In the world of metalworking, few tools are as important and versatile as the rolling mill. Especially in the field of precious metals, these machines play a vital role in shaping, refining and improving the quality of gold, silver, platinum and other materials. Whether you are an experienced jeweler, metal artist, or hobbyist, understanding the functions and benefits of a precious metal mill can take your craft to new heights.

What is a rolling mill?

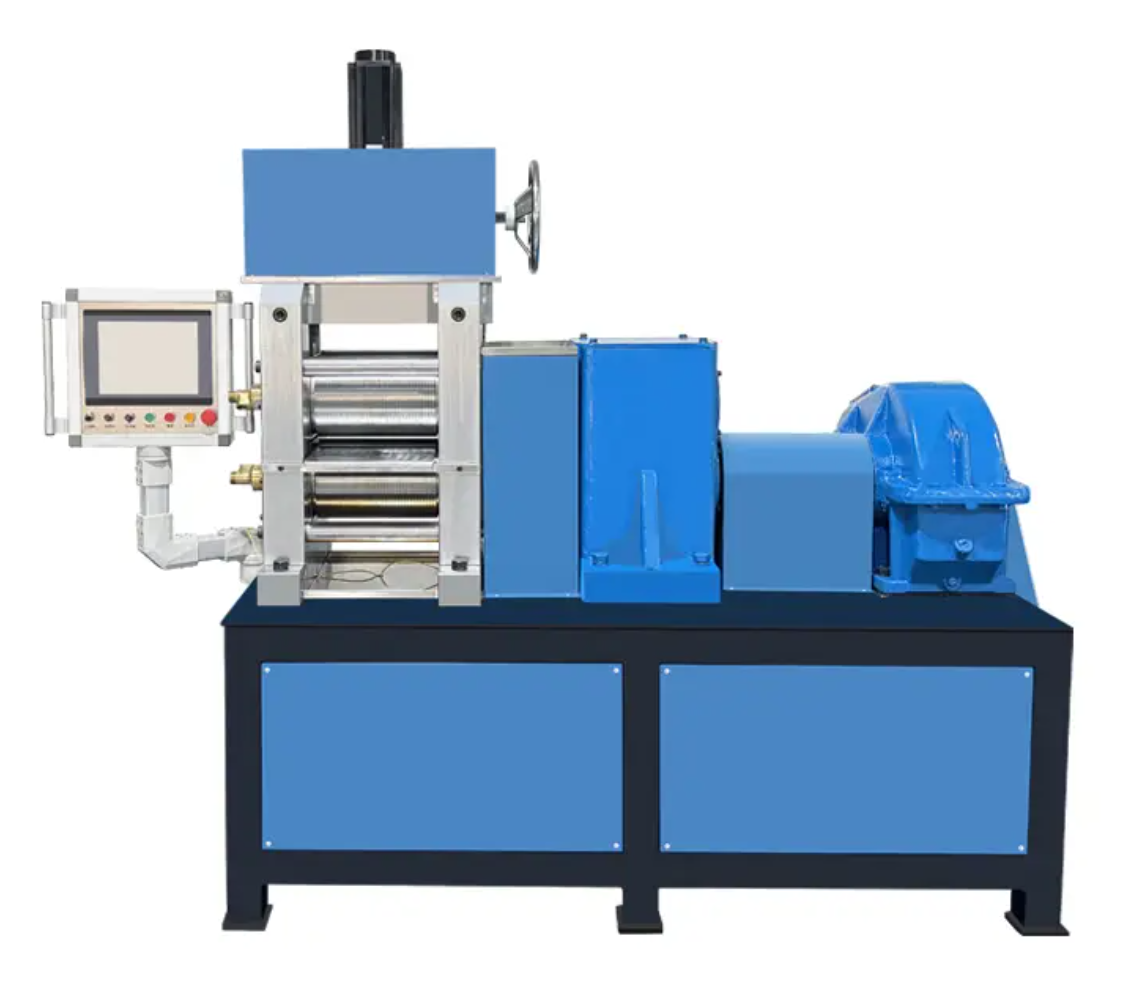

A rolling mill is a piece of equipment that processes metal by passing it through a pair of rollers. The main purpose of this machine is to reduce the thickness of the metal and create a uniform thickness throughout the sheet or wire. Rolling mills can be used on a variety of metals, but are especially valuable in precious metal processing due to their ductility and malleability.

Rolling mill type

There are many types of rolling mills, each designed for a specific application:

Flat rolling mill: used to produce metal flat sheets or plates. They are ideal for creating thin sheets of precious metals that can be used in jewelry making or other applications.

Wire Rod Mill: These mills are designed to produce wire rods of various diameters. They are vital for jewelers who need to create wire for rings, chains and other intricate designs.

Combination Rolling Mill: These versatile machines can perform flat rolling and wire rod rolling, making them a popular choice for small workshops and studios.

Electric Rolling Mill: These machines are powered by electricity and provide consistent speed and pressure, which is especially beneficial for mass production.

Benefits of using precious metal rolling mills

Accuracy and Consistency: One of the most significant advantages of using a rolling mill is the accuracy it provides. The machine can maintain a consistent thickness across the entire sheet or wire, which is critical to achieving high-quality results in jewelry making.

Material Savings: By using a rolling mill, jewelers can save precious metals. Instead of purchasing prefabricated sheets or wire, they can roll scrap metal or larger sheet metal into the desired thickness, minimizing waste.

VERSATILITY: Rolling mills can be used in a variety of applications, from creating complex designs to producing simple plate and wire. This versatility makes them a valuable tool for any metal worker.

Customization: Through the rolling mill, craftsmen can create customized thicknesses and shapes that are not easily available in the market. This ability to customize allows for greater creativity and innovation in design.

Improved workability: Rolling metal not only reduces its thickness but also improves its workability. The rolling process helps adjust the metal’s grain structure, making it easier to use in subsequent processes such as forging or welding.

How to choose the right rolling mill

When choosing a precious metal rolling mill, you need to consider the following factors:

Scale and Capacity: Consider the size of the projects you typically work on. If you are a hobbyist, a small hand grinder may be enough. However, if you have a larger operation, you may need an electric rolling mill with a higher capacity.

Material Compatibility: Make sure the rolling mill you choose is compatible with the type of precious metal you plan to use. Some grinders are designed for softer metals like gold and silver, while others can handle harder materials.

FEATURES AND ACCESSORIES: Look for additional features that can enhance your workflow, such as adjustable rollers, interchangeable dies, or built-in safety mechanisms. Accessories such as wire rollers or pattern rollers can also extend the capabilities of the machine.

Budget: Factory prices vary widely. Determine your budget and look for a machine that offers the best value for your needs without compromising on quality.

Rolling mill maintenance and upkeep

To ensure the longevity and optimal performance of your rolling mill, regular maintenance is essential. Here are some tips for keeping your machine in tip-top shape:

CLEAN AFTER USE: Always clean the drum and surrounding area after each use to prevent metal shavings and debris from building up.

Lubricate moving parts: Lubricate the moving parts of the machine regularly to reduce friction and wear.

Check for wear: Check the roller regularly for signs of wear. If you notice any damage, be sure to address it immediately to avoid further problems.

Correct Storage: When not in use, please keep the machine covered to prevent dust and moisture to avoid rust and corrosion.

In short

A precious metal rolling mill is an essential tool for anyone who works with metals, especially in the jewelry industry. Its ability to create precise, consistent and customized metal shapes makes it a favorite among craftsmen and manufacturers. By understanding the various types of milling machines, their benefits, and how to maintain them, you can improve your metalworking skills and produce stunning pieces that showcase the beauty of precious metals. Whether you are just starting out or want to upgrade your shop, investing in a quality rolling mill is a step towards process excellence.

Post time: Nov-07-2024