In the field of jewelry processing, technological innovation and application have always been key forces driving industry development. Precious metal rolling mills, as equipment with high-precision processing capabilities, are gradually emerging in jewelry processing. This article will delve into the application prospects of precious metal rolling mills in jewelry processing, comprehensively analyzing their working principles, advantages, specific application scenarios, and future challenges and opportunities.

1.Working principle of precious metal rolling mill

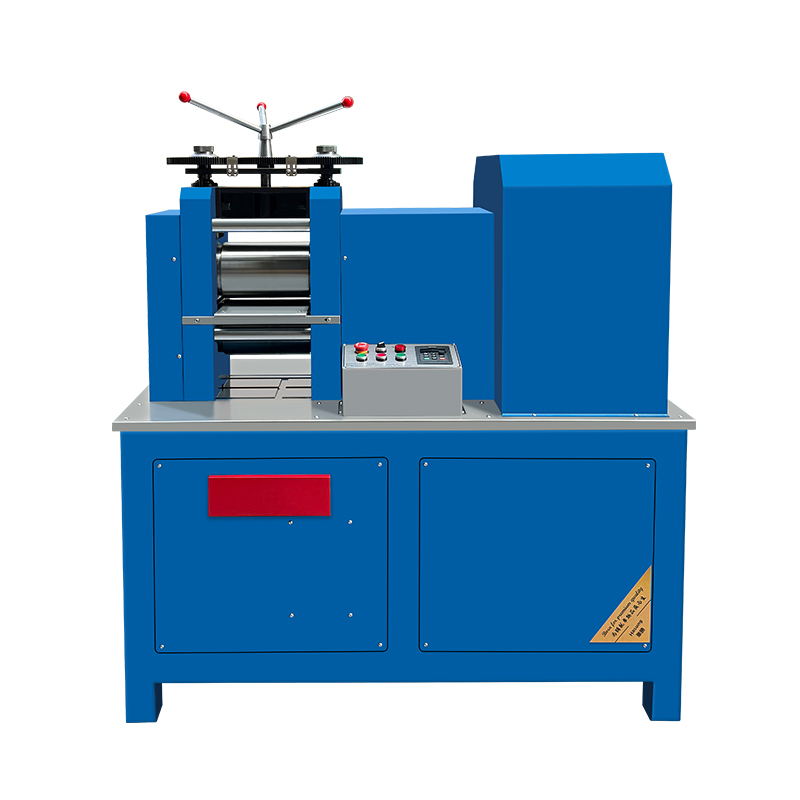

The precious metal rolling mill mainly applies pressure to the precious metal material placed between two rolls that rotate in opposite directions, causing it to undergo plastic deformation under the action of rolling force, thereby changing the thickness, width, and shape of the material. During the rolling process, high-precision processing of precious metal sheets or wires can be achieved by precisely controlling parameters such as roll speed, spacing, and rolling speed. For example, when rolling sheet metal, by gradually reducing the spacing between the rollers, the thickness of the sheet metal is uniformly reduced while maintaining the flatness and smoothness of the sheet metal surface. This precise control ability provides a foundation for the fine shaping of precious metal materials in jewelry processing.

2.The advantages of precious metal rolling mill in jewelry processing

① High precision processing: Jewelry processing requires extremely high precision, and precious metal rolling mills can achieve micrometer level thickness control and dimensional accuracy. Taking the production of ultra-thin precious metal sheets for jewelry inlay as an example, a rolling mill can roll precious metal sheets to extremely thin thicknesses with minimal thickness deviation, ensuring that each sheet can perfectly meet the requirements of jewelry design. This high-precision processing helps to improve the overall quality and delicacy of jewelry.

② Improve production efficiency: Compared to traditional manual forging or other processing methods, rolling mills can quickly process a large amount of precious metal materials. For example, when mass producing a certain specification of precious metal wire, the rolling mill can continuously roll, greatly shortening the production cycle. At the same time, the automation level of the rolling mill is relatively high, reducing manual operation links, not only reducing labor costs, but also ensuring the stability of product quality and improving production efficiency.

③ Rich material expression forms: Precious metals can be processed into various shapes and textures through rolling mills. For example, rolling plates with special patterns to create unique jewelry surface effects; Or roll out wires with different cross-sectional shapes to provide more creative space for jewelry design. This enables jewelry designers to break through the limitations of traditional material forms and create more innovative and personalized jewelry works.

3.Application scenarios of precious metal rolling mills in jewelry processing

① Preparation of jewelry inlay materials: In the jewelry inlay process, various shapes and specifications of precious metal sheets, wires, etc. are required as the basic materials for inlay. The precious metal rolling mill can accurately roll thin sheets that meet the requirements for making embedded brackets. For example, after rolling the gold plate to the appropriate thickness, exquisite claw inlaid brackets can be made through subsequent processes such as cutting and shaping, which can better fix gemstones and enhance the beauty and stability of jewelry.

② Surface texture treatment of jewelry: In order to increase the visual appeal and uniqueness of jewelry, it is often necessary to create various textures on its surface. The rolling mill can produce different texture effects such as wire drawing, sanding, and grid on the surface of precious metals through specially designed rollers. For example, rolling a delicate brushed texture on the surface of a silver pendant gives it a more textured and layered feel, enhancing the artistic value of the product.

③ Complex shaped jewelry production: For some jewelry with complex shapes, such as three-dimensional flower shapes, abstract geometric shapes, etc., the rolling mill can first roll the precious metal into suitable plates or wires, providing the basic material for subsequent shaping. Then, by combining with casting, forging and other processes, complex jewelry shapes can be more accurately shaped. For example, gold is first rolled into a specific thickness of sheet metal, then three-dimensional flower shapes are made through casting processes, and finally decorated with wire rolled by a rolling mill to make the jewelry shape more vivid and exquisite.

4.Challenges faced by the application of precious metal rolling mills

①The cost of equipment is relatively high: high-quality precious metal rolling mills are relatively expensive, and for some small jewelry processing enterprises or studios, the investment in purchasing equipment is relatively large. This may limit the rapid popularization of rolling mills in some jewelry processing fields. For example, a high-precision small precious metal rolling mill may cost hundreds of thousands of yuan or even more, which is a significant burden for some entrepreneurs with limited funds.

② High professional operation requirements: Operating a precious metal rolling mill requires professional technical knowledge and skills. Operators not only need to be familiar with the working principle and operation process of the rolling mill, but also need to be able to accurately adjust the various parameters of the rolling mill according to different precious metal materials and processing requirements. Otherwise, it may result in substandard product quality and even damage to the equipment. However, there are relatively few talents in the market with professional rolling mill operation skills, which to some extent affects the widespread application of rolling mills.

③ Difficulty in integrating with traditional craftsmanship: The jewelry processing industry has a long history, and traditional craftsmanship occupies an important position in the industry. Combining modern equipment such as precious metal rolling mills with traditional jewelry processing techniques requires enterprises and craftsmen to spend time and energy exploring and practicing. For example, in some traditional hand carved jewelry crafts that incorporate materials processed by rolling mills, it is necessary to find suitable bonding points to ensure that the charm of traditional craftsmanship is retained while also leveraging the advantages of rolling mills, which puts high demands on process innovation.

5.Opportunities for the application of precious metal rolling mills

① The demand for personalized customization is growing: With the continuous increase in consumers’ demand for personalized jewelry, jewelry processing enterprises need to have stronger innovation capabilities and production flexibility. Precious metal rolling mills can quickly and accurately produce various unique material forms to meet personalized customization needs. For example, consumers can customize precious metal jewelry with special textures or shapes according to their preferences, and the rolling mill can efficiently meet these design requirements, opening up a broader market space for jewelry processing enterprises.

② Technological development drives equipment upgrades: With the continuous advancement of technology, the performance of precious metal rolling mills is also constantly improving. For example, new rolling mills may adopt more advanced automation control systems to further improve machining accuracy and production efficiency; Meanwhile, the development of materials science may also encourage rolling mills to adopt roll materials and lubrication technologies that are more suitable for precious metal processing, reducing equipment wear and improving product quality. These technological upgrades will further enhance the application advantages of rolling mills in jewelry processing.

③ Strengthening industry cooperation and talent cultivation: In order to address the challenges of insufficient professional operators and process integration, the jewelry processing industry can strengthen cooperation between enterprises, universities, and training institutions. On the one hand, by offering relevant professional courses in colleges and universities, more professional talents with rolling mill operation skills and comprehensive knowledge of jewelry processing can be cultivated; On the other hand, enterprises can engage in technical exchanges and cooperation, jointly exploring the integration methods of rolling mills and traditional processes, and promoting the development of the entire industry.

In summary, precious metal rolling mills have broad application prospects in jewelry processing. Despite facing challenges such as high equipment costs, high professional operation requirements, and difficulty in integrating with traditional processes, these challenges are expected to be gradually resolved with the growth of personalized customization needs, the promotion of technology, and the strengthening of industry cooperation. The precious metal rolling mill will bring more innovative opportunities to the jewelry processing industry, promoting the development of the jewelry industry towards finer, more personalized, and more efficient directions. I believe that in the future, precious metal rolling mills will play an increasingly important role in the field of jewelry processing, helping the jewelry industry create more exquisite and unparalleled works.

Post time: Jan-19-2025