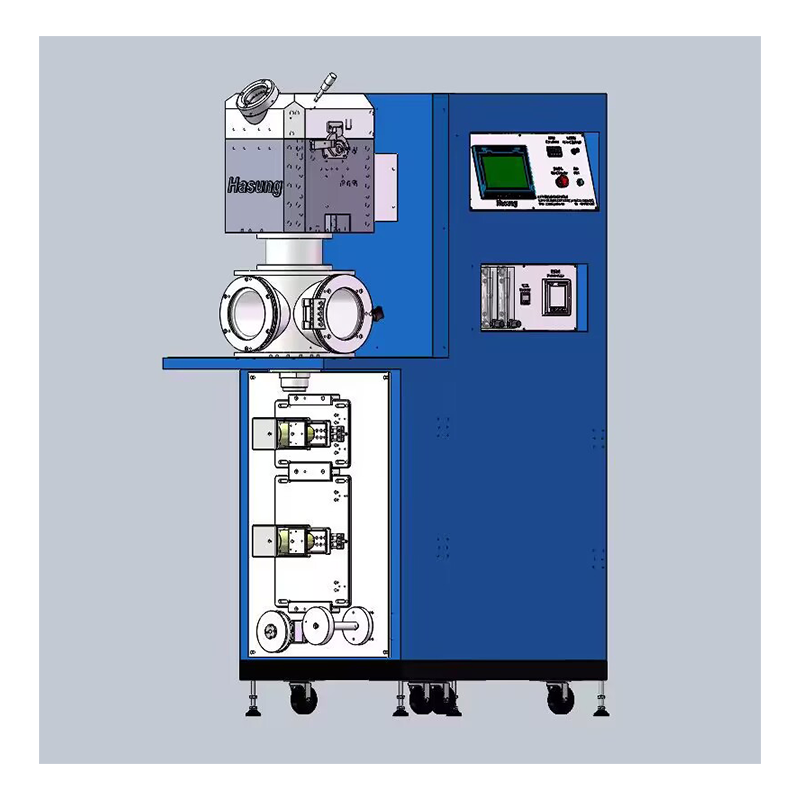

TVC Series Induction Vacuum Pressure Casting Machine for Gold Silver Copper

Why Do You Choose Hasung Vacuum Pressure Casting Machine?

Features

Hasung automatic vacuum Casting machines compare to other companies

TVC series casting machine is the most innovative in the latest generation of pressure vacuum casting machine in the world market. They use low-frequency generators, and the power control is proportional and is managed entirely by a computer. The operator simply puts the metal into the crucible, places the cylinder and presses the button! The "TVC" series model comes with a 7-inch color touch screen. Throughout the merger process, the operation is gradual.

Automatic process:

When press button of “Auto”, vacuum, inert gas, heating, strong magnetic mixing, vacuum, casting, , vacuum with pressure, cooling, all processes done by one key mode.

Regardless of the type and quantity of gold, silver, and alloy, the frequency and power are modulated. Once the molten metal reaches the casting temperature, the computer system adjusts the heating and emits a low-frequency pulses to sense the stirring alloy. When all set parameters are reached and the temperature stabilizes at the maximum deviation at ± 4°C, the casting starts automatically, followed by a strong pressurization of the metal with an inert gas.

TVC series casting machine is one of the most innovative in the latest generation of pressure vacuum casting machine in the world market.

They use low-frequency generators, and the power control is proportional and is managed entirely by a computer.

The operator simply puts the metal into the crucible, places the cylinder and presses the button! The

"TVC" series model comes with a 7-inch color touch screen.

Throughout the merger process, the operation is gradual.

Regardless of the type and quantity of gold, silver, and alloy, the frequency and power are modulated.

Once the molten metal reaches the casting temperature, the computer system adjusts the heating and emits a low-frequency pulses to sense the stirring alloy.

When all set parameters are reached and the temperature stabilizes at the maximum deviation at ± 4°C, the casting starts automatically, followed by a strong pressurization of the metal with an inert gas.

Technical Parameters

| Model No. | HS-TVC1 | HS-TVC2 | HS-TVC4 | HS-TVC6 | HS-TVC8 |

| Voltage | 220V single phase / 380V 3 phases 50/60Hz | 380V 3 phases, 50/60Hz | |||

| Power Supply | 10KW | 15KW | 20KW | ||

| Max Temp | 1500°C | ||||

| Melting Time | 2-3 min. | 3-5 min. | 3-5min | 3-5 min. | 4-6 min. |

| Shielding Gas | Argon / Nitrogen | ||||

| Pressure | 0.1-0.4Mpa, 1 - 4 bar (Adjustable) | ||||

| Temp Accuracy | ±1°C | ||||

| Capacity (Gold) | 1kg | 2kg | 4kg | 6kg | 8kg (Gold) |

| Max. Flask size | 4"x10" / 5"x12" | 5"x12"/6.3"x12" | 6.3"x12" | 8.6"x12" / 10"x13" | |

| Vacuum Pump | High quality vacuum pump/German vacuum pump, vacuum degree - 100KPA (optional) | ||||

| Application | Gold, K gold, silver, copper and other alloys | ||||

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | ||||

| Cooling type | Water chiller(sold separately) or Running water | ||||

| Dimensions | 680*880*1230mm | ||||

| Weight | approx. 130kg | approx. 140kg | approx. 160kg | approx. 180kg | approx. 250kg |

Product Display

Casting methods

The usual casting methods are:

flame casting

induction casting

vacuum pressure die-casting

Flame casting

Flame casting is the most traditional casting method and it is probably the most common and less expensive one. This method has been useful to develop casting techniques but it does not fit well with the legal and technical requirements of present-day market. This technique is based solely on the operator’s competence and skill: use of this technique requires ability to control the flame, a good knowledge of metalworking as well as sensitivity and operation carefulness.Although it is true that many operators are true masters of this technique we think that this technique will not guarantee reproducibility and a constant quality level. And if a process, such as this, is completely based on the operator’s skill and competence it is not a flexible process, and flexibility is an essential requirement for modern dental technician laboratories. The process should, indeed, be reproducible regardless of operators’ competence. In addition to this the flame casting method does not allow certification and documenting of the casting process by means of automatic process control systems.

Induction casting

Induction casting has surely represented a breakthrough in the casting sector but despite this the technique has some features that make it impossible to use it in a rational and organized way in the dental technician’s laboratory.The induction system is semi-automatic in nature and the whole process, like flame casting, depends on the operator’s skill.Is a fact that the operator has the task to evaluate whether melting has been correct and to activate the centrifugal device. «Therefore, reproducibility and constant quality level cannot be guaranteed using this technique.Induction casting is very quick. The metal alloy is heated from the inside to the outside. The technical nature of the induction system makes it impossible to stabilise the alloy temperature over time or to block the temperature increase.The centrifugal pressure is unidirectional and many induction casting machines do not feature a vacuum system, therefore the air found in the unit may cause a porous casting.

Vacuum pressure die-casting

The vacuum pressure die casting has always been considered a high-quality casting process, however its popularity remained limited until the mid-90s due to the fact that the temperatures reached by these devices were not suitable for melting and casting of the new dental alloys. A new generation of devices were later developped, that were capable of melting base-metal, semi-precious, Palladian and precious dental alloys.

The Hasung vacuum pressure die-casting machines feature an excellent melting temperature control, producing the casting in a vacuum and making it possible to carry out multi-directional pressure. All of this ensures great usage flexibility, reproducibility and constant quality and minimises the operator’s impact on the outcome.

How to achieve a good casting

Follow casting temperature requirements

Keeping control over casting temperature is the most important requirement to maintain the metallurgic features of the alloy. Compliance with the casting data and specifi cations is essential to avoid sublimation of the low melting point metals contained in the alloy.

A metal molten at the appropriate temperature will have all the features prescribed by the manufacturing company, otherwise there may be some changes in the metallurgic structure of the metal that may cause changes in technical properties and problems during the subsequent processing phases.

Casting with omnidirectional pressure

Dental alloys are composed of several different metals, each with its own specifi c density. By using centrifugal injection techniques the result will be a mono-directional pressure in which the metals with higher specifi c densities are introduced in the cylinder before the ones with lower densities. Using the pressure die-casting techniques, the metal is introduced statically in the cylinder and then the cylinder is exposed to an omni-directional and constant pressure that allows perfect layering of the metal.

Vacuum casting

To achieve high mechanical resistance and accuracy the casting shall be carried out in an airfree environment. This ensures a completely non porous alloy casting.

The advantages of the Hasung die-casting system

Compliance with set temperature specifi cations

This is possible thanks to a system that combines control by microprocessor, thermocouple and control logic, carried out with a complex electronic system featuring an infra-red pointer.

Advantages: Maximum accuracy in alloy production with subsequent preservation of metallurgic specifi cations.

Omnidirectional pressure on the metal

Automatic compression produces an uniform and even pressure on the whole cylinder. There is no centrifugal effect of the metals that compose the alloy.

Advantages: Higher alloy compactness, better layering, saving of alloy material (there is no need for extra material to be used for channels and excess cast material)

Melting is carried out in an atmospheric environment

But casting is carried out in an airless environment because the TVC series casting machines, before overturning, carry out a air free production automatic process.

Advantages: Maximum accuracy, high quality and time saving in finishing works.

Maximum operation flexibility

Usability by all laboratory components for there is no human intervention.

Advantages: Usability by all laboratory components.

Quality reproducibility

The process is automatic and features no human intervention.

Advantages: The automatic cycle and absence of human intervention grant a perfect reproducibility of results.

Cost effective management

Overall process management is 100% cost effective: electric energy consumption is low and the consumables are inexpensive.

Advantages: cost effectiveness.

Vacuum pressure casting machine consumables:

1. Graphite crucible

2. Ceramic gasket

3. Ceramic jacket

4. Graphite stopper

5. Thermocouple

6. Heating coil

The full jewellery production line includes:

1. 3D printer

2. Vulcanizer

3. Wax injector

4. Burnout oven

5. Vacuum pressure casting machine

6. Cleaning

7. Polishing

Nowadays, jewellery factories love to have full automatic casting systems which saves a lot of labour costs and increases production efficiency. At Hasung, we provide you full jewelry casting solutions at the highest quality products assured from China.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur