Title: Benefits of using vacuum continuous casting machines for precious metals

The use of vacuum continuous casters is becoming more and more common when producing high-quality precious metal products. These machines offer a range of benefits that make them ideal for manufacturers looking to achieve outstanding results. In this blog, we will explore the advantages of using precious metal vacuum casters and why they are a valuable investment for businesses in this industry.

1. Superior Purity and Quality

One of the main benefits of using a precious metal vacuum continuous casting machine is the superior purity and quality of the final product. The vacuum environment eliminates the risk of contamination and ensures the metal maintains its integrity throughout the casting process. This gives the product superior purity and quality, making it very popular in the market.

2. Enhance mechanical properties

Vacuum continuous casters are designed to produce metals with enhanced mechanical properties. A controlled casting environment produces products with greater strength, durability and wear resistance. This makes them suitable for a wide range of applications from jewelry making to industrial manufacturing.

3. Precise control and customization

Another advantage of using vacuum casters is the precise control and customization they offer. Manufacturers can fine-tune the casting process to achieve specific shapes, sizes and compositions, allowing greater flexibility in product design. This level of customization is invaluable in meeting the diverse needs of our customers and creating unique, high-value products.

4. Efficient production process

Vacuum continuous casters are known for their efficient production processes, enabling high output and minimal material waste. The continuous casting method enables a stable production process and reduces the time and resources required to manufacture the finished product. This efficiency means manufacturers can save costs and increase productivity.

5. Reduce oxidation and gas absorption

The vacuum environment within the continuous casting machine effectively reduces oxidation and gas absorption during the casting process. This is crucial to maintaining the integrity of precious metals, as oxidation and gaseous impurities can damage their quality. By minimizing these factors, vacuum casters ensure that the final product meets the highest purity and performance standards.

6. Environmental benefits

In addition to the advantages in terms of product quality, vacuum continuous casters also have environmental benefits. The controlled casting environment minimizes the release of harmful emissions and waste, making the production process more sustainable. This is in line with the growing demand for environmentally friendly manufacturing practices and can enhance the reputation of companies in the precious metals industry.

7. Consistent results

Consistency is key in the production of precious metal products, and vacuum continuous casters meet this requirement. The controlled conditions of the vacuum environment ensure that each casting cycle produces consistent results, minimizing variations in product quality. This reliability is critical to meeting strict industry standards and building customer trust.

8. Improve safety and working environment

The use of vacuum casters helps provide operators with a safer, more controlled working environment. The risk of exposure to hazardous materials and fumes is reduced, improving workplace safety, while the automated nature of the machine streamlines the casting process and reduces physical stress on workers. This creates a more comfortable and safer environment for manufacturing operations.

9. Versatility of Metal Types

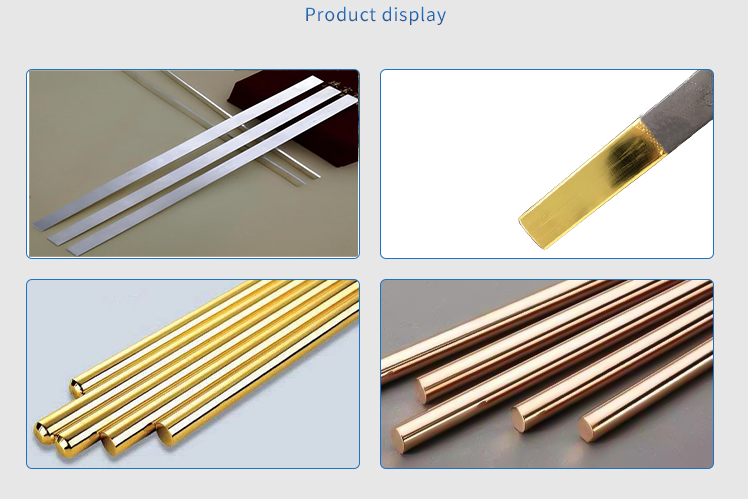

Vacuum continuous casting machines are capable of processing a variety of precious metals, including gold, silver, platinum and more. This versatility allows manufacturers to diversify their products and meet various market needs. Whether producing intricate jewelry or industrial components, these machines can easily adapt to different types of precious metals.

10. Long-term investment value

Ultimately, the use of vacuum continuous casters represents a long-term investment for companies in the precious metals industry. The combination of superior product quality, efficiency and environmental benefits make these machines valuable assets that can drive growth and profitability. By adopting this advanced casting technology, manufacturers can stay ahead of the competition and meet the changing needs of the market.

In summary, the benefits of using a vacuum continuous casting machine to cast precious metals are obvious and compelling. From ensuring excellent product quality to increasing efficiency and sustainability, these machines offer a range of benefits that make them an indispensable tool for manufacturers. As the demand for high-quality precious metal products continues to grow, investing in a vacuum continuous caster is a strategic decision that can bring significant returns to industry companies.

Post time: Jun-27-2024