Featured Products

-

High reputation Medium Frequency Induction Gold Melting Machine (HS-MU)

The MU melting unit system is based on the actual needs of the jewelry melting and precious metals refining purpose.

1. HS-MU melting units are independently developed and manufactured with advanced technical level products for the smelting and casting of gold, silver, copper and other alloys.

2. HS-MUQ melting furnaces are equipped with single heating generator but dual use for the smelting and casting of platinum, palladium, stainless steel, gold, silver, copper and other alloys, which can be used by changing crucibles only. Easier and convenient.

-

New Arrival China Vertical Metal Smelting Furnace Induction Heating Machine Silver and Gold Melting Machine

The design of this tilting melting system is based on the actual needs of the project and process, using modern high-tech technology. Safety guarranted.

1. Adopt Germany IGBT heating technology, automatic frequency tracking and multiple protection technology, which can melt metals in a short time, save energy and work efficiently.

2. Using electromagnetic stirring function, no segregation in color.

3. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

4. Using PID temperature control system, the temperature is more accurate (±1°C) (optional).

5. The HS-TFQ smelting equipment is independently developed and manufactured with advanced technical level products for the smelting and casting of gold, silver, copper, etc.

The HS-TFQ series is designed for melting platinum, palladium, Rhodium, gold, silver, copper and other alloys.

6. This equipment apply many foreign famous brands components.

7. It keeps heating while pouring metal liquids at a great condition which enables users to get great quality casting.

-

.png)

China wholesale Small Metal High-Frequency Gold Melting Furnace Directly Supplied by The Manufacturer

The MU melting unit system is based on the actual needs of the jewelry melting and precious metals refining purpose.

1. HS-MU melting units are independently developed and manufactured with advanced technical level products for the smelting and casting of gold, silver, copper and other alloys.

2. HS-MUQ melting furnaces are equipped with single heating generator but dual use for the smelting and casting of platinum, palladium, stainless steel, gold, silver, copper and other alloys, which can be used by changing crucibles only. Easier and convenient.

-

.png)

12 Years Exporter Induction Gold Smelting Furnace Electric Smelting Furnace

The MU melting unit system is based on the actual needs of the jewelry melting and precious metals refining purpose.

1. HS-MU melting units are independently developed and manufactured with advanced technical level products for the smelting and casting of gold, silver, copper and other alloys.

2. HS-MUQ melting furnaces are equipped with single heating generator but dual use for the smelting and casting of platinum, palladium, stainless steel, gold, silver, copper and other alloys, which can be used by changing crucibles only. Easier and convenient.

-

Discountable price 5kg Capacity Induction Furnace for Melting Metal

The desktop mini induction melting furnace, capacity from 1kg-2kg, which takes 1-2 minutes to melt one batch of metal. It comes in a compact design and can be 24 hours continuously working. Also, this metal furnace is highly environmentally friendly, using 6KW power with 220V single phase which saves a lot of energy to deliver the desired results.

It’s highly recommended for small jewelry factory or jewelry workshop, efficient and long lifetime using. Though it’s small device, it fulfills a great job for users.

Temperature control device is optional for this machine.

-

2019 China New Design Dt-Jd4 1600º C Electromagnetic Induction Heating a Four-Piece Vacuum Ingot Casting Machine

Why do You Choose Hasung vacuum Gold Bar Casting Machine ?

Hasung Vacuum Ingot Casting machines (HS-GV2) is designed for casting 2kg quality silver and gold bullions. This casting machine comes with the flexibility on moulds to customize your silver and gold bars, ingots and bullions with any of your designs and sizes.

The inert gas chamber of this gold silver bar casting machine ensures that you have a final casting with premium quality and mirror appearance by completely eliminating all forms of porosity, water waves or shrinkage in your final pieces.

Comparing with the traditional method. Your whole casting process will be done under vacuum and inert gas. Thereby giving your casting products a brilliant quality. With the above features your operators is fully guaranteed to operate our equipment easily.

Hasung’s original components are from well-known domestic and world famous brands like Japan AirTec, Taiwan Weinview, and German Siemens, Schneider, Omron, etc.

-

Wholesale Price Metal Smelting Furnace Induction Heating Machine Silver and Gold Melting Machine Hot Sell

The design of this tilting melting system is based on the actual needs of the project and process, using modern high-tech technology. Safety guarranted.

1. Adopt German high-frequency heating technology, automatic frequency tracking and multiple protection technology, which can melt metals in a short time, save energy and work efficiently.

2. Using electromagnetic stirring function, no segregation in color.

3. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

4. Using PID temperature control system, the temperature is more accurate (±1°C) (optional).

5. The HS-TFQ smelting equipment is independently developed and manufactured with advanced technical level products for the smelting and casting of gold, silver, copper, etc.

The HS-TFQ series is designed for melting platinum, palladium, Rhodium, gold, silver, copper and other alloys.

6. This equipment apply many foreign famous brands components.

7. It keeps heating while pouring metal liquids at a great condition which enables users to get great quality casting.

-

Wholesale Price China Vacuum Induction Heating Melting Furnace

FIM/FPt is a vacuum furnace for melting platinum, palladium, rhodium, steel, and high temperature alloys with tilting mechanism.

It can be used to obtain a perfect melting of platinum and palladium alloys without any gas inclusions.

It can melt from a minimum of 500g to a maximum of 10kg of Platinum in minutes.

The melting unit is composed of a water-cooled stainless steel casing in which the case with crucible rotate and an ingot mold for tilting casting.

The melting, homogenization and casting phase can take place under vacuum or in a protective atmosphere.

The furnace is complete with:

- Double stage rotary vane vacuum pump in oil bath;

- High precision digital pressure sensor;

- Optical pyrometer for temperature control;

- High precision digital vacuum switch for vacuum reading + Display.

Advantages

- Vacuum melting technology

- Manual/Automatic tilting system

- High melting temperature

Hasung Technology High Temperature Vacuum Induction Melting Furnace Experimental Vacuum Melting Furnace

Product Features

1. Fast melting speed, the temperature can reach above 2200℃

2. With mechanical stirring function, the material is stirred more evenly

3. Equipped with programmed temperature control, set the heating or cooling curve according to your process requirements, the equipment will automatically heat or cool according to this process

4. With a pouring device, the molten sample can be poured into the prepared ingot mold, and the shape of the sample you want can be poured

5. It can be smelted under various atmosphere conditions: smelting in air, protective atmosphere and high vacuum conditions, buy one kind of equipment, realize various functions; save your cost to a certain extent.

6. With secondary feeding system: It can realize adding other elements during the melting process, which is convenient for you to prepare diversified samples

7. The furnace body is all stainless steel with water cooling to ensure that the temperature of the shell is lower than 35 °C to protect your personal safety

-

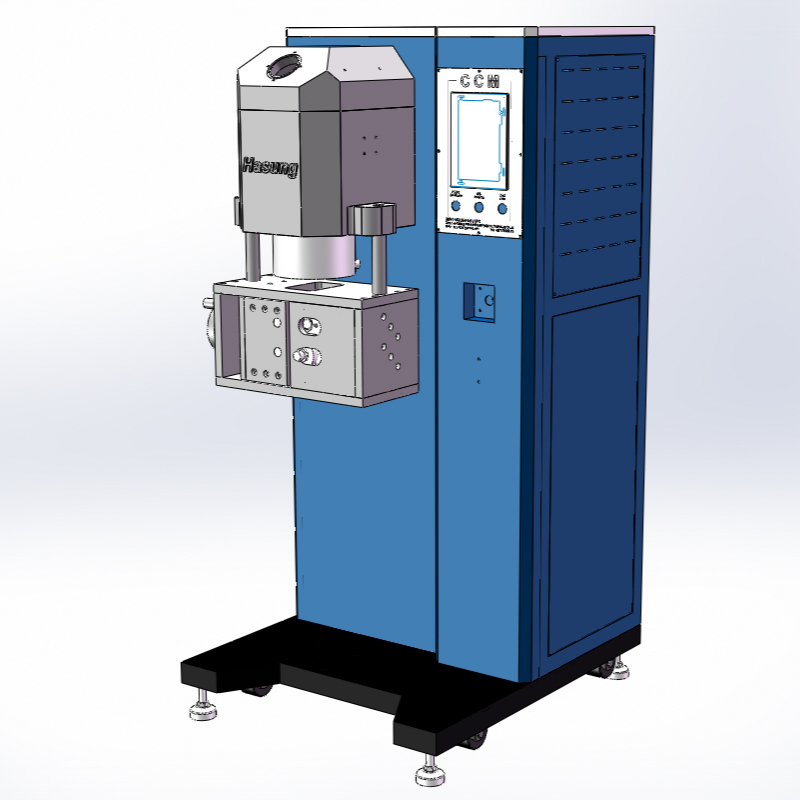

OEM Supply Manufacturing Gold Silver Continuous Copper Rod Casting Machine Equipment

The design of this equipment system is based on the actual needs of the project and process, using modern high-tech technology.

1. Using German high-frequency heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving and environmental protection, and high work efficiency.

2. The closed type + inert gas protection melting chamber can prevent the oxidation of molten raw materials and prevent the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or easily oxidized elemental metals.

3. Using a closed + inert gas protection melting chamber, melting and vacuuming are performed at the same time, the time is halved, and the production efficiency is greatly improved.

4. Melting in an inert gas environment, the oxidation loss of the carbon crucible is almost negligible.

5. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color.

6. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

7. Using PID temperature control system, the temperature is more accurate (±1°C). The HS-CC series continuous casting equipment is independently developed and manufactured with advanced technology and is dedicated to the melting and casting of gold, silver, copper and other alloys strips, rods, sheets, pipes, etc.

8. This equipment uses Mitsubishi PLC program control system, SMC pneumatic and Panasonic servo motor drive and other well-known brand components at home and abroad.

9. Melting, electromagnetic stirring, and refrigeration in a closed + inert gas protection melting room, so that the product has the characteristics of no oxidation, low loss, no pores, no segregation in color, and beautiful appearance.

-

Competitive Price for Industrial Double-Chamber Casting Sliver Copper Gold Ingots Melting Furnace

Why do You Choose Hasung vacuum Gold Bar Casting Machine ?

Hasung Vacuum Ingot Casting machines (HS-GV2) is designed for casting 2kg quality silver and gold bullions. This casting machine comes with the flexibility on moulds to customize your silver and gold bars, ingots and bullions with any of your designs and sizes.

The inert gas chamber of this gold silver bar casting machine ensures that you have a final casting with premium quality and mirror appearance by completely eliminating all forms of porosity, water waves or shrinkage in your final pieces.

Comparing with the traditional method. Your whole casting process will be done under vacuum and inert gas. Thereby giving your casting products a brilliant quality. With the above features your operators is fully guaranteed to operate our equipment easily.

Hasung’s original components are from well-known domestic and world famous brands like Japan AirTec, Taiwan Weinview, and German Siemens, Schneider, Omron, etc.

-

Wholesale Hasung Precious Metal Induction Smelting Furnace for Sale (HS-TF)

Tilting Melting Furnaces for melting large quantities of metal into ingots or bullions.

These machines are designed for melting large quantities, for example in the gold recycling factory for large capacity melting of 50kg or 100kg per batch.

Hasung TF series – tried and tested in foundries and precious metal refining groups.Our tilting smelting furnaces are mainly used in two areas:

1. for melting down large quantities of metal such as gold, silver or manufacturing metals industry like casting scraps, 15KW, 30KW, and maximum 60KW output and low-frequency tuning means fast melting which enjoys the best results from China – even for large volumes – and excellent through-mixing.

2. for casting large, heavy components after casting in other industries.

The compact and highly cost-effective tilting furnaces from TF1 to TF12 are used in the jewellery industry and in precious metal foundries, are completely new developments. They are equipped with new high performance induction generators that reach the melting point significantly faster and ensure thorough mixing and homogenisation of the molten metals. The TF20 to TF100 models, Depending on the model, the capacity ranges from a crucible volume of 20kg to 100kg for gold, mostly for precious metals manufacturing companies.

The TFQ series tilting furnaces are designed for both platinum and gold, all of metals such as platinum, palladium, stainless steel, gold, silver, copper, alloys etc, could be melted in one machine by changing crucibles only.

This type furnaces are great for platinum melting, thus when pouring, machine keeps heating until you almost finish pouring, then pour shuts down automatically when almost finished.

-

Factory best selling Customize Isostatic Graphite Mould for Silver Gold Ingot Bar Casting

Why do You Choose Hasung vacuum Gold Bar Casting Machine ?

Hasung Vacuum Ingot Casting machines (HS-GV2) is designed for casting 2kg quality silver and gold bullions. This casting machine comes with the flexibility on moulds to customize your silver and gold bars, ingots and bullions with any of your designs and sizes.

The inert gas chamber of this gold silver bar casting machine ensures that you have a final casting with premium quality and mirror appearance by completely eliminating all forms of porosity, water waves or shrinkage in your final pieces.

Comparing with the traditional method. Your whole casting process will be done under vacuum and inert gas. Thereby giving your casting products a brilliant quality. With the above features your operators is fully guaranteed to operate our equipment easily.

Hasung’s original components are from well-known domestic and world famous brands like Japan AirTec, Taiwan Weinview, and German Siemens, Schneider, Omron, etc.