Metallurgy Russia is one of the exhibitions under Metallurgy, the largest metallurgical brand exhibition in the world. It has become an important business and trade platform in the Russian metallurgical and processing market.

Metallurgy Russia held relevant forums, seminars and roundtable meetings at the same time to integrate relevant manufacturers, distributors and end users. The exhibition has developed into a Russian metal week, providing a unique opportunity for all steel and professionals to learn about new technologies, new facility construction, new product releases, and marketing policies of peers

Our Booth Number:33M14

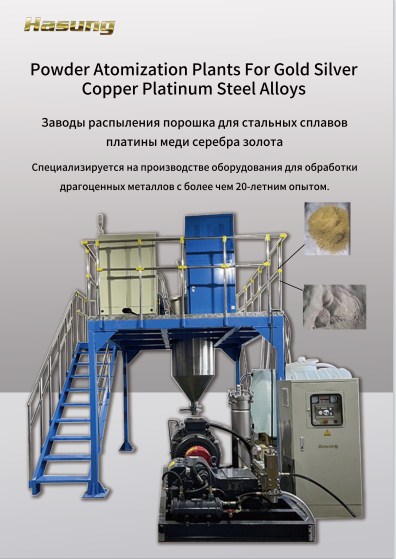

Featured products we will showcase at the exhibition:

Vacuum Ingot Casting Machines

Investors from all over the world earn lots of money by investing on gold, such as gold bullion deals, gold coins deals, gold minting deals, silver bullion, silver coins, etc. Vacuum Ingot Casting Machine is used for manufacturing a wide range of investment bullion bars of varying sizes and weights to ensure all individual customer requirements are met.

The development trend of atomization pulverization equipment in the future According to the survey data, the current demand for 3D printing technology is not concentrated on equipment, but is reflected in the variety of 3D printing consumables and the demand for agency processing services. Industrial customers are the main force in purchasing 3D printing equipment in my country. The equipment they purchase is mainly used in industries such as aviation, aerospace, electronic products, transportation, design, and cultural creativity.

Vacuum Induction Melting Furnace (VIM) FIM/FPt (Platinum, Palladium Rhodium And Alloys)

FIM/FPt is a vacuum furnace for melting platinum, palladium, rhodium, steel, and high temperature alloys with tilting mechanism.

It can be used to obtain a perfect melting of platinum and palladium alloys without any gas inclusions.

It can melt from a minimum of 500g to a maximum of 10kg of Platinum in minutes.

The melting unit is composed of a water-cooled stainless steel casing in which the case with crucible rotate and an ingot mold for tilting casting.

The melting, homogenization and casting phase can take place under vacuum or in a protective atmosphere.

Continuous Casting Machines

The function principle of ordinary type continuous casting machines is based on similar ideas as our vacuum pressure casting machines. Instead of filling the liquid material into a flask you can produce/draw sheet, wire, rod, or tube by using a graphite mold. All this happens without any air bubbles or shrinking porosity. The vacuum and high vacuum continuous casting machines are basically used for making high-end quality wires such as bonding wire, semiconductor, aerospace field

What is Wire Bonding?

Wire bonding is the method by which a length of small diameter soft metal wire is attached to a compatible metallic surface without the use of solder, flux, and in some cases with the use of heat above 150 degrees Celsius. Soft metals include Gold (Au), Copper (Cu), Silver (Ag), Aluminum (Al) and alloys such as Palladium-Silver (PdAg) and others.

Post time: May-19-2023