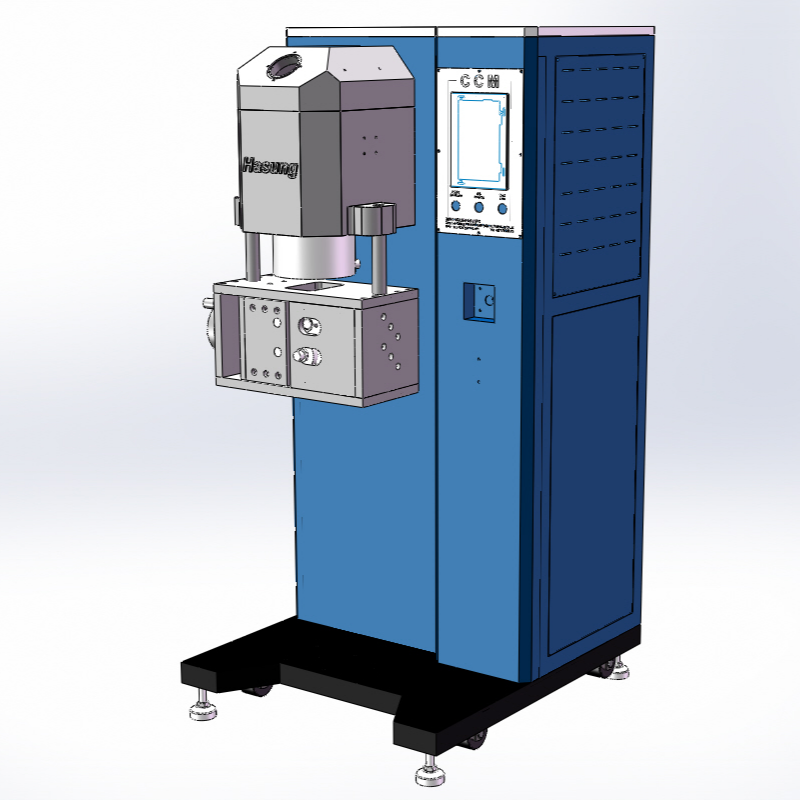

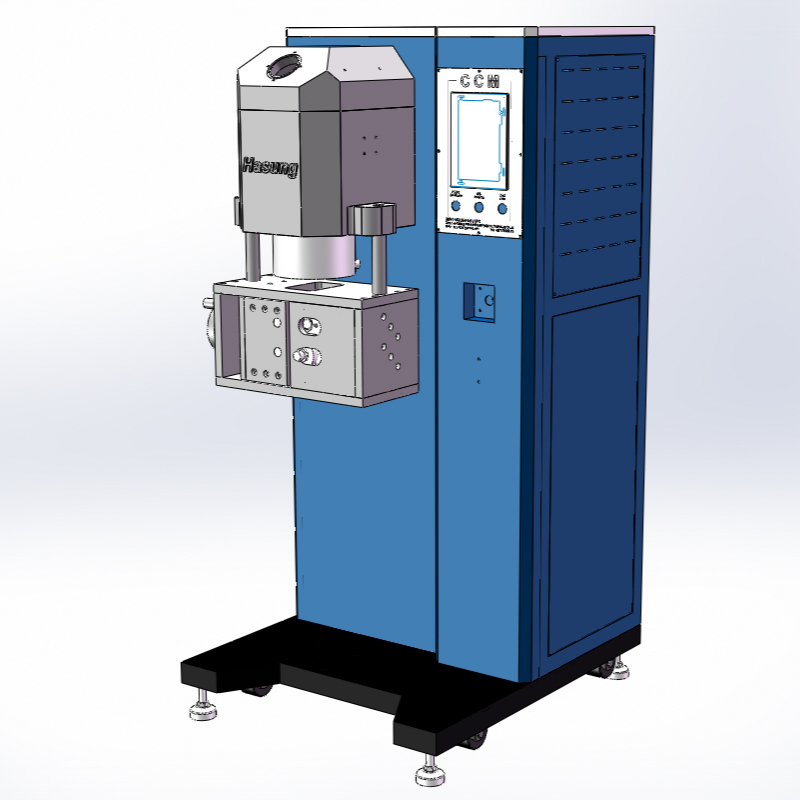

OEM Supply Manufacturing Gold Silver Continuous Copper Rod Casting Machine Equipment

The very abundant projects administration experiences and 1 to just one provider model make the higher importance of company communication and our easy understanding of your expectations for OEM Supply Manufacturing Gold Silver Continuous Copper Rod Casting Machine Equipment, We’ve professional goods knowledge and rich experience on manufacturing. We often imagine your achievements is our company!

The very abundant projects administration experiences and 1 to just one provider model make the higher importance of company communication and our easy understanding of your expectations for China Gold Silver Continuous Casting Machine and Upward Copper Rod Casting Machine, If you are for any reason unsure which product to select, do not hesitate to contact us and we will be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows “Survive by good quality, Develop by keeping good credit. ” operation policy. Welcome all the clients old and new to visit our company and talk about the business. We’ve been looking for more and more customers to create the glorious future.

Technical Parameters

| Model No. | HS-CC1 | HS-CC2 | HS-CC3 | HS-CC4 | HS-CC5 | HS-CC6 | HS-CC8 | HS-CC10 |

| Voltage | 220V Single phases / 380V 50/60Hz,3 phase | 380V 50/60Hz,3 phase | ||||||

| Power | 5KW / 8KW | 10KW | 15KW | 15KW / 20KW | ||||

| Max. Temp. | 1500°C | |||||||

| Melting speed | 2-5 mins. | 3-5mins. | 3-5mins. | 4-6mins. | 5-8mins. | |||

| Capacity (Gold) | 1kg | 2kg | 3kg | 4kg | 5kg | 6kg | 8kg | 10kg |

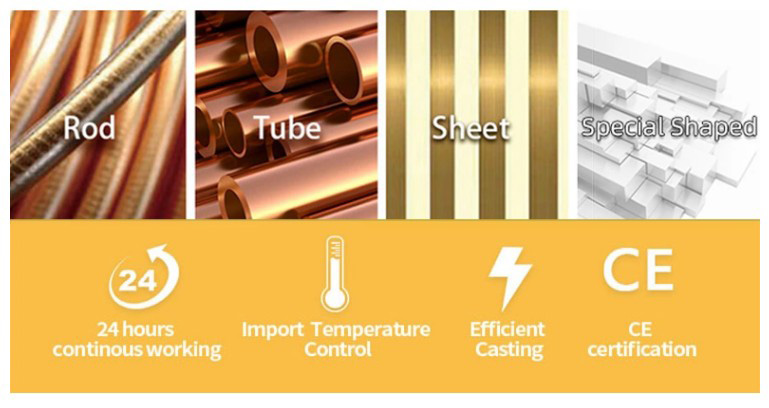

| Suitable for | Gold, karat gold, silver, copper | |||||||

| Casting product | Rods, strips, plates, hexagon, square, etc. | |||||||

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | |||||||

| control system | Taiwan / Siemens PLC+Human-machine interface intelligent control system (optional) | |||||||

| Vacuum (Optional) | High quality vacuum pump/Original German vacuum pump -98Kpa | |||||||

| Heating method | Germany IGBT Induction heating technology | |||||||

| Cooling method | Running water / water chiller | |||||||

| Dimensions | 680x880x1530mm | |||||||

| Weight (approx.) | 150KG | 150KG | 180KG | 180KG | 180KG | 180KG | 180KG | 180KG |

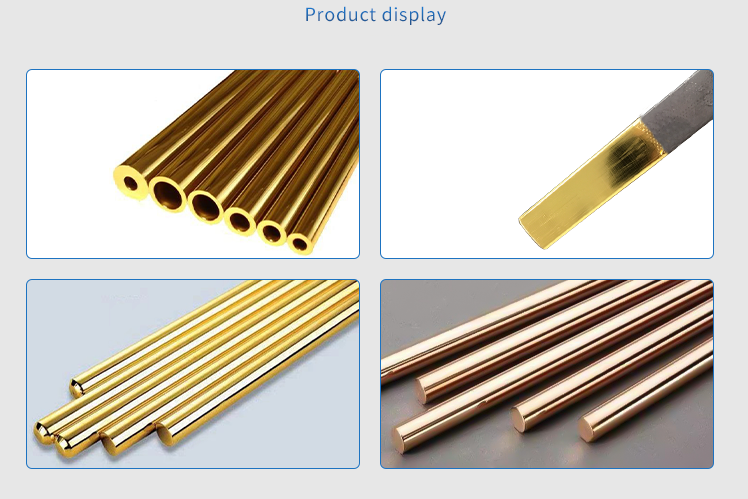

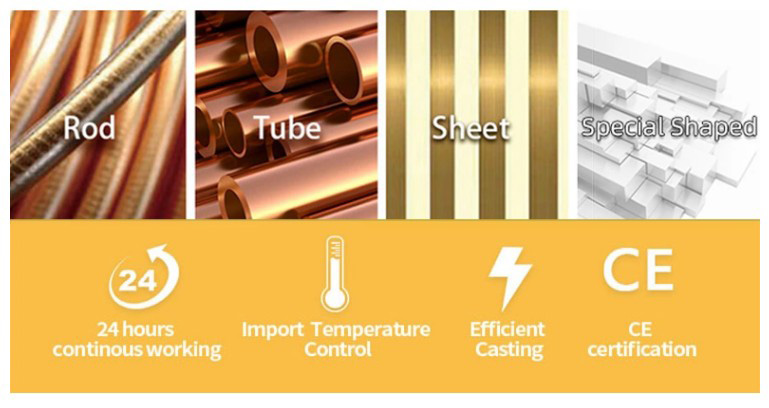

Product Display

Wire Processing Equipment

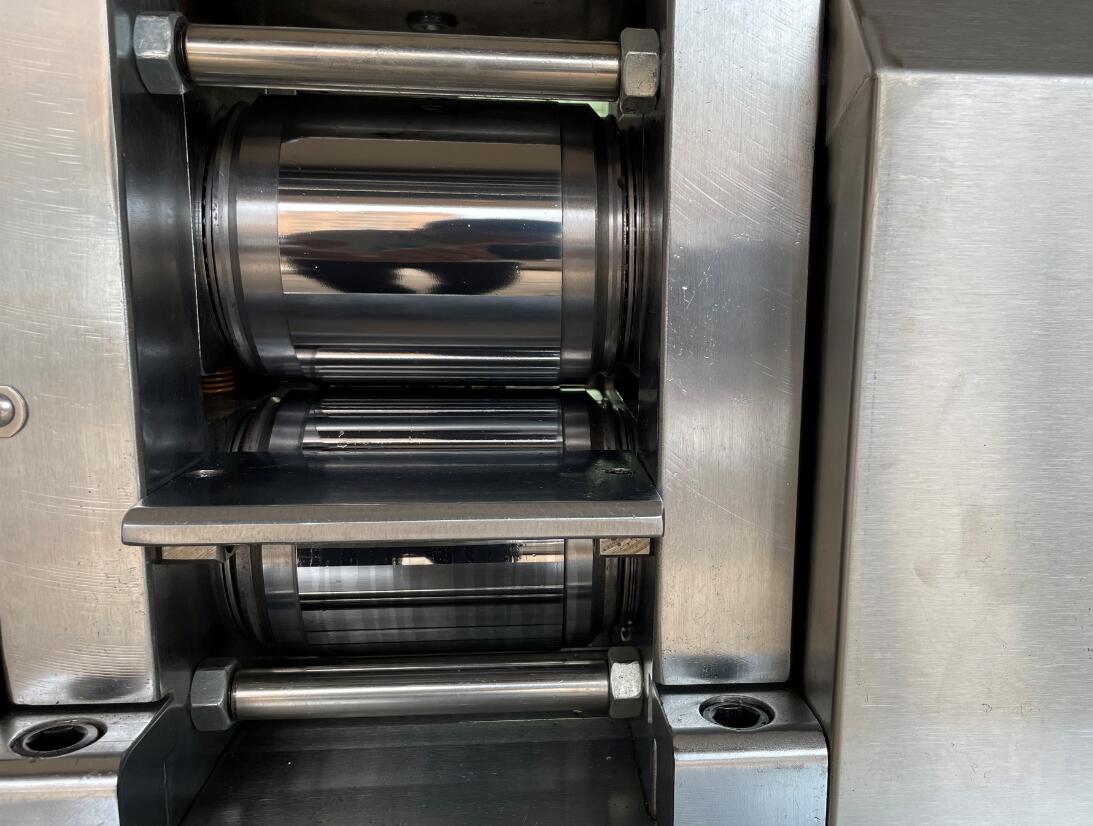

Wire Continuous Rolling Mill for Gold Silver Copper

Model No.: HS-3000

Rolling mill Machine Wire Drawing Machine for Gold Silver Chain Wire

It has a fully automatic 12-axis speed adjustment system to ensure that there is no slippage in the middle of each roll, and the working speed is continuously adjusted. The staff only needs to pass the material through each roller in the order of the rollers at one time, without adjusting the lifting roller. It is used for precious metals wire processing, widely used for metal wires manufacturing industry.

| Voltage | 380V, 50Hz, 3 Phases |

| Power | 8KW |

| Roller diameter | 96mm(Roller material: SKD11) |

| Roller quantity | 12 pairs |

| Processing material range | input 8.2×8.2mm; output 3.5×3.5mm or input 3.5×3.5mm; output 1.0×1.0mm |

| Max rolling speed | 45 m/min. (925 silver: approx. 4.9kg) |

| Dimensions | 2800x900x1300mm |

| Weight: approx | 2500kg |

| Control system | frequency speed control, motor drive rolling |

| Wire collection way | Sagging Gravity take-up |

| Material cooling | Spray lubricating fluid cooling |

| Application | Gold, K-gold, Silver, Copper, alloy. |

Heavy Duty Wire Drawing Machine for Gold Silver Copper

Model No.: HS-1126

It is a heavy duty type wire drawing system, application for gold, silver, copper, etc. Drawing ability up to 8mm, minimum size could be 0.2mm. It is used for precious metals wire processing, widely used for metal wires manufacturing industry.| Voltage | 380V, 50Hz, 3 Phases |

| Power | 5.5KW*2 |

| Drawing wire diameter | 0.2-8mm |

| Roller hardness | 60-62 HRC |

| Processing material range | gold, K-gold, Silver, Copper, alloy, etc |

| Max rolling speed | 32m/min. |

| Motor speed | 36rpm/min. (speed control) |

| Dimensions | 1900x800x1400mm |

| Weight: approx | approx. 900kg |

| Wire collection device | Included |

| Material cooling | Spray water cooling |

8HP Double Head Electric Wire Rolling Mill (double speed)

Heavy duty type double head wire rolling mill machine is applied for jewellery factories and precious metals industry. It is equipped with wire winding device. Easily for wire manufacturers.

For jewellery factories, mostly they use it making wires, then making many types of link chains for gold and silver, copper materials. Wire and sheet sizes could be customized by this machine according to requests.

Specification

| Model No. | HS-D8HP |

| Voltage | 380V, 50/60Hz |

| Power | 5.5KW |

| Roller | diameter 130/120 × width 188mm |

| Roller hardness | 60-61 ° |

| Dimensions | 1080 × 1180 × 1480mm |

| Weight | Approx. 850kg |

| Additional function | automatic lubrication; gear transmission |

| Features |

Rolling 0.9-10.5mm square wire; double speed; smooth surface of the wire, accurate size, no low front loss; automatic take-up; electrostatic dusting of the frame, decorative hard chromium |

12 Pass Wire Drawing Machine

The wire drawing machine, also called wire passing machine, it is used for reducing wire sizes. This machine equipped with 12 pass which allows you to put 12 wire dies at a time. The capability for this machine is from maximum 1.2mm to minimum 0.1mm. It is a necessary machine for ewelry chain manufacturing plant. It is also used for other precious metal wires manufacturing purposes.

| Model No. | HS-1124 |

| Voltage | 380V 3 phase , 50/60Hz |

| Power | 3.5KW |

| Fastest Speed | 55 meters / minute |

| Capability | 1.2mm – 0.1mm |

| Cooling way | Automatic liquid cooling |

| Wire moulds | customized (sold separately) |

| Machine size | 1680*680*1280mm |

| Weight | Approx. 350kg |

Sheet Processing Equipment

10HP Sheet Rolling Mill

| MODEL NO. | HS-8HP | HS-10HP |

| Brand Name | HASUNG | |

| Voltage | 380V 50/60Hz, 3 phases | |

| Power | 5.5KW | 7.5KW |

| Roller | diameter 130/120 × width 248mm | diameter 150 × width 220mm |

| hardness | 60-61 ° | |

| Dimensions | 980×1180×1480mm | 1080x 580x1480mm |

| Weight | approx. 600kg | approx. 800kg |

| Capability | Maximum Rolling thickness is up 25mm | Maximum Rolling thickness is up to 35mm |

| Advantage | The frame is electrostatically dusted, the body is plated with decorative hard chrome, and the stainless steel cover is beautiful and practical without rust. single-speed / double speed | |

| After Warranty Service | Video technical support, Online support, Spare parts, Field maintenance and repair service | |

Tungsten Carbide Mirror Surface Sheet Rolling Mill

| Model No. | HS- M5HP | HS- M8HP | |||

| Brand Name | Hasung | ||||

| Voltage | 380V 3 phases; 50/60hz | ||||

| Power | 3.7kw | 3.7kw | 5.5kw | ||

| Tungsten Roller size | diameter 90 × width 60mm | diameter 90 × width 90mm | diameter 100 × width 100mm | diameter 120 × width 100mm | |

| hardness | 92-95 ° | ||||

| Material | imported tungsten steel billet | ||||

| Dimensions | 880×580× 1400mm | 880×580× 1400mm | 880×580× 1400mm | ||

| Weight | approx. 450kg | approx. 450kg | approx. 480kg | ||

| Feature | With lubrication, gear drive; Rolling sheet thickness 10mm, thinnest 0.1mm; extruded sheet metal surface mirror effect; static powder spraying on the frame, decorative hard chrome plating, stainless steel | ||||

The very abundant projects administration experiences and 1 to just one provider model make the higher importance of company communication and our easy understanding of your expectations for OEM Supply Manufacturing Gold Silver Continuous Copper Rod Casting Machine Equipment, We’ve professional goods knowledge and rich experience on manufacturing. We often imagine your achievements is our company!

OEM Supply China Gold Silver Continuous Casting Machine and Gold Silver Copper Rod Casting Machine, If you are for any reason unsure which product to select, do not hesitate to contact us and we will be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows “Survive by good quality, Develop by keeping good credit. ” operation policy. Welcome all the clients old and new to visit our company and talk about the business. We’ve been looking for more and more customers to create the glorious future.

Making strips, rods, sheets, pipes, etc.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

.png)