In today’s constantly developing materials science, the preparation technology of metal powders is crucial. Platinum water atomization pulverizer, as an advanced pulverization equipment, has shown broad application prospects in many industries due to its unique pulverization principle and advantages. This article will delve into which industries are suitable for using platinum water atomization powder mills.

1.Principle and advantages of platinum water atomization pulverizer

(1) Working principle

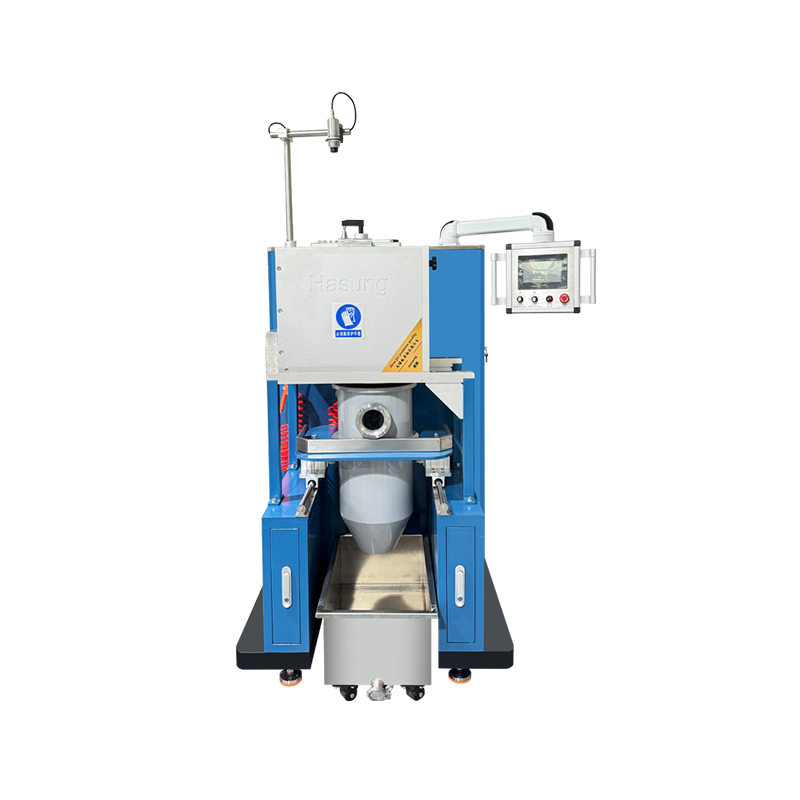

The platinum water atomization pulverizer shatters the molten metal flow through high-pressure water flow, causing it to atomize into small droplets. These droplets quickly cool and solidify during flight, forming metal powder. This powder making method can precisely control the particle size and shape of the powder.

(2) Advantages

Uniform particle size: The metal powder produced has a narrow particle size distribution, which can meet the industry’s high demand for powder quality.

Good sphericity: The powder is spherical in shape, with excellent flowability and filling properties, which is beneficial for subsequent molding and processing.

High purity: During the milling process, it can effectively reduce the mixing of impurities and ensure the high purity of the powder.

2.Suitable industries for use

(1) Electronic industry

①Manufacturing of electronic components

In the manufacturing of electronic components such as resistors, capacitors, inductors, high-precision metal powders are required. The powder produced by the platinum water atomization pulverizer has uniform particle size and good sphericity, which can ensure the stable performance of electronic components. For example, in the production of chip resistors, the use of this powder can improve the accuracy and stability of the resistor, and reduce the deviation of the resistance value.

②Semiconductor packaging

Semiconductor packaging requires highly reliable metal connection materials. The metal powder prepared by platinum water atomization powder machine can be used to manufacture high-performance solder and bonding wires. Its high-purity characteristics can effectively avoid introducing impurities during the semiconductor packaging process, reduce the risk of chip failure, and improve the yield of semiconductor devices.

(2)Aerospace industry

①Aircraft engine manufacturing

The components of aircraft engines need to have high strength, high temperature resistance, corrosion resistance and other properties. The high-temperature alloy powder produced by the platinum water atomization pulverizer can be used to manufacture key components such as turbine blades and combustion chambers for aircraft engines. By using powder metallurgy technology, the internal structure of components made from these powders is more uniform, and their performance is superior to those made by traditional casting and forging processes, which can effectively improve the efficiency and reliability of aircraft engines.

②Manufacturing of Aircraft Structural Components

For structural components of aircraft, such as fuselage frames, wings, etc., the use of powder metallurgy technology combined with platinum water atomization pulverizer to produce metal powder can achieve lightweight design of components. At the same time, structural components manufactured by powder metallurgy have better mechanical properties and can meet the requirements of aircraft use in complex working conditions.

(3)Medical industry

①Medical device manufacturing

In the field of medical device manufacturing, there are extremely high requirements for the biocompatibility and precision of materials. The metal powder produced by the platinum water atomization pulverizer can be used to manufacture medical devices such as artificial joints and dental implants. Its uniform particle size and high purity can ensure the surface quality and mechanical properties of medical devices, improve the compatibility between medical devices and human tissues, and reduce adverse reactions after implantation.

②Drug carrier

Metal powders have important applications as drug carriers in drug delivery systems. The powder produced by the platinum water atomization pulverizer can be loaded with drug molecules through surface modification techniques to achieve targeted delivery and sustained release of drugs. Its good sphericity and adjustable particle size are beneficial for the dispersion and transportation of drug carriers in the body, improving the efficacy of drugs.

(4) Automotive industry

①Automotive engine components

Some key components in car engines, such as valves and pistons, need to have good wear resistance and high temperature resistance. The metal powder produced by the platinum water atomization pulverizer and the engine components manufactured through powder metallurgy technology can improve the density and strength of the components, reduce wear, and extend the service life of the engine.

②Lightweight components for automobiles

With the pursuit of lightweight in the automotive industry, the application of powder metallurgy technology in the manufacturing of lightweight automotive components is becoming increasingly widespread. The aluminum alloy and magnesium alloy powders produced by platinum water atomization pulverizer can be used to manufacture car wheels, body structural components, etc. These lightweight components not only reduce the weight of the car, improve fuel economy, but also reduce exhaust emissions.

3.Conclusion

Platinum water atomization pulverizer, with its unique advantages, has important application value in multiple industries such as electronics, aerospace, medical, and automotive. With the continuous development of materials science and manufacturing, it is believed that platinum water atomization powder mills will be applied in more fields, providing strong support for technological progress and product upgrades in various industries. When selecting milling equipment, various industries should fully consider their own needs and the characteristics of platinum water atomization milling machines to achieve the best production efficiency and economic benefits.

Post time: Feb-26-2025