Video Show

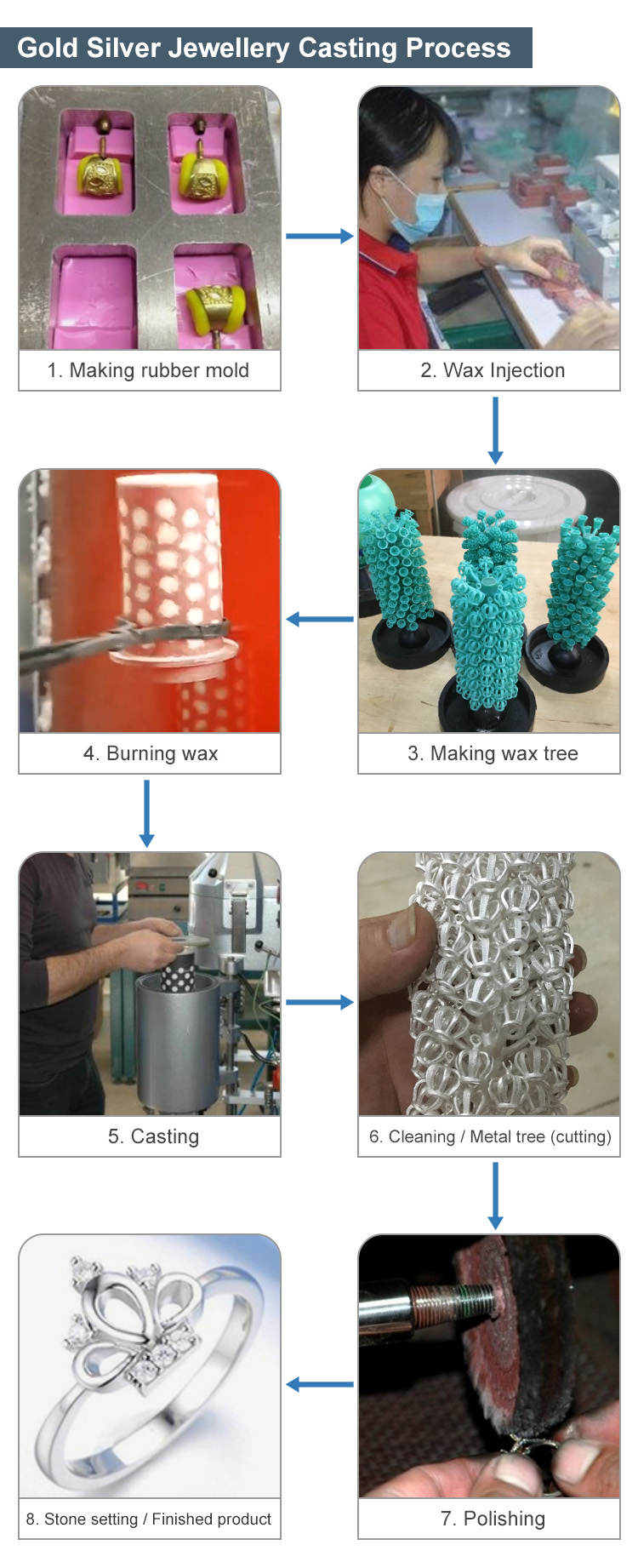

Steps for Casting Jewelry via the Vacuum Pressure Jewelry Casting Equipment

1.The first step is to prepare the wax molds. It’s advisable you weld the wax molds into a wax mold tree (the wax molds can be copied in batches by a wax injection machine or printed by a 3D printer).

2.Make a lost wax casting mold with a vacuum powder mixer.

3.Use a wax burnout furnace for melting/ burning the wax out of the mold.

4.Melt the precious metal and fill in the entire plaster mould by the vacuum pressure casting equipment.

5.The rough piece of the Jewelry is formed after casting.

6.Remove the excess plaster with a plaster water jet cleaning machine, and you are good to market your Jewelry.

You can bank with Hasung to provide you with a one-stop production line solution. The production package ranges from on-site guidance, equipment, and engineers to help you scale through the process.

Hasung is committed to solving your casting problems while proffering step by step guide to precious metals. We have been at the forefront of the Jewelry casting industry fo 20+ years. We possess professional and meticulous engineers’, on-site training service, and a casting experience of more than ten years.

Hasung has helped build dozens of jewelry casting production lines in places like India, Dubai, Australia, Qatar, etc. Our engineers have rich experience in crafting a complex and unique piece of Jewelry.

Hasung Precious Metals Equipment advantages

1.The product has uniform color and no segregation:

The porosity is reduced, and the density is higher and constant, reducing post-processing work and reducing loss.

2.Better material fluidity and mold filling, lower enthusiasm risk:

Vibration improves material flow, and the material structure is more compact. Improve shape filling and reduce the risk of hot cracks

3.The grain size is reduced to 50%:

Solidify with a finer and more uniform structure

4.Better and more stable material properties:

The tensile strength and elasticity are increased by 25%, and the subsequent processing performance is improved.

Why do You Choose Hasung Vaccum Pressure Casting Machine ?

Hasung Vaccum Casting machines compare to other companies

1. It’s a Big different. other companies vacuum are controlled by time.They are not vacuum.They just pump it symbolically.When they stop pumping, it is not a vacuum.Ours pumps to the set vacuum level and can maintain the vacuum.

2. In other words, what they have are the vacuum setting time.For example, adding inert gas after one minute or 30 seconds is automatic.If it does not reach the vacuum, it will be converted to inert gas. It is In fact, the inert gas and the air are fed at the same time. It is not a vacuum at all. the vacuum cannot be maintained for 5 minutes.Hasung can maintain a vacuum for more than twenty hours.

3.We are not the same. We have drawn a vacuum. If you stop the vacuum pump,it can still maintain the vacuum. For a certain period of time,we will reach the set After setting the value,it can automatically switch to the next step and add inert gas

4.Hasung the original parts are from well-known domestic Japan and German brands.

5. Hasung machines are well designed which is easy to operate. It is good for a beginner.

Post time: Jul-04-2022