Factory made hot-sale Vacuum Continuous Casting Machine For Alloys - Tunnel Type Gold Ingot Vacuum Casting System – Hasung

Factory made hot-sale Vacuum Continuous Casting Machine For Alloys - Tunnel Type Gold Ingot Vacuum Casting System – Hasung Detail:

A Logical Solution

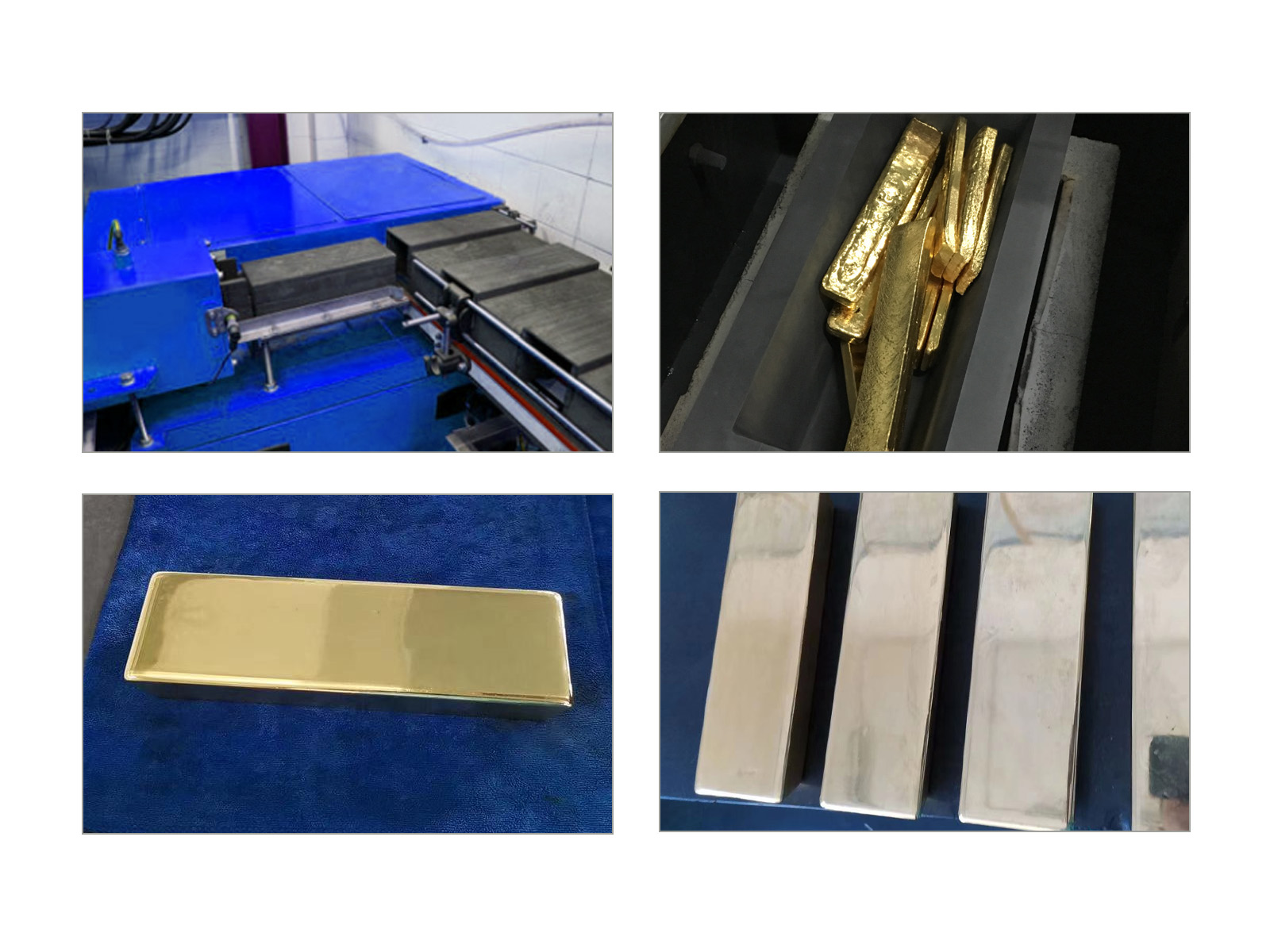

In the past years, the market of investment precious metals has become more and more demanding: nowadays an ingot must have the same aesthetic properties of a jewel.

Using the machines available on the market prior to the launch of HS-VF260, one could manufacture products of reasonable quality, but it was difficult for operators to manage them. As a matter of fact, calibration of work parameters and ordinary maintenance were almost exclusively limited to highly-specialized staff.

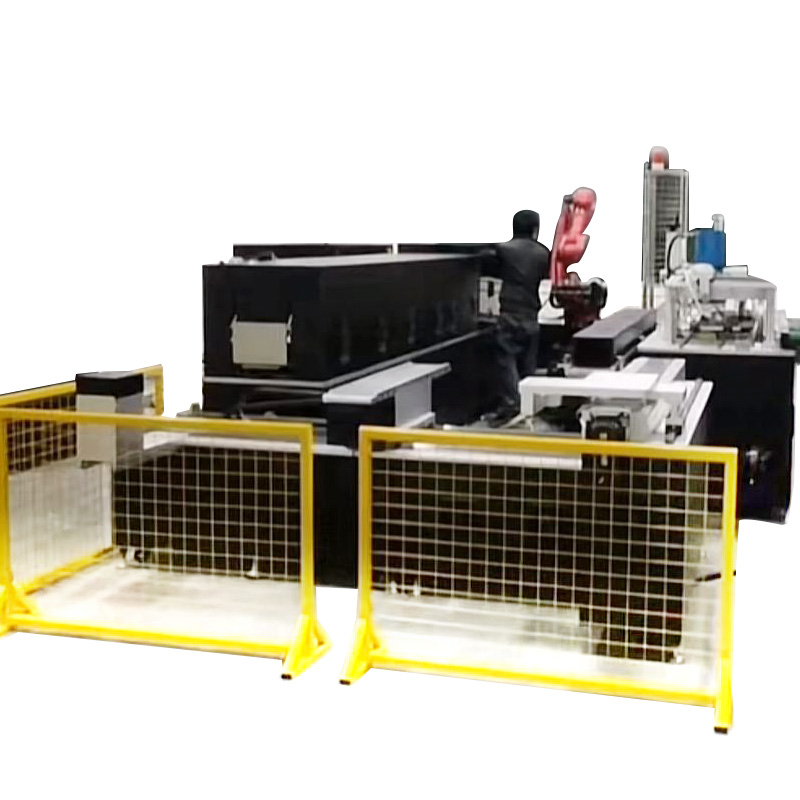

The launch of HS-VF260 revolutionized the field: companies all over the world were supplied with tailored tunnel furnaces, scalable according to production types (ingot from 1 ounce, up to 400 ounces or 1000 ounces), whose maintenance was accessible.

The only solution was designing an induction tunnel furnace with an easy and user-friendly interface (HMI touch screen), that could be even completely disassembled with just one wrench.

Critical Issues And Disadvantages Of The Traditional System

The furnace is in the open air and the flame is always burning, hence risks of accidents at work are very high.

Higher risks of metal loss.

Significant emission of fumes, whose recovery is very expensive for the company, and development of a strong electromagnetic field.

A lot of consumables, such as crucibles, are used and worn out quickly, implying high operating costs.

The quality of the finished ingot (shininess, purity, flatness) is medium-high.

The furnace requires the constant presence of operators.

Tunnel Furnace Gold Vacuum Casting System

Processing materials: 999.9 gold coins; Furnace control module: Triode ingot collection Gold weighs 15kg;

productivity: 4 blocks/hour, each block weighs 15kg;

Maximum working temperature: 1350-1400 degrees Celsius;

Type of protective gas: nitrogen; Air consumption: 5/H;

Furnace inlet water temperature and generator: up to 21 degrees Celsius;

Total water consumption: 12-13/H;

Required cooling water pressure: 3 to 3,5 bar;

Air flow required for ventilation: 0.1 m/s;

Required air pressure from the furnace: 6 bar;

Report Type and Separator: Graphite 400 oz;

The total area of the furnace installation is 18.2M2, the length is 26500mm, and the width is 2800mm.

The melting tunnel node is controlled by the following areas/worksites:

Unloading zone

Designed in stainless steel. Application: To pack gold particles into graphite sheets. Main

components: Electric push-step device displacement.

Input parameter area Use:

Restrict outdoor air from entering the tunnel Cooling system: water Main components: mobile partition with pneumatic control, nozzle Inject nitrogen.

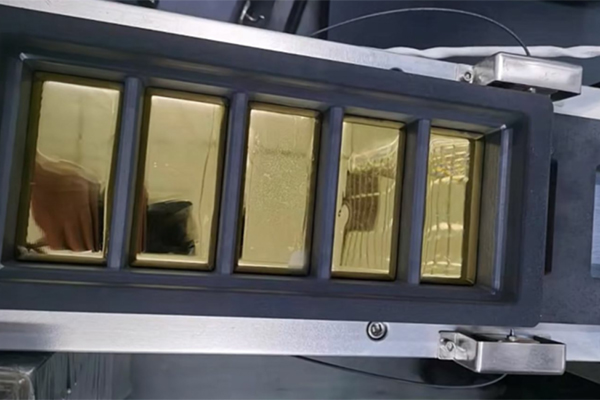

Melting zone Usage:

used for smelting gold particles Cooling system: water Main components: inductor lined with refractory cement, infrared

Temperature sensor, nitrogen delivery system

Cooling zone:

Purpose: to cool received ingots Cooling system: water Main components: mobile

partition with pneumatic control, nozzle Inject nitrogen. and vacuum.

Unloading zone:

Designed in stainless steel. Purpose:

Extract the finished product from the report.

Power Module, Overall Module: Power supply: 380v, 50Hz; 3 Phases Generator power:

60kW; others are 20KW. Total power required: 80KW

Control Zone:

Workspace for all furnaces

Product Display

Product detail pictures:

Related Product Guide:

We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We intention to create extra worth for our buyers with our prosperous resources, superior machinery, experienced workers and superb services for Factory made hot-sale Vacuum Continuous Casting Machine For Alloys - Tunnel Type Gold Ingot Vacuum Casting System – Hasung , The product will supply to all over the world, such as: Russia, Guatemala, Rotterdam, So far our merchandise have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have now 13years experienced sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to provide our customers with high quality items and excellent service.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.