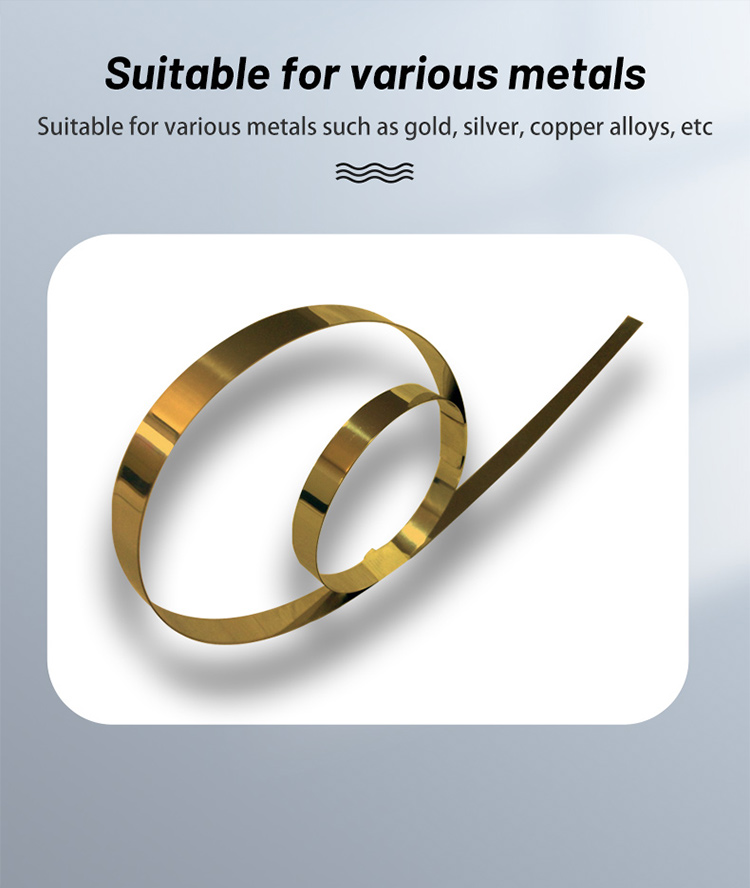

Hasung-Four Head Continuous Strip Rolling Mill for Precious Metal

Equipment advantages:

1. Durable rolling mill: Made of high hardness material DC53, ensuring longer service life and efficiency

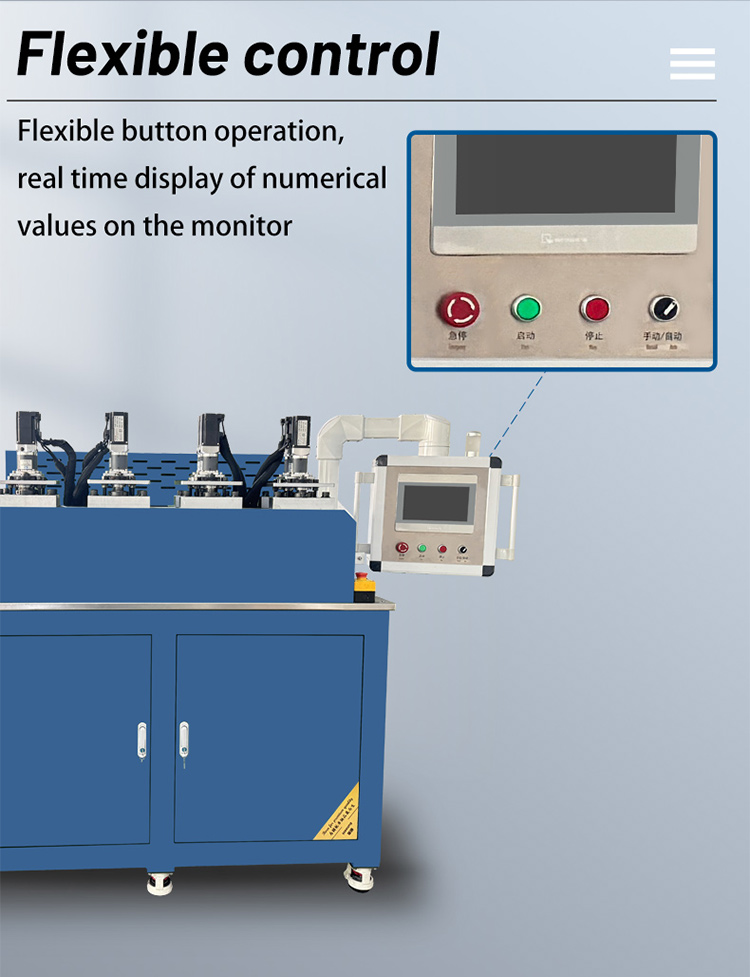

2. Intelligent control: The main rolling power is driven by servo motors and controlled by Siemens PLC and touch screen. Numerical control adjusts the height of the rolling mill, controls the thickness of the finished product, and calculates the speed of the main rolling servo motor

3. Save manpower: Simply put the material into the continuous rolling mill to produce the finished product Equipped with a shortage alarm function

4. Safety: The hazardous areas around the equipment are equipped with protective covers

5. High precision: The thickness tolerance of the finished product is controlled within plus or minus 0.01mm Strictly control the machining accuracy of components, exchange parts of the same model, and maintain them quickly

6. The PLC adopts Siemens brand 10 inch Weilun Tong touch screen.

7. The appearance design of the equipment is generous and appropriate, with sheet metal frames treated with baking paint, and parts treated with electroplating or blackening

8. The body is thick and the appearance design of the equipment is generous and appropriate, which increases the stability of the equipment during operation.

9. Strictly control the manufacturing accuracy of equipment parts, process mechanical components according to the drawing accuracy, and ensure interchangeability of the same model, making maintenance convenient, time-saving, and fast.

10. Add oil for lubrication, and use No. 3 butter for the roller bearings

11. The important component bearings are imported bearings from the German brand INA, ensuring high precision and durability

12. Simple and sturdy structure, small space occupation, low noise, and easy operation.

13. High compression accuracy, stainless steel oil pan for desktop anti oil and anti rust, no oil leakage

14. Equipped with emergency stop safety device Control panel, one inlet and one outlet, with a total of three emergency stop switches.

Equipment parameters:

Power supply: 380V, 50HZ 3-phase

Rolling mill power: 2.5KW x 4 sets

Adjust the power of the roller gap group: 200W X 4 groups

Roller size (D * L) 108 * 110mm

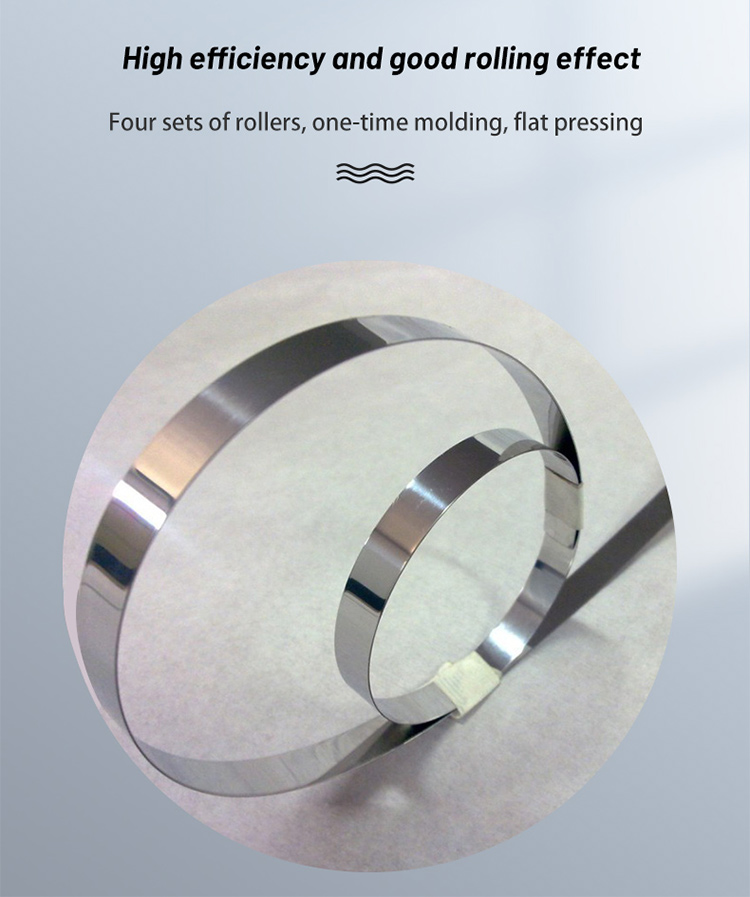

Number of roller groups: 4 groups

Roll material/smoothness: DC53/smooth Ra0.4 4 sets of mirror surfaces

Active force control method for tablet pressing: 4 sets of servo motors+Siemens PLC+10 inch Weilun Tong touch screen

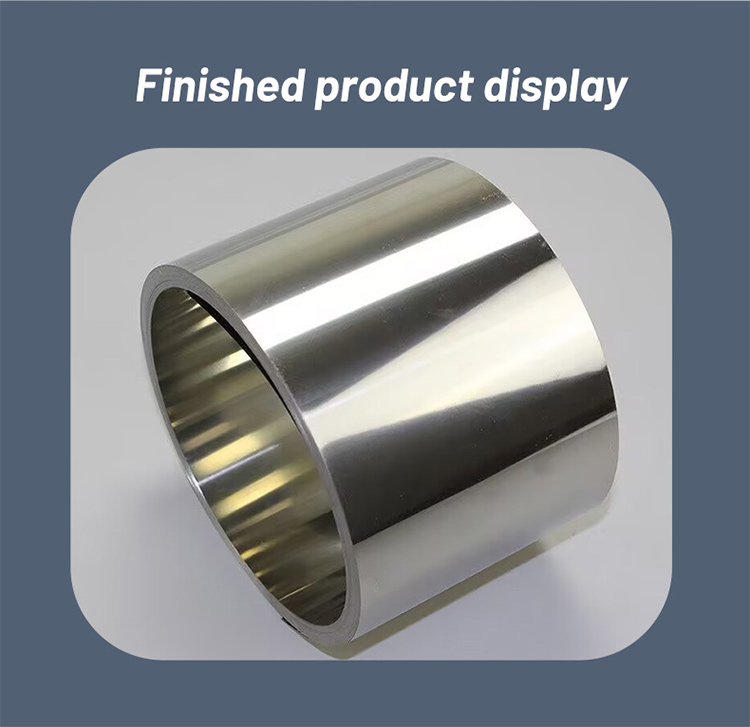

Maximum thickness: 8mm

Thinnest tablet thickness: 0.1mm (gold)

Finished product thickness tolerance: plus or minus 0.01mm

Best compression width: within 40mm

Servo adjustment roller gap accuracy: plus or minus 0.001mm

Pressing speed: 0-100 meters per minute (servo motor speed regulation)

Finished product measurement method: manual measurement

Bearing lubrication method: Solid grease

Lubrication method: automatic oil supply

Rolling mill dimensions: 1520 * 800 * 1630mm

Rolling mill weight: approximately 750KG

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur