In order to avoid disappointing our customers, we usually let them know about these things before starting to cast their gold and silver into gold bars. If the raw material is 999, the finished product is also 999 and will not be contaminated.

How to install and use the machine? Can you come to our factory for service?

This is an important question of absolute honesty. So, to be honest, we will always provide user manuals and videos that can help you with the installation process. Our video quality is first-rate, and we firmly believe that if we can follow suit, the installation process will be 100% successful. However, if you are not sure, we can provide on-site engineers. Just want to let you know that you will be responsible for visas, round-trip air tickets, accommodation, local transportation and wages. However, we don’t think you need to do all of these things because the videos and manuals we provide are comprehensive and all-inclusive.

What kind of gas do we need to protect in the vacuum casting machine?

Both argon and nitrogen can ensure your safety during use. In addition, you also need to be equipped with the correct protective equipment to prevent accidents in the workplace. We are not saying that this is normal, but it is good to stay safe, right? Otherwise, as long as the correct measures are taken at each application level, our machines will function well. If you have any questions, please feel free to contact our support team. Most precious metals companies and investors prefer gold bars to coins because they are easier to stack. Moreover, compared with their counterparts in sovereign coins, most of them have a lower premium. At Hasung, we provide some of the best solutions, which is why you need to contact us before investing in minted gold bars.

The original gold rush principle:

The chemical properties of gold are very stable and generally do not react with other substances, so most of its free state exists in sand and stone. The density of gold is much greater than the density of sand and rock, close to ten times the density of sand and rock, so it is not easily washed away by water and is easier to settle.

Therefore, the original gold mining method is to wash the gold-containing sand with a lot of water. During the washing process, the collision particles of sand and stone are getting smaller and smaller. The gold-containing sand is enriched in the front section, and then the sand with high gold content is collected in the front section. The same method continues to enrich. Until the gold content reaches the required grade.

Now the method of extracting gold from alluvial gold

There are two main methods for refining sand gold into gold: one is the fire alchemy version;

One is the withdrawal of electricity rights. Pyrometallurgy is to first crush the ore, beneficiated by heavy sand method, enrich it, and then refine it in a furnace; electrolytic gold extraction uses sodium cyanide solution to dissolve the gold in the ore, and then extract the gold by electrolysis. With this refining method, the purity of gold can reach 99.9%.

Post time: Jul-04-2022