WIRE BONDING

KNOWLEDGE BASE FACT SHEET

What is Wire Bonding?

Wire bonding is the method by which a length of small diameter soft metal wire is attached to a compatible metallic surface without the use of solder, flux, and in some cases with the use of heat above 150 degrees Celsius. Soft metals include Gold (Au), Copper (Cu), Silver (Ag), Aluminum (Al) and alloys such as Palladium-Silver (PdAg) and others.

Understanding Wire Bonding Techniques and Processes for Micro Electronics Assembly Applications.

Wedge Bonding Techniques / Processes: Ribbon, Thermosonic Ball & Ultrasonic Wedge Bond

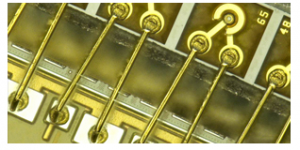

Wire bonding is the method of making interconnects between an integrated circuit (IC) or similar semiconductor device and its package or leadframe during manufacturing. It is also commonly used now to provide electrical connections in Lithium-ion battery pack assemblies.Wire bonding is generally considered the most cost-effective and flexible of the available microelectronic interconnect technologies, and is used in the majority of semiconductor packages produced today.There are several wire bonding techniques, comprising:Thermo-Compression Wire Bonding:

Thermo-compression wire bonding (combining to likely surfaces (usually Au) together under a clamping force with high interface temperatures, typically greater than 300°C, to produce a weld), was initially developed in the 1950’s for microelectronics interconnects, however this was quickly replaced by Ultrasonic & Thermosonic bonding in the 60’s as the dominant interconnect technology. Thermo-compression bonding is still in use for niche applications today, but generally avoided by manufacturers due to the high (often damaging) interface temperatures needed in order to make a successful bond.Ultrasonic Wedge Wire Bonding:

In the 1960’s Ultrasonic wedge wire bonding became the dominant interconnect methodology. Application of a high frequency vibration (via a resonating transducer) to the bonding tool with a simultaneous clamping force, allowed Aluminium and Gold wires to be welded at room temperature. This Ultrasonic vibration assists in removing contaminants (oxides, impurities, etc.) from the bonding surfaces at the start of the bonding cycle, and in promoting intermetallic growth to further develop and strengthen the bond. Typical frequencies for bonding are 60 – 120 KHz.The ultrasonic wedge technique has two main process technologies:Large (heavy) wire bonding for >100µm diameter wiresFine (small) wire bonding for <75µm diameter wiresExamples of typical Ultrasonic bonding cycles can be found here for fine wire and here for large wire.Ultrasonic wedge wire bonding uses a specific bonding tool or “wedge,” usually constructed from Tungsten Carbide (for Aluminium wire) or Titanium Carbide (for Gold wire) depending on the process requirements and wire diameters; ceramic tipped wedges for distinct applications are also available.Thermosonic Wire Bonding:

Where supplementary heating is required (typically for Gold wire, with bonding interfaces in the range of 100 – 250°C), the process is called Thermosonic wire bonding. This has great advantages over the traditional thermo-compression system, as much lower interface temperatures are required (Au bonding at room temperature has been mentioned but in practice it is unreliable without additional heat).Thermosonic Ball Bonding:

Another form of Thermosonic wire bonding is Ball Bonding (see the ball bond cycle here). This methodology uses a ceramic capillary bonding tool over the traditional wedge designs to combine the best qualities in both thermo-compression and ultrasonic bonding without the drawbacks. Thermosonic vibration ensures the interface temperature remains low, while the first interconnect, the thermally-compressed ball bond allows the wire and secondary bond to be placed in any direction, not in-line with the first bond, which is a constraint in Ultrasonic wire bonding. For automatic, high volume manufacture, ball bonders are considerably faster than Ultrasonic / Thermosonic (Wedge) bonders, making Thermosonic ball bonding the dominant interconnect technology in microelectronics for the last 50+ years.Ribbon Bonding:

Ribbon bonding, utilising flat metallic tapes, has been dominant in RF and Microwave electronics for decades (ribbon providing a significant improvement in signal loss [skin effect] versus traditional round wire). Small Gold ribbons, typically up to 75µm wide and 25µm thick, are bonded via a Thermosonic process with a large flat-faced wedge bonding tool.Aluminium ribbons up to 2,000µm wide and 250µm thick can also be bonded with an Ultrasonic wedge process, as the requirement for lower loop, high density interconnects has increased.

What is gold bonding wire?

Gold wire bonding is the process by which gold wire is attached to two points in an assembly to form an interconnection or an electrically conductive path. Heat, ultrasonics, and force are all employed to form the attachment points for the gold wire.The process of creating the attachment point begins with the formation of a gold ball at the tip of the wire bond tool, the capillary. This ball is pressed on the heated assembly surface while applying both an application-specific amount of force and a frequency of 60kHz - 152kHz of ultrasonic motion with the tool.Once the first bond has been made, the wire will be manipulated in a tightly controlled manner to form the appropriate loop shape for the assembly’s geometry. The second bond, often referred to as the stitch, is then formed on the other surface by pressing down with the wire and using a clamp to tear the wire at the bond.

Gold wire bonding offers an interconnection method within packages that is highly electrically conductive, nearly an order of magnitude greater than some solders. In addition, gold wires have a high oxidation tolerance compared to other wire materials and are softer than most, which is essential for sensitive surfaces.

The process can also vary based on the needs of the assembly. With sensitive materials, a gold ball can be placed on the second bonding area to create both a stronger bond and a “softer” bond to prevent damage to the surface of the component. With tight spaces, a single ball can be used as a starting point for two bonds, forming a “V” shaped bond. When a wire bond needs to be more robust, a ball can be placed on top of a stitch to form a security bond, increasing the stability and strength of the wire. The many different applications and variations to wire bonding are nearly limitless and can be achieved through use of the automated software on Palomar’s wire bond systems.

Wire bonding development:

Wire bonding was discovered in Germany in the 1950's through a fortuitous experimental observation and has subsequently been developed into a highly controlled process. Today it is used extensively for electrically interconnecting semiconductor chips to package leads, disk drive heads to pre-amplifiers, and many other applications which allow everyday items to become smaller, "smarter", and more efficient.

Bonding Wires Applications

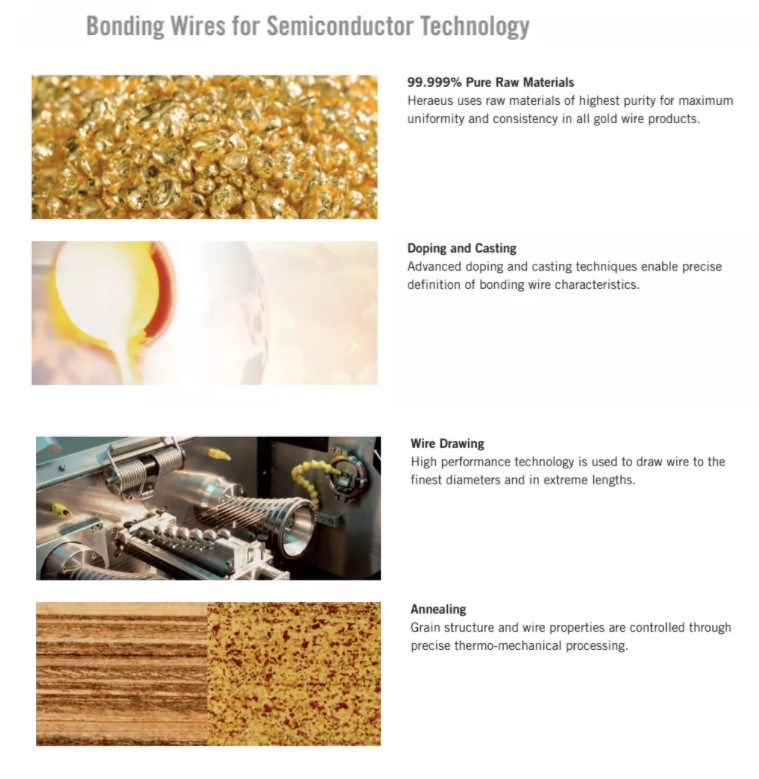

The increasing miniaturization in electronics has resulted

in bonding wires becoming important constituents of

electronic assemblies.

For this purpose fine and ultrafine bonding wires of

gold, aluminum, copper and palladium are used. Highest

demands are made on their quality, especially with regard

to the uniformity of the wire properties.

Depending on their chemical composition and specific

properties, the bonding wires are adapted to the bonding

technique selected and to automatic bonding machines as

well as to the various challenges in assembly technologies.

Heraeus Electronics offers a wide product range

for various applications of the

Automotive industry

Telecommunications

Semiconductor manufacturers

Consumer goods industry

Heraeus Bonding Wire product groups are:

Bonding wires for applications in plastic filled

electronic components

Aluminum and aluminum alloy bonding wires for

applications which require low processing temperature

Copper bonding wires as a technical and

economical alternative to gold wires

Precious and non-precious metal bonding ribbons for

electrical connections with large contact areas.

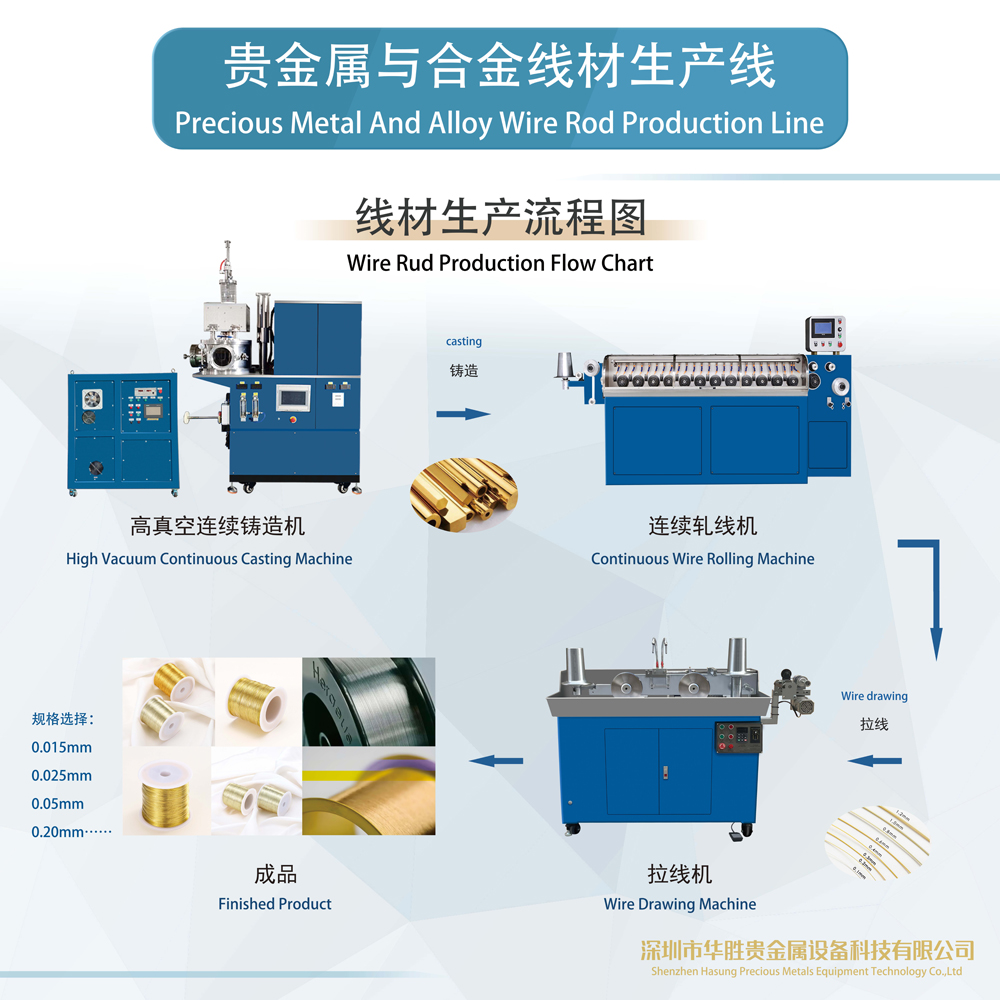

Bonding Wires Production Line

Post time: Jul-22-2022