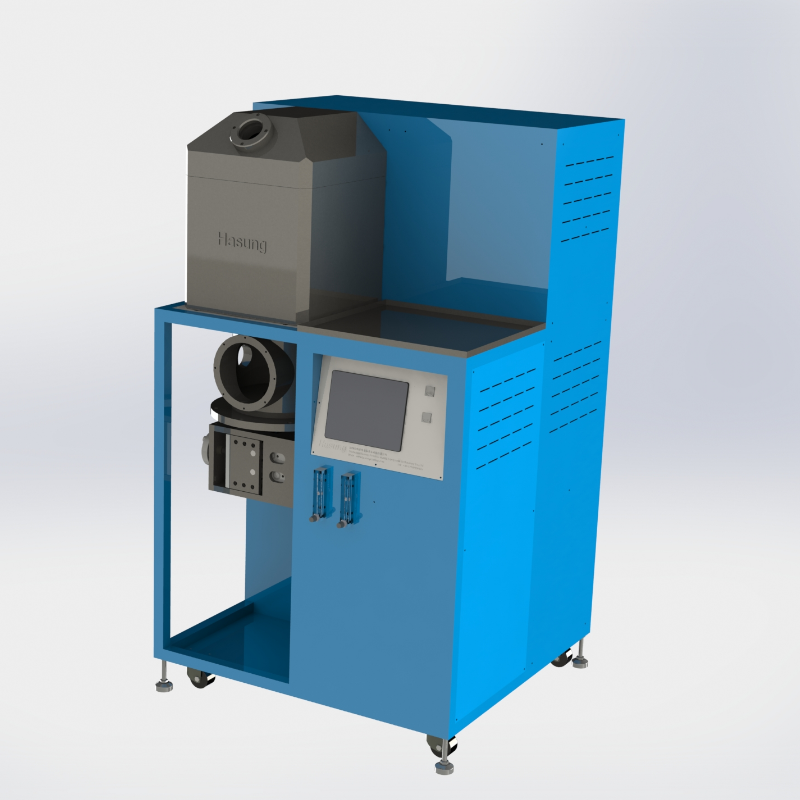

Short Description:

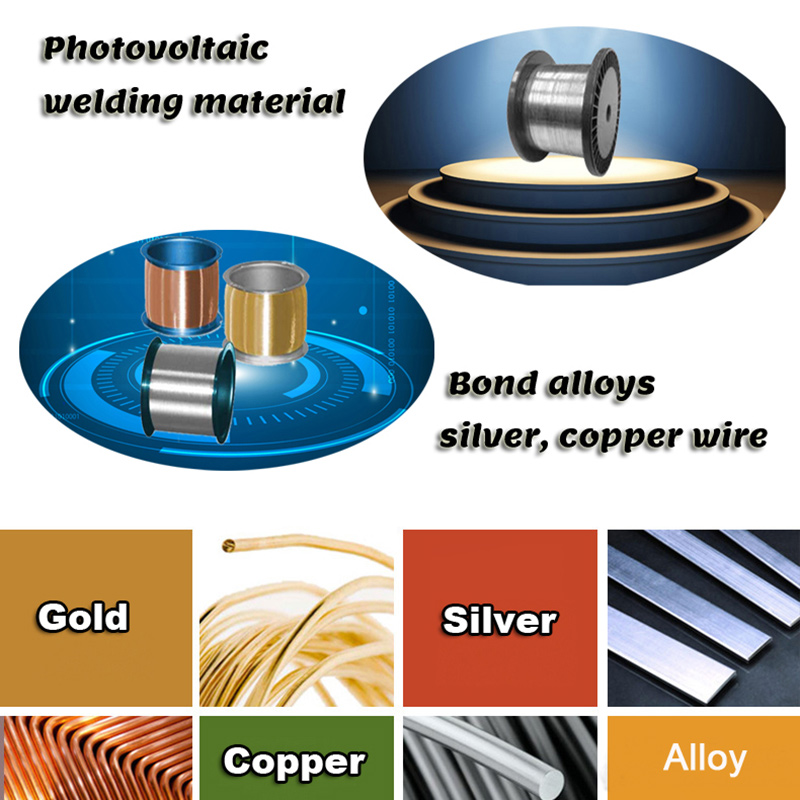

Casting of electronic materials such as bond alloy silver copper wire and high-purity special wire The design of this equipment system is based on the actual needs of the project and process, and makes full use of modern high-tech technology.

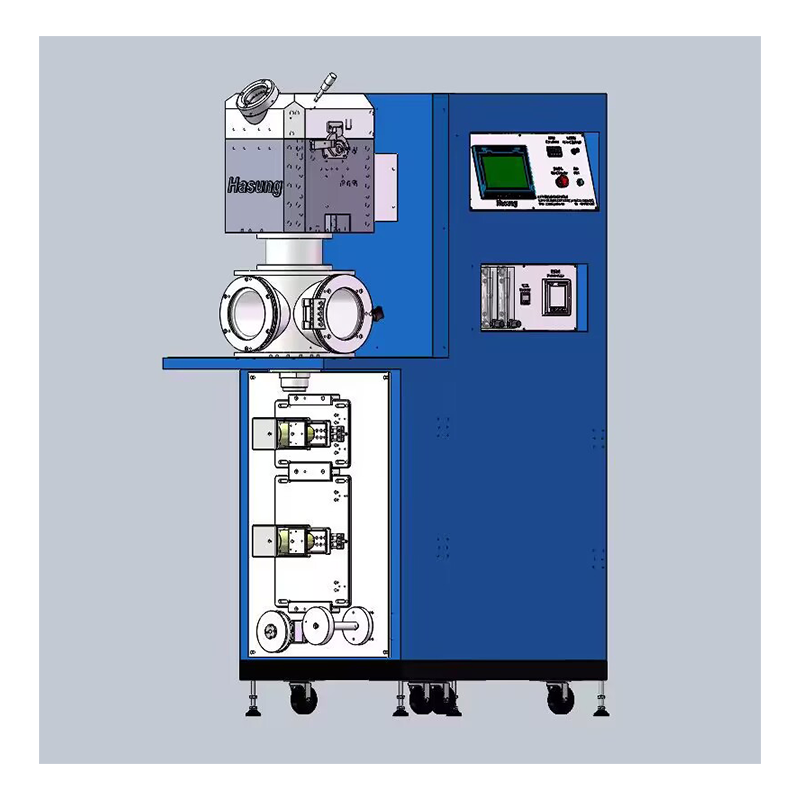

1. Adopt German high-frequency heating technology, automatic frequency tracking and multiple protection technology, which can melt in a short time, save energy and work efficiently.

2. The closed type + inert gas protection melting chamber can prevent the oxidation of molten raw materials and the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or easily oxidized elemental metals.

3. Use closed + inert gas to protect the melting chamber. When melting in an inert gas environment, the oxidation loss of the carbon mold is almost negligible.

4. With the function of electromagnetic stirring + mechanical stirring under the protection of inert gas, there is no segregation in color.

5. Using Mistake Proofing (anti-fool) automatic control system, the operation is more convenient.

6. Using PID temperature control system, the temperature is more accurate (±1°C).

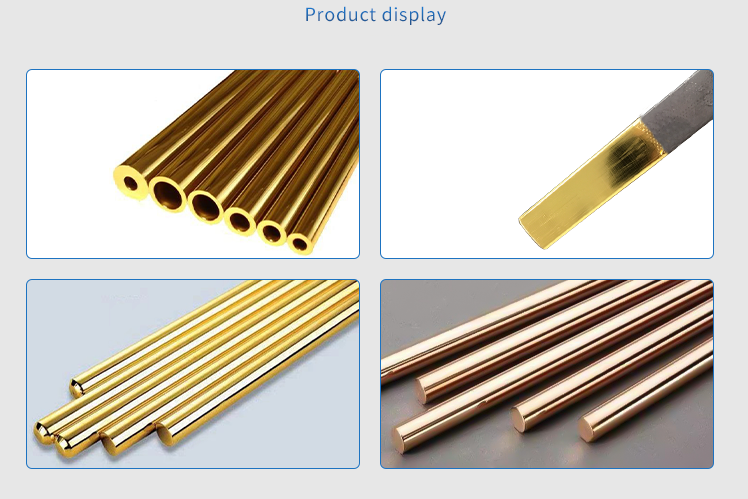

7. HVCC series high vacuum continuous casting equipment is independently developed and manufactured, with advanced technology, used for continuous casting of high purity gold, silver, copper and other alloys.

8. This equipment uses Mitsubishi PLC program control system, SMC pneumatic and Panasonic servo motor drive and other domestic and foreign brand components.

9. Melting in a closed + inert gas protection melting room, double feeding, electromagnetic stirring, mechanical stirring, refrigeration, so that the product has the characteristics of no oxidation, low loss, no porosity, no segregation in color, and beautiful appearance.

10. Vacuum Type: High vacuum.