Manufacturing Companies for Vacuum Casting Machine Jewellery Jewelry Making - Mini Vacuum Pressure Casting Machine for Platinum Palladium Steel Gold Silver – Hasung

Manufacturing Companies for Vacuum Casting Machine Jewellery Jewelry Making - Mini Vacuum Pressure Casting Machine for Platinum Palladium Steel Gold Silver – Hasung Detail:

Features

1. Intelligent jewellery vacuum pressure casting equipment Shenzhen Hasung Precious Metals Equipment Co. , Ltd is specially designed to produce precious metals casting and melting equipment with first class quality in China.

2. Using high-frequency heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving and environmental protection, and high work efficiency.

3. The closed type + vacuum/inert gas protection melting chamber can prevent the oxidation of molten raw materials and prevent the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or easily oxidized elemental metals.

4. Using a closed + vacuum/inert gas protection melting chamber, melting and vacuuming are performed at the same time, the time is halved, and the production efficiency is greatly improved.

5. Melting in an inert gas environment, the oxidation loss of the carbon crucible is almost negligible.

6. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color.

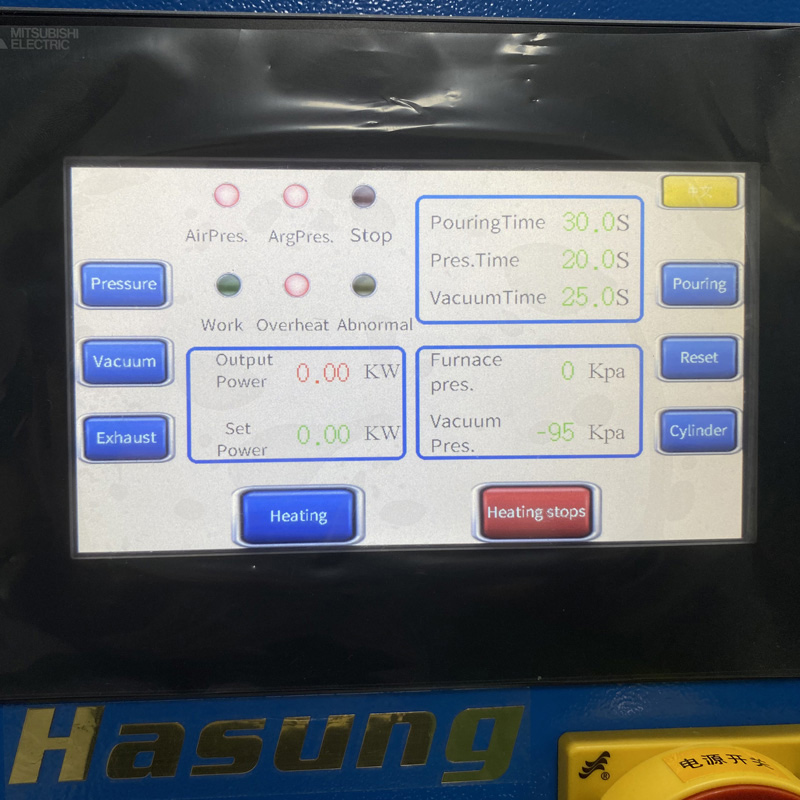

7. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

8. Using PID temperature control system, the temperature is more accurate (±1°C).

9. The HS-MC vacuum pressurized casting equipment is independently developed and manufactured with advanced technology and is dedicated to the melting and casting of platinum, palladium, stainless steel, gold, silver, copper and other alloys.

10. This equipment uses Mitsubishi PLC program control system, SMC pneumatic and Panasonic servo motor drive and other well-known brand components at home and abroad.

11. Melting, electromagnetic stirring, and refrigeration in a closed + vacuum/inert gas protection melting room, so that the product has the characteristics of no oxidation, low loss, no pores, no segregation in color, and beautiful appearance.

Hasung Vacuum Machine Compare To Other Companies

1. With dual-chamber, one for melting with positive pressure, one for casting with negative pressure and vacuum.

2. Larger capacity up to 400-500g maximum capacity for platinum.

3. Equipped with well-known Japan and German brands components.

4. Max. casting pressure up to 0.3Mpa.

Technical Parameters

| Model No. | HS-MC1 |

| Voltage | 220V, 50/60Hz |

| Power Supply | 5KW |

| Temp Accuracy | ±1°C |

| Casting pressure | 0.1-0.3Mpa (adjust.) |

| Max. Capacity (Au/Pt) | 500g |

| Max. Flaks size | 3.15″x3.15″ (80x80mm) |

| Application | Platinum, Palladium, Stainless steel, Gold, silver, copper and other alloys |

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system |

| Control System | Mitsubishi PLC+Human-machine interface intelligent control system |

| Protective Gas | Nitrogen/Argon |

| Vacuum pump | Included |

| Cooling type | Running Water or Water chiller (Sold separately) |

| Dimensions | 560x450x680mm |

| Weight | approx. 80kg |

| Shipping Weight | approx. 140kg |

Product Display

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our company continuously improves our product quality to meet the needs of customers and further focuses on safety, reliability, environmental requirements, and innovation of Manufacturing Companies for Vacuum Casting Machine Jewellery Jewelry Making - Mini Vacuum Pressure Casting Machine for Platinum Palladium Steel Gold Silver – Hasung , The product will supply to all over the world, such as: Canberra, Singapore, Ecuador, Make sure you genuinely feel free to send us your requirements and we are going to respond for you asap. We now have got a skilled engineering group to serve for your just about every detailed needs. Cost-free samples could be sent to suit your needs personally to understand much more information. In an effort to meet your requires, be sure to seriously feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd objects. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.