Introducing Gold Refinery Metal Powder Water Atomizer

Gold refining is a meticulous process that requires precision and efficiency to produce high-quality gold products. A key aspect of this process is the use of metal powder water atomizers, which play a vital role in the production of fine gold powder and other gold products. In this product introduction, we will explore the importance of metal powder water atomizers in gold refineries and how they contribute to the overall refining process.

Hasung Metal powder water atomizers are specially designed equipment designed to produce fine metal powders by atomizing molten metal using high-pressure water jets. In gold refineries, these atomizers are used to create gold powder, a basic material for a variety of applications, including jewelry manufacturing, electronics manufacturing, and investment casting.

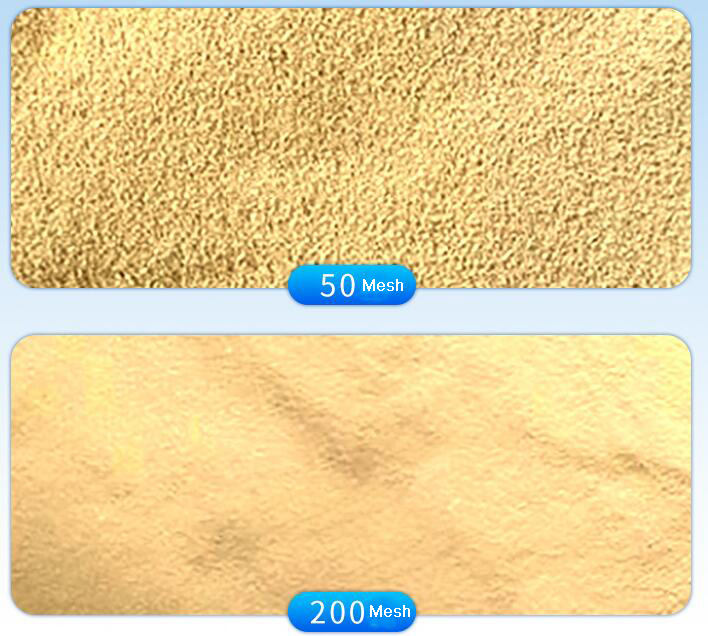

The process of producing gold powder using a metal powder water atomizer involves several key steps. First, high-purity gold is melted into a liquid state in a controlled environment. The molten gold is then atomized by water jets, forming fine gold particles that are rapidly cooled and solidified. The resulting gold powder has a uniform particle size distribution and high purity, making it suitable for a wide range of industrial and commercial uses.

One of the main advantages of using metal powder water atomizers in gold refineries is the ability to produce gold powder with exceptional purity and consistency. The atomization process ensures that the resulting powder is free of impurities and contaminants, meeting the stringent quality standards required for gold refining applications. Additionally, the controlled particle size distribution of the gold powder enables precise mixing and alloying, allowing the creation of customized gold alloys based on specific manufacturing requirements.

Additionally, metal powder water atomizers can significantly increase the efficiency of the gold refining process. By utilizing atomization technology, gold refineries can achieve higher yields and minimize material waste compared to traditional refining methods. The rapid solidification of atomized gold particles also helps improve material properties, such as enhanced flow and sintering behavior, which are critical for downstream processing and manufacturing operations.

In addition to their role in gold powder production, metal powder water atomizers are also integral to creating gold-based feedstock for additive manufacturing processes such as 3D printing. The ability to produce fine atomized gold particles enables the development of advanced additive manufacturing materials with customized properties, opening up new opportunities for the utilization of gold in cutting-edge industrial applications.

The versatility of metal powder water atomizers extends beyond gold refining, as these systems can be adapted to produce other precious and non-ferrous metal powders, including silver, platinum, copper and more. This flexibility allows gold refiners to leverage the capabilities of atomization technology to diversify their products and explore new market opportunities.

When considering implementing a metal powder water atomizer in a gold refining operation, it is essential to work with a reputable supplier that can provide advanced atomization systems suited to the specific requirements of the gold industry. Key considerations when selecting a metal powder water atomizer include the system’s capacity, atomization efficiency, energy consumption and overall reliability. Additionally, the supplier’s expertise in process optimization and technical support plays a vital role in ensuring seamless integration and operations within the gold refining facility.

To sum up, the metal powder water atomizer is an indispensable tool for gold refining, capable of producing high-quality gold powder and raw materials efficiently and accurately. By leveraging the capabilities of atomization technology, gold refiners can enhance their refining processes, achieve superior product quality, and take advantage of new opportunities in the evolving industrial and additive manufacturing sectors. As demand for high-purity gold products continues to grow across industries, the role of metal powder water atomizers in gold refineries remains critical in shaping the future of gold production and utilization.

Post time: Aug-19-2024