Automatic Gold Bullion Vacuum Casting Machine 12KG 15KG 30KG

Features

1. Intelligent Vacuum Gold Bar Casting:

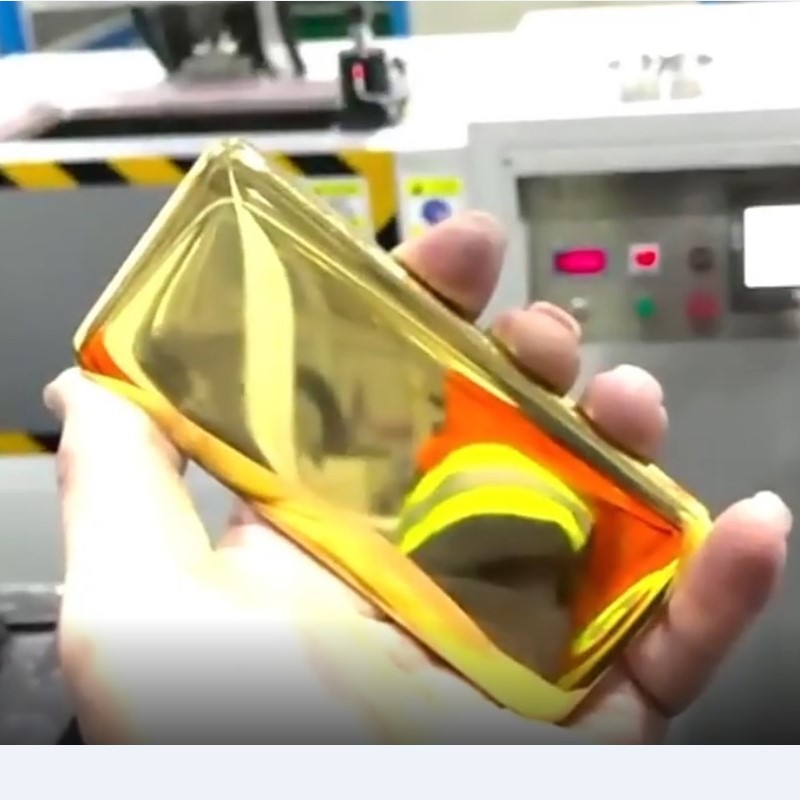

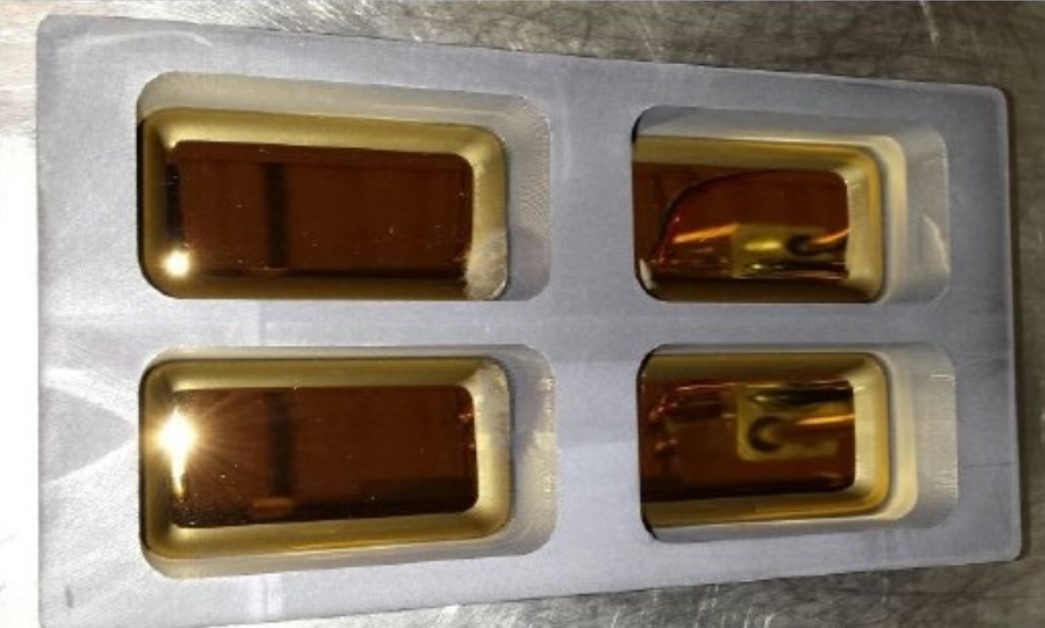

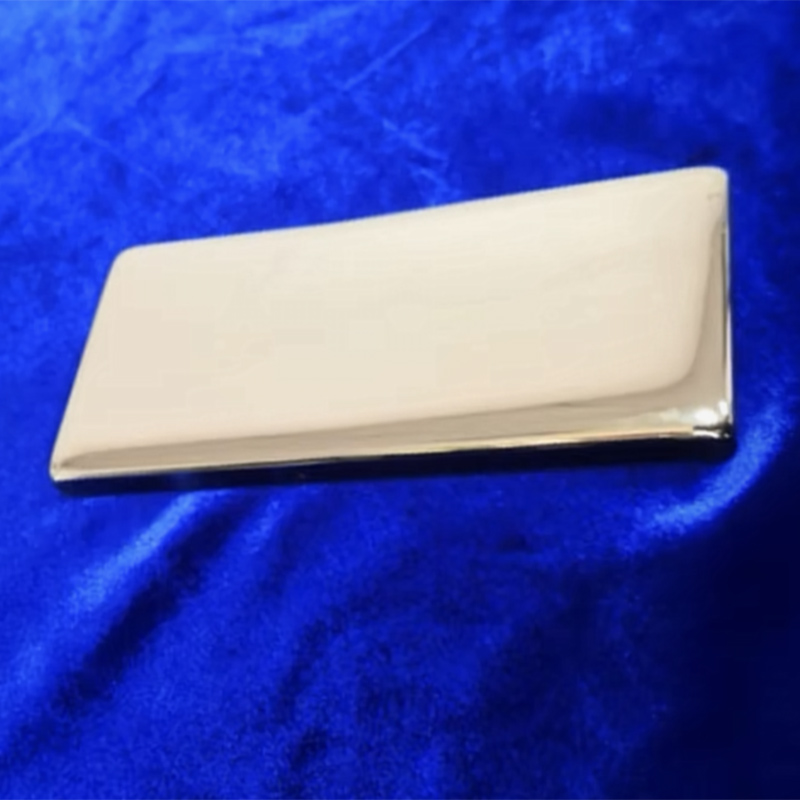

1).Presssing one key-- Automatic close the cover--Automatic casting and cooling--Automatic open the cover--

2).Take out the Shiny gold Bar

2.Operation method: One-key operation to complete the entire process, POKA YOKE foolproof system.

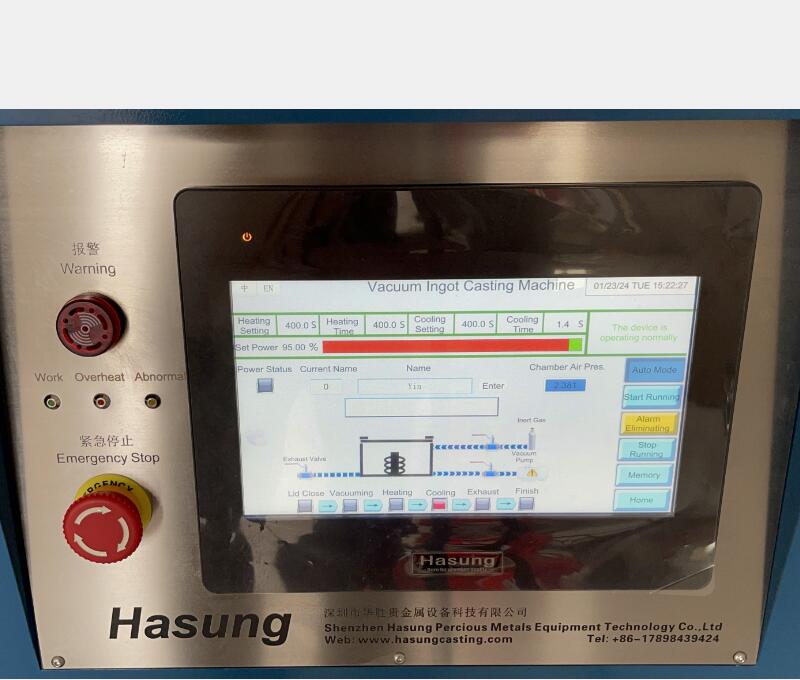

3. Control system:Mitsubishi PLC+Human-machine interface intelligent control system (optional).

4. Using German high-frequency heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving, and high work efficiency.

5. The closed type/channel type + vacuum/inert gas protection melting chamber can prevent the oxidation of molten raw materials and the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or elemental metals that are easily oxidized.

6. Adopt closed/channel type + vacuum/inert gas to protect the melting chamber, melting and cooling are performed at the same time, the time is halved and the production efficiency is increased.

7. Melting in an inert gas environment, the oxidation loss of the carbon mold is almost negligible.

8. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color.

9. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

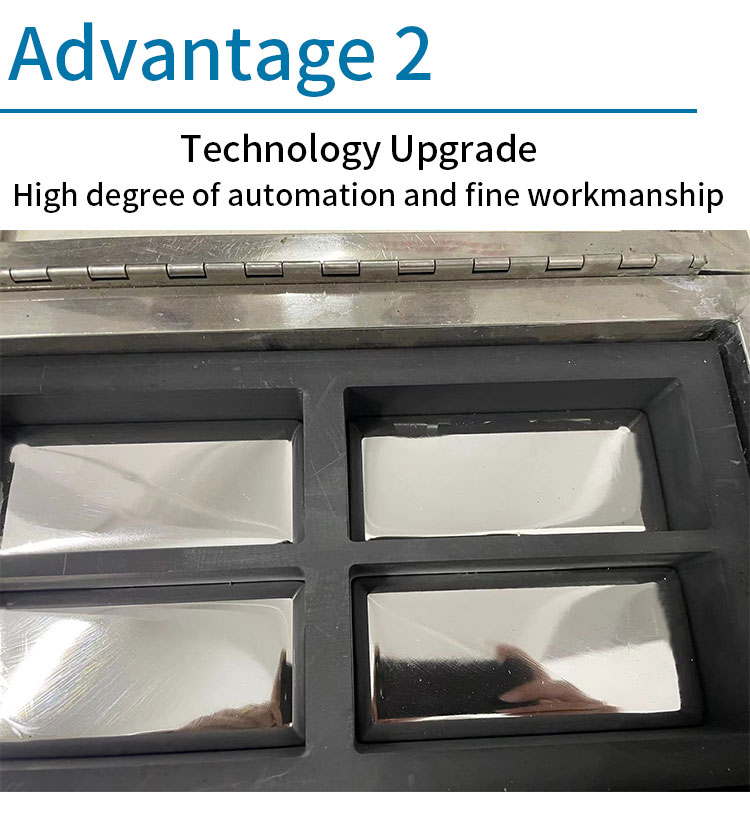

10. Using Weinview / Siemens PLC control system, air inlet is automatically controlled.

11. HS-GV4, HS-GV15 HS-GV30 gold and silver ingot forming equipment/full-automatic production line is independently developed and manufactured with advanced technical level products for the smelting and casting of gold, silver, copper and other alloys.

12. This casting equipment uses Weinview / Siemens PLC program control system, SMC/AirTec pneumatic and Panasonic servo motor drive and other domestic and foreign brand components.

13. Melting, electromagnetic stirring, and refrigeration in a closed/channel + vacuum/inert gas protection melting room, so that the product has the characteristics of no oxidation, low loss, no porosity, no segregation in color, and beautiful appearance.

Technical Parameters

| Model No. | HS-GV4 | HS-GV15 | HS-GV30 | ||

| Automatic Opening Cover Gold Bar Vacuum Casting Machine | |||||

| Power Supply | 380V ,50/60Hz | ||||

| Power Input | 50KW | 65KW | 80KW | ||

| Max Temp | 1500°C | ||||

| Overal Casting Time | 10-12mins. | 12-15mins. | 15-20mins. | ||

| Shielding Gas | Argon / Nitrogen | ||||

| Program for different bars | Available | ||||

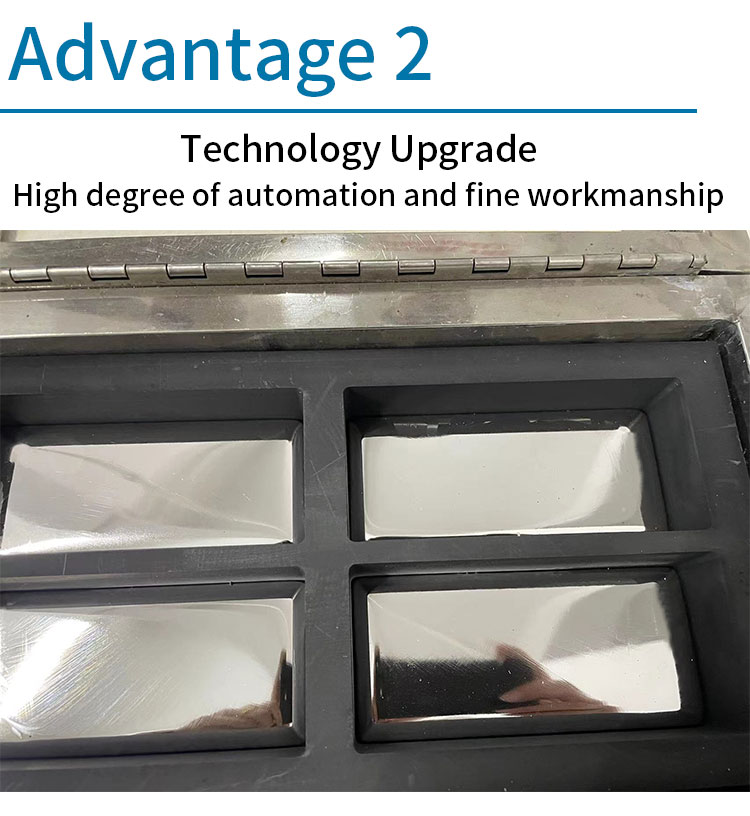

| Capacity | 4kg : 4 pcs 1kg, 8pcs 0.5kg or more. | 15kg : 1pcs 15kg, or 5pcs 2kg or more | 30kg : 1pcs 30kg, or 2pcs 15kg or more | ||

| Application | Gold,Silver,Platinum,Palladium (When by Pt, Pd, customized) | ||||

| Vacuum Pump | High quality vacuum pump/German Vacuum Pump, Vacuum degree-100KPA | ||||

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | ||||

| Control system | Weinview / Siemens PLC +Human-machine interface intelligent control system (optional) | ||||

| Cooling type | Water chiller(sold separately) or Running water | ||||

| Dimensions | 1150x680x1060mm | 1150x680x1060mm | 1250x680x1060mm | ||

| Weight | 350KG | 360KG | 400KG | ||

Product Display

.png)

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur