Gold Refining Machines: Those essential machines in the gold refining process

Gold has been a symbol of wealth and prosperity for centuries, and its value has made it a sought-after commodity across all walks of life. The gold refining process is crucial to ensure its purity and quality, and gold refineries play a vital role in this regard. In order to carry out the complex gold refining process, multiple machines are needed to ensure the efficiency and accuracy of the refining process. In this article, we will introduce the basic equipment required in a gold refinery, including gold flake making machines, gold powder atomizers, gold refining systems, gold smelting furnaces, metal granulator, and gold bar vacuum casting, logo stamping machine, etc.

Gold flakes making machine:

The first step in the gold refining process is to obtain gold in its raw form, usually in the form of gold ore or gold nuggets. In order to begin the refining process, gold needs to be broken down into thin flakes, more manageable pieces. This is where the sequin maker comes into play. and it’s easy for chemical soaking purpose. The machine is designed to melt and get raw gold material into thin gold alloy flakes, forming gold flakes that can then be further processed in a refining system.

Gold powder atomizer:

Apart from gold flakes, the other option is to convert raw materials into gold powders. The gold powder atomizer is the key equipment in this process, it is responsible for converting the gold alloy materials into powder (usually 100 mesh size) through the atomization process. This involves ejecting molten gold into a chamber where it solidifies into tiny particles, producing high-quality gold powder that is vital to the subsequent refining stage.

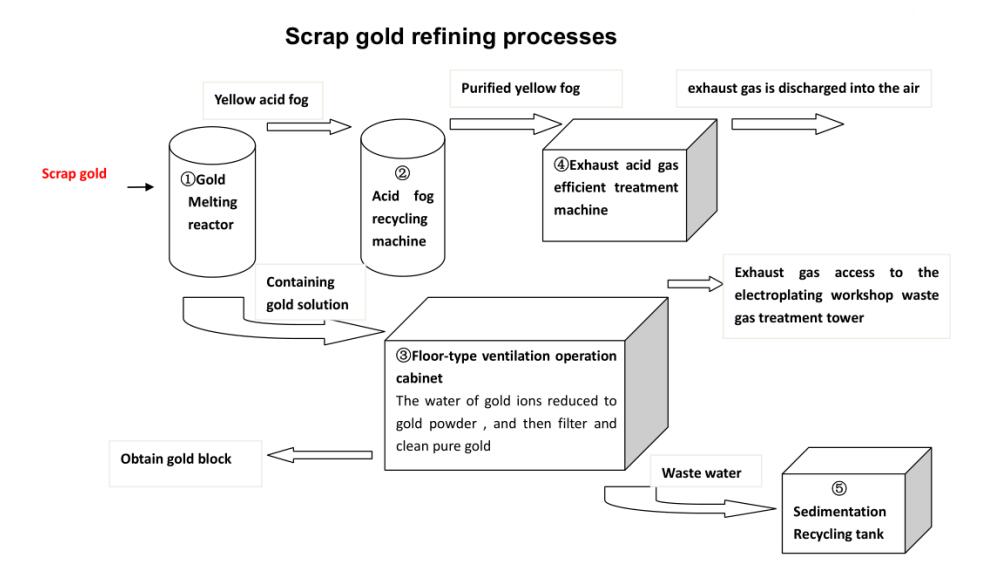

Gold refining system:

At the heart of any gold refinery is the gold refining system, which is responsible for purifying the gold and removing any impurities or contaminants. The system typically consists of various components, including chemical tanks, filters, and sedimentation devices, all of which work together to separate pure gold from other metals and impurities. Refining systems utilize chemical processes such as aqua regia or electrolysis to achieve the required gold purity, ensuring it meets industry standards for commercial use. Usually the production line cost depends on the capacity per day request, the system will be designed and equipped with requested capacity. This gold refining system mainly includes chemical reaction system, separation system, sewage water treatment system, duct and smoke treatment systems, etc.

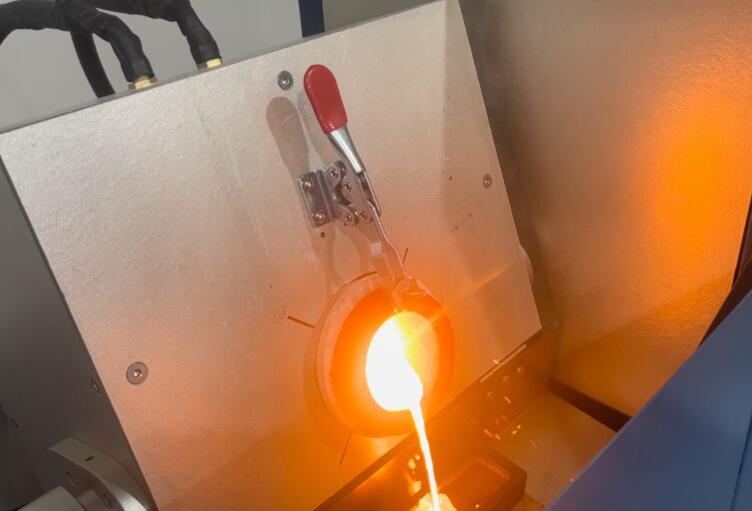

Gold melting furnace:

In order to further process the sponge gold from gold refining, the sponge gold must be melted into a molten state. This is where the golden furnace comes into play. The furnace is designed to heat the gold to its melting point, making it easy to handle and separate from any remaining impurities. The molten gold can then be poured into molds to create gold bars or other forms required for commercial purposes.

Metal granulating machine:

In order to get uniform gold shots which is easy and accurate meassured by weigning scales and final accurate weight of gold bars purposes, metal granulator is the key point machine to act the role. Melt the gold and get gold grains from granulating machine. It has two types while one is gravity granulating machine, the other is vacuum granulator.

Gold bar vacuum casting:

After gold is refined and melted as gold shots, it is often cast into specific shapes or forms to make it easier to handle and transport. A gold bar vacuum casting machine is used to achieve this as it accurately casts molten gold into a mold under vacuum conditions. This process ensures that the gold bars are formed with high precision and quality, ready for the market deals.

Logo stamping hydraulic press machine:

Usually gold dealers would like to make their own logo and name on gold bars, so logo stamping machine makes brilliant job on this. With different sizes of bars and differerent dies.

Dot peen marking system:

A gold bar is usually with its own serial number such as ID number, so usually gold makers use dot peen marking system to engrave serial numbers on every single gold ingot.

In summary, a gold refinery requires a series of specialized machines to perform the complex gold refining process. From breaking the raw gold material into flakes, to converting it into fine powder, and finally purifying and casting it into the desired shape, each machine plays a vital role in ensuring the quality and purity of refined gold. By investing in the right machinery and equipment, gold refineries can streamline operations and produce high-quality gold products that meet market demand.

You can contact Hasung for all of these equipment for your gold business. You’ll get the best machines with original manufacturer with good prices and services.

Post time: May-21-2024