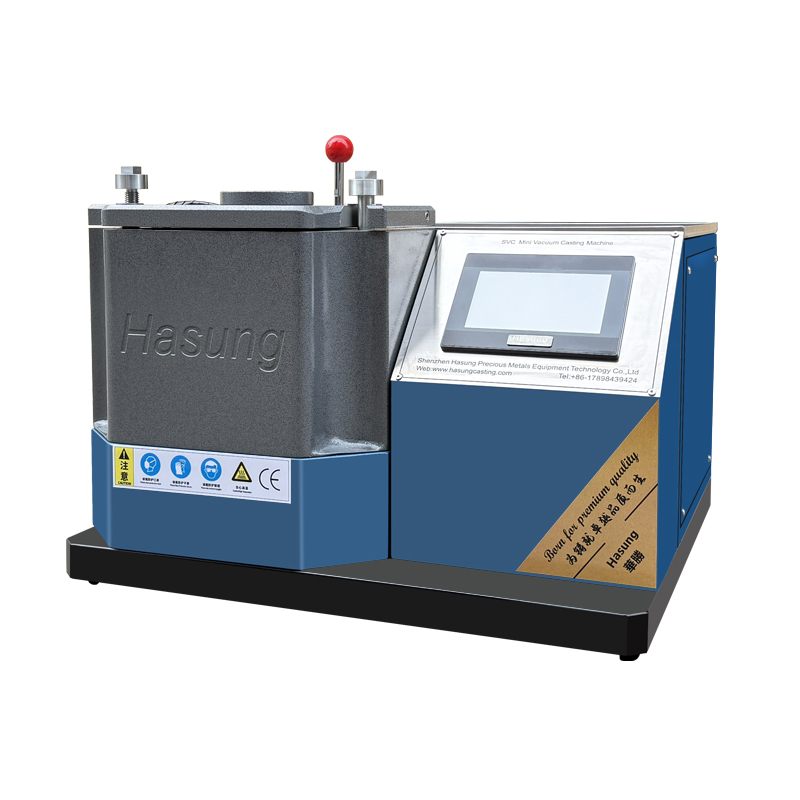

In the jewelry industry, the level of craftsmanship and innovation directly determine the quality and market competitiveness of products. As an advanced casting equipment, small vacuum casting machines are gradually emerging and bringing many innovations to jewelry production. With its unique working principle and performance characteristics, it has demonstrated significant advantages in improving the quality of jewelry castings, reducing production costs, and meeting personalized customization needs.

1.Brief Introduction to the Working Principle of Small Vacuum Casting Machine

A small vacuum casting machine performs casting operations by creating a vacuum environment in a closed mold cavity. Before the casting process begins, the mold is first placed in a vacuum chamber, and the exhaust system is quickly activated to extract air from the mold cavity, creating a low-pressure environment. When the metal liquid is injected into the mold cavity, due to the decrease in external pressure, the fluidity of the metal liquid is greatly improved, allowing for smoother filling of every tiny corner of the mold cavity. At the same time, the vacuum environment effectively reduces the contact between the molten metal and air, reduces the occurrence of oxidation and aspiration phenomena, and lays the foundation for obtaining high-quality castings.

2.Significantly improve the quality of jewelry castings

(1) Reduce pores and sand holes

In traditional casting methods, molten metal is prone to air entrainment during injection into the mold cavity, forming pores, and impurities in the molding sand may also lead to the formation of sand holes. The vacuum environment of small vacuum casting machines greatly reduces the presence of air, allowing the metal liquid to fill the mold cavity in a nearly airless state, significantly reducing the occurrence of pores and sand holes. For jewelry products that require extremely high surface quality, reducing these defects means presenting a smoother and more perfect surface, enhancing the overall quality and visual effect of the jewelry.

(2) Improve the density and strength of castings

In a vacuum environment, the shrinkage of molten metal is more uniform during solidification, and the internal structure is denser. This increases the density of jewelry castings and correspondingly enhances their strength. For example, when making complex shaped necklaces, pendants, or bracelets, higher density and strength can ensure that the product is not easily deformed or damaged during daily wear, prolong the service life of jewelry, and enhance consumers’ confidence in product quality.

3.Effectively reduce production costs

(1) Improvement of material utilization rate

A small vacuum casting machine can make the metal liquid fill the mold cavity more accurately, reducing waste caused by insufficient or excessive filling of the metal liquid. Compared to traditional casting methods, it has a higher utilization rate of materials. In jewelry production, the cost of precious metal materials is high, and improving material utilization directly reduces raw material costs. Taking gold as an example, every reduction in unnecessary losses can save considerable costs in large-scale production.

(2) Shorten production cycle

Due to the good fluidity of the metal liquid during vacuum casting, rapid filling of the mold cavity, and high casting quality, the workload of subsequent processes such as polishing and repair is greatly reduced. This shortens the entire jewelry production cycle. In a fast-paced market environment, a shorter production cycle means being able to push products to the market faster, meet consumer demand, reduce inventory backlog costs, and improve the efficiency of enterprise capital turnover.

4.Highly compatible with personalized customization needs

(1) Easy implementation of complex shapes

The trend of personalized customization in the jewelry industry is becoming increasingly evident, and consumers’ demand for unique shapes is constantly increasing. Small vacuum casting machines can cope with various complex designs, whether it is exquisite carvings, slender chains, or three-dimensional shapes, they can accurately replicate the shape of the mold through the good fluidity of the metal liquid in the vacuum environment, presenting the designer’s creativity perfectly. This provides strong support for jewelers to explore the personalized customization market.

(2) Rapid mold replacement and production adjustment

The small vacuum casting machine has flexible operation and easy and fast mold replacement. When receiving different customized orders, it is possible to quickly replace molds, adjust casting parameters, and start new production. This rapid response capability enables jewelry companies to timely meet the diverse needs of customers and gain an advantage in the fiercely competitive market.

5.Outstanding environmental advantages

(1) Reduce harmful gas emissions

In the traditional casting process, metal liquid is prone to oxidation when in contact with air. In order to ensure the quality of castings, it is often necessary to add some chemicals, which can produce harmful gas emissions at high temperatures. Small vacuum casting machines are used for casting in a vacuum environment, which reduces oxidation and dependence on chemical additives, effectively reducing the emission of harmful gases. This is in line with current environmental protection concepts and helps jewelry companies establish a good social image.

(2) Reduce dust pollution

In the traditional sand casting and cleaning process, a large amount of dust is generated, which poses a threat to the working environment and the health of operators. The small vacuum casting machine uses relatively clean casting materials and processes, and operates in a closed vacuum chamber, greatly reducing the generation and diffusion of dust, improving the working environment, and ensuring the physical health of employees.

Conclusion

Small vacuum casting machines, with their advantages in improving casting quality, reducing costs, meeting personalized customization, and environmental protection, are profoundly changing the production pattern of the jewelry industry.

With the continuous advancement and improvement of technology, it is expected to further promote the development of the jewelry industry towards high quality, high efficiency, and sustainability in the future, becoming an indispensable and important equipment in the field of jewelry production.

Jewelry companies actively introduce and apply small vacuum casting machines, which will occupy a more advantageous position in the fierce market competition and create more exquisite and unique jewelry products.

Post time: Mar-20-2025