Mini Vacuum Pressure Casting Machine for Platinum Palladium Steel Gold Silver

Features

1. Intelligent jewellery vacuum pressure casting equipment Shenzhen Hasung Precious Metals Equipment Co. , Ltd is specially designed to produce precious metals casting and melting equipment with first class quality in China.

2. Using high-frequency heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving and environmental protection, and high work efficiency.

3. The closed type + vacuum/inert gas protection melting chamber can prevent the oxidation of molten raw materials and prevent the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or easily oxidized elemental metals.

4. Using a closed + vacuum/inert gas protection melting chamber, melting and vacuuming are performed at the same time, the time is halved, and the production efficiency is greatly improved.

5. Melting in an inert gas environment, the oxidation loss of the carbon crucible is almost negligible.

6. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color.

7. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

8. Using PID temperature control system, the temperature is more accurate (±1°C).

9. The HS-MC vacuum pressurized casting equipment is independently developed and manufactured with advanced technology and is dedicated to the melting and casting of platinum, palladium, stainless steel, gold, silver, copper and other alloys.

10. This equipment uses Mitsubishi PLC program control system, SMC pneumatic and Panasonic servo motor drive and other well-known brand components at home and abroad.

11. Melting, electromagnetic stirring, and refrigeration in a closed + vacuum/inert gas protection melting room, so that the product has the characteristics of no oxidation, low loss, no pores, no segregation in color, and beautiful appearance.

Hasung Vacuum Machine Compare To Other Companies

1. With dual-chamber, one for melting with positive pressure, one for casting with negative pressure and vacuum.

2. Larger capacity up to 350-500g maximum capacity for platinum.

3. Equipped with well-known Japan and German brands components.

4. Max. casting pressure up to 0.3Mpa.

Technical Parameters

| Model No. | HS-SVC |

| Voltage | 220V, 50/60Hz |

| Power Supply | 5KW |

| Max. Temperature | 2100°C |

| Temp Accuracy | ±1°C |

| Casting pressure | 0.1-0.3Mpa (adjust.) |

| Max. Capacity (Au/Pt) | 350g |

| Max. Flaks size | 3.15"x4" (80x102mm) |

| Application | Platinum, Palladium, Stainless steel, Gold, silver, copper and other alloys |

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system |

| Control System | Taiwan / Siemens PLC+Human-machine interface intelligent control system |

| Protective Gas | Nitrogen/Argon |

| Vacuum pump | Included |

| Cooling type | Running Water or Water chiller (Sold separately) |

| Dimensions | 560x450x680mm |

| Weight | approx. 70kg |

| Shipping Weight | approx. 120kg |

Product Display

Jewelry vacuum tilting pressure casting machine is customized to melt and cast jewelry for gold, platinum, silver, and other precious metal.

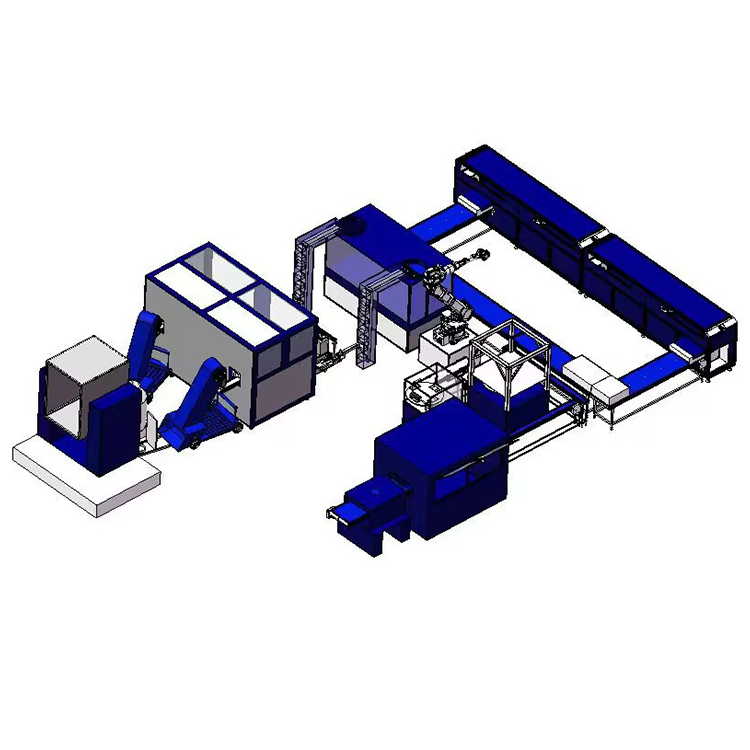

Hasung jewelry casting kit is designed of small quantities of jewelry casting, jewelry sample making, dental, and some precious metal DIY casting working at home purposes. The kit includes investment mixer, burnout oven, casting machine and sandblaster. It is hot sale as it fulfills many clients requests which max. capacity up to 500g.

It’s ideal to have a full casting line for a jeweler or small jewelry workshop.

The full casting line contains:

1. 3D printer

2. Rubber mold vulcanizer

3. Wax injector

4. Mini investment vacuum mixer

5. Burnout oven

6. Mini vacuum pressure casting machine

7. Cleaning system or sandblasting and polishing.

The other necessary tools are needed while making jewelry.

Jewelry casting kit (HS-MCK) is equipped with a gas chamber and casting chamber separately. The gas chamber that releases pressurized inert gas from melting chamber and vacuuming by casting chamber at the same time which completely eliminate any form of porosity and oxidation during the casting process. This feature that gives your final cast as a premium quality casting jewelries.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur