Platinum water atomization powder equipment

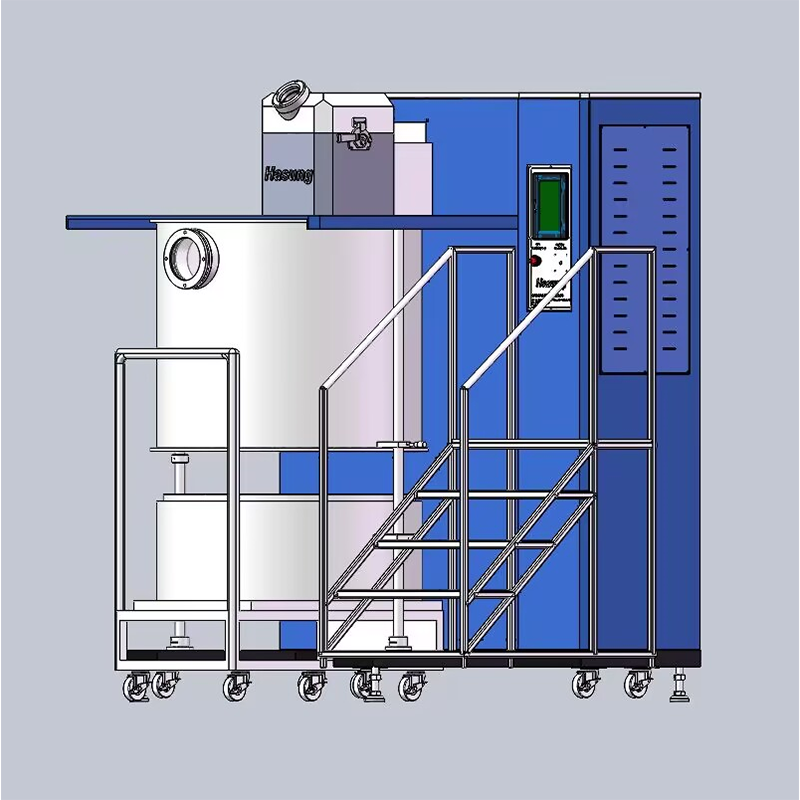

The specific process is that the alloy (metal) is melted and refined in an induction furnace, and the melted metal liquid is poured into an insulated crucible and enters a guide pipe. At this time, a high-pressure liquid flow is sprayed from a spray plate, and the metal liquid is crushed into extremely small droplets by impact. The metal droplets solidify and fall in the atomization tower, and then fall into the powder collection tank for collection. The collected powder slurry is filtered and dehydrated, and finally dried, screened, weighed, and packaged into finished products.

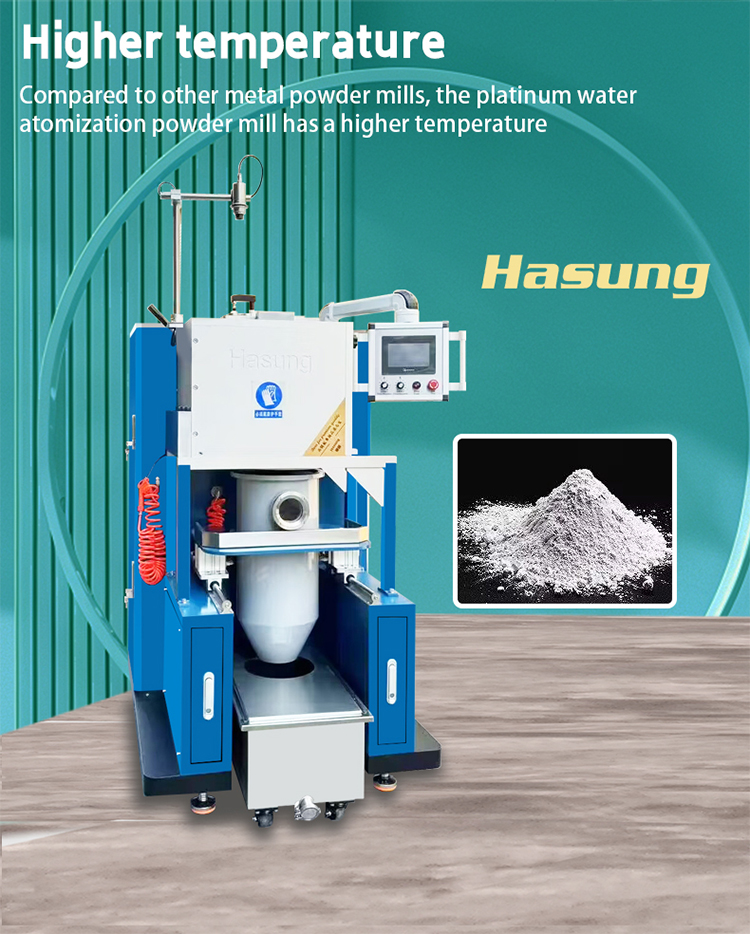

The metal powder produced by high-pressure water atomization has the following characteristics: irregular or nearly spherical morphology, high purity, low oxygen content, fast solidification speed, etc. It is widely used in the field of atomization of non-ferrous metal powders such as platinum powder, palladium powder, rhodium powder, iron powder, copper powder, stainless steel powder, alloy powder, etc.

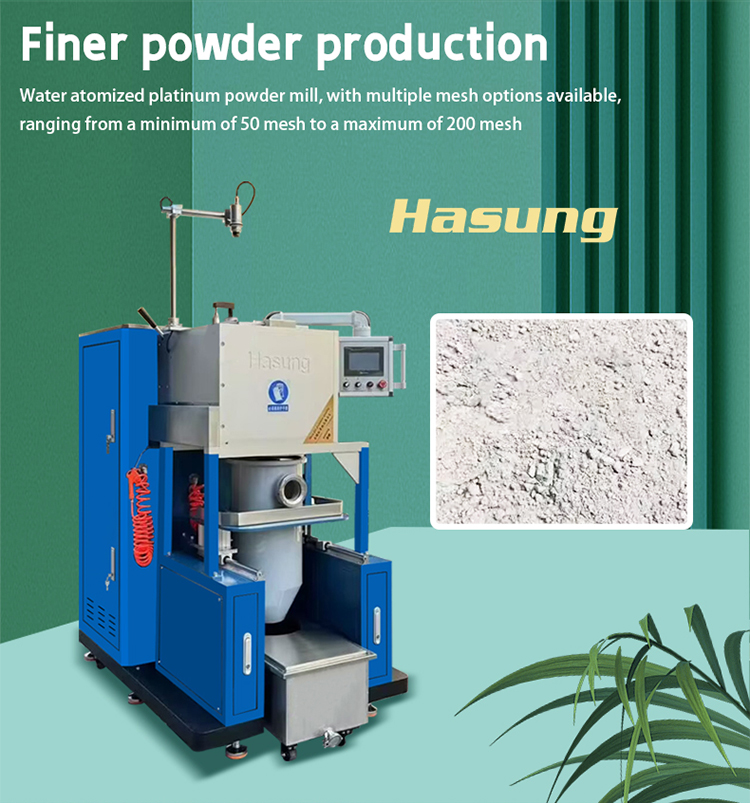

Water atomization is actually a special water atomization process, which uses the strong negative pressure generated by high-pressure water jet to drive the gas in the atomization chamber to participate in atomization. Due to the intervention of a large amount of gas, the cooling rate of the powder is reduced, and the morphology of the powder is improved. Therefore, finer particles and more regular shapes of powder can be produced. Currently, it is mainly used for the production of stainless steel powder and amorphous powder.

Technical parameters:

| Model No. | HS-MIP2 | HS-MIP4 | HS-MIP6 | HS-MIP10 | HS-MIP20 |

| Voltage | 380V, 50/60Hz 3 Phase | ||||

| Power | 15KW * 2 | 20KW * 2 | 25KW * 2 | 40KW * 2 | |

| Capacity (Pt) | 2kg | 4kg | 6kg | 10kg | 20kg |

| Melting speed | 3-5 min. | 4 - 6 min. | 4-6 min. | 6-8 min. | 10-15 min. |

| Max Temp | 2200°C | ||||

| Temp. Detector | Infrared pyrometer | ||||

| Temp Accuracy | ±1°C | ||||

| Inert gas | Argon / Nitrogen | ||||

| Application metals | Automatic lubrication | ||||

| Application metals | Platinum, Palladium, Stainless Steel, Gold, K gold, silver, copper and other alloys | ||||

| Water jet device | Built-in | ||||

| High pressure pump | Built-outside | ||||

| Particle size | 50#-200# (adjustable.) | ||||

| Operation method | 7" Touch screen + Siemens PLC intelligent controller | ||||

| Water cooling temp. required | 18-26°C | ||||

| Machine size | 1020*1320*1680mm | 1300×1350×1900mm | |||

| Weight | approx. 560kg | Approx. 800kg | |||

| High pressure water pump | |||||

| Voltage | 380V, 50/60Hz 3 Phase | ||||

| Power | 22KW | ||||

| Water pressure | 23Mpa | ||||

| High pressure water supply | 90 ltr./min. | ||||

| Water atomizing pressure max. flow | approx. 50 ltr./min. | ||||

| Water pump dimensions | 142x102x128cm | ||||

| Water pump weight | approx.630kg | ||||

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur