Discount Price Powder Metallurgy Equipment - 3D Printing 10-50um Gold Powder Gas Atomizing Machines – Hasung

Discount Price Powder Metallurgy Equipment - 3D Printing 10-50um Gold Powder Gas Atomizing Machines – Hasung Detail:

Atomization pulverizing method is a new process developed in the powder metallurgy industry in recent years. It has the advantages of simple process, easy technology to master, material not easy to be oxidized, and high degree of automation.

1. The specific process is that after the alloy (metal) is melted and refined in the induction furnace, the molten metal liquid is poured into the heat preservation crucible and enters the guide tube and nozzle. At this time, the melt flow is blocked by the high-pressure liquid flow (or gas flow) The atomized and atomized metal powder is solidified and settled in the atomization tower, and then falls into the powder collecting tank for collection and separation. It is widely used in the field of non-ferrous metal powder making such as atomized iron powder, copper powder, stainless steel powder and alloy powder. The manufacturing technology of complete sets of iron powder equipment, copper powder equipment, silver powder equipment and alloy powder equipment is becoming more and more mature.

2. Use and principle of water atomization pulverizing equipment, water atomization pulverizing equipment is a device designed to meet the production of water atomization pulverizing process under atmospheric conditions, and it is an industrialized mass production device. The working principle of water atomization pulverizing equipment refers to the smelting of metal or metal alloy under atmospheric conditions. Under the condition of gas protection, the metal liquid flows through the thermal insulation tundish and the diversion pipe, and the ultra-high pressure water flows through the nozzle. The metal liquid is atomized and broken into a large number of fine metal droplets, and the fine droplets form sub-spherical or irregular particles under the combined action of surface tension and rapid cooling of water during the flight to achieve the purpose of milling.

3. The water atomization pulverizing equipment has the following characteristics: 1. It can prepare most of the metal and its alloy powder, and the production cost is low. 2. Subspherical powder or irregular powder can be prepared. 3. Due to the rapid solidification and no segregation, many special alloy powders can be prepared. 4. By adjusting the appropriate process, the powder particle size can reach a required range.

4. The structure of water atomization pulverizing equipment The structure of water atomizing pulverizing equipment consists of the following parts: smelting, tundish system, atomization system, inert gas protection system, ultra-high pressure water system, powder collection, dehydration and drying system, screening system, cooling water system, PLC control system, platform system, etc. 1. Melting and tundish system: In fact, it is an intermediate frequency induction melting furnace, which consists of: shell, induction coil, temperature measuring device, tilting furnace device, tundish and other parts: the shell is a frame structure, which is carbon Made of steel and stainless steel, an induction coil is installed in the middle, and a crucible is placed in the induction coil, which can be smelted and poured. The tundish is installed on the nozzle system, used to store molten metal liquid, and has the function of heat preservation. It is smaller than the crucible of the smelting system. The tundish holding furnace has its own heating system and temperature measurement system. The heating system of the holding furnace has two methods: resistance heating and induction heating. The resistance heating temperature can generally reach 1000 ℃, and the induction heating temperature can reach 1200 ℃ or higher, but the crucible material should be selected reasonably. 2. Atomization system: The atomization system consists of nozzles, high-pressure water pipes, valves, etc. 3. Inert gas protection system: In the process of pulverizing, in order to reduce the oxidation of metals and alloys and reduce the oxygen content of the powder, a certain amount of inert gas is usually introduced into the atomization tower for atmosphere protection. 4. Ultra-high-pressure water system: This system is a device that provides high-pressure water for atomizing nozzles. It consists of high-pressure water pumps, water tanks, valves, high-pressure hoses and busbars. 5. Cooling system: The whole device is equipped with water cooling, and the cooling system is essential. The temperature of the cooling water will be reflected on the secondary instrument to ensure the safe operation of the device. 6. Control system: The control system is the operation control center of the device. All operations and related data are transmitted to the PLC of the system, and the results are processed, saved and displayed through operations.

R&D and production of professional equipment for the preparation of new powder materials, providing professional series solutions for the production of advanced new powder materials, spherical powder preparation technology with independent intellectual property rights / round and flat powder preparation technology / strip powder preparation technology / flake powder preparation technology, as well as ultrafine/nano powder preparation technology, high chemical purity powder preparation technology.

Process Of Making Metal Powder By Water Atomization Pulverizing Equipment

The process of making metal powder by water atomization pulverizing equipment has a long history. In ancient times, people poured molten iron into water to make it burst into fine metal particles, which were used as raw materials for making steel; until now, there are still people who pour molten lead directly into water to make lead pellets. . Using the water atomization method to make coarse alloy powder, the process principle is the same as the above-mentioned water bursting metal liquid, but the pulverization efficiency has been greatly improved.

The water atomization pulverizing equipment makes coarse alloy powder. First, the coarse gold is melted in the furnace. The melted gold liquid must be overheated by about 50 degrees, and then poured into the tundish. Start the high-pressure water pump before the gold liquid is injected, and let the high-pressure water atomization device start the workpiece. The gold liquid in the tundish passes through the beam and enters the atomizer through the leaking nozzle at the bottom of the tundish. Atomizer is the key equipment for making coarse gold alloy powder by high-pressure water mist. The quality of the atomizer is related to the crushing efficiency of metal powder. Under the action of high-pressure water from the atomizer, the gold liquid is continuously broken into fine droplets, which fall into the cooling liquid in the device, and the liquid quickly solidifies into alloy powder. In the traditional process of making metal powder by high-pressure water atomization, the metal powder can be collected continuously, but there is a situation that a small amount of metal powder is lost with the atomizing water. In the process of making alloy powder by high-pressure water atomization, the atomized product is concentrated in the atomization device, after precipitation, filtration, (if necessary, it can be dried, usually directly sent to the next process.), to obtain fine Alloy powder, there is no loss of alloy powder in the whole process.

A complete set of water atomization pulverizing equipment The equipment for making alloy powder consists of the following parts:

Smelting part: an intermediate frequency metal smelting furnace or a high-frequency metal smelting furnace can be selected. The capacity of the furnace is determined according to the processing volume of metal powder, and a 50 kg furnace or a 20 kg furnace can be selected.

Atomization part: The equipment in this part is non-standard equipment, which should be designed and arranged according to the site conditions of the manufacturer. There are mainly tundishes: when the tundish is produced in winter, it needs to be preheated; Atomizer: The atomizer will come from high pressure The high-pressure water of the pump impacts the gold liquid from the tundish at a predetermined speed and angle, breaking it into metal droplets. Under the same water pump pressure, the amount of fine metal powder after atomization is related to the atomization efficiency of the atomizer; the atomization cylinder: it is the place where the alloy powder is atomized, crushed, cooled and collected. In order to prevent the ultra-fine alloy powder in the obtained alloy powder from being lost with water, it should be left for a period of time after atomization, and then placed in the powder collecting box.

Post-processing part: powder collecting box: used to collect the atomized alloy powder and separate and remove excess water; drying furnace: dry the wet alloy powder with water; screening machine: sieve the alloy powder, Out-of-specification coarser alloy powders can be re-melted and atomized as return material.

Vacuum Air Atomization Pulverizing Technology And Its Application

The powder prepared by vacuum air atomization has the advantages of high purity, low oxygen content and fine powder particle size. After years of continuous innovation and improvement, vacuum air atomization powder technology has developed into the main method of producing high-performance metal and alloy powders, and has become a leading factor supporting and promoting the research of new materials and the development of new technologies. The editor introduced the principle, process and powder milling equipment of vacuum air atomization, and analyzed the types and uses of powder prepared by vacuum air atomization.

The atomization method is a powder preparation method in which the fast-moving fluid (atomizing medium) impacts or otherwise breaks the metal or alloy liquid into fine droplets, which are then condensed into solid powder. The atomized powder particles not only have the exact same homogeneous chemical composition as the given molten alloy, but also due to the rapid solidification refines the crystalline structure and eliminates the macrosegregation of the second phase. The commonly used atomization medium is water or gas, which is called water atomization and gas atomization accordingly. The metal powders prepared by water atomization have high yield and economical yield, and the cooling rate is fast, but the powders have high oxygen content and irregular morphology, usually flakes. The powder prepared by gas atomization technology has small particle size, high sphericity and low oxygen content, and has become the main method for producing high-performance spherical metal and alloy powders.

Vacuum smelting high-pressure gas atomization pulverizing technology integrates high-vacuum technology, high-temperature smelting technology, high-pressure and high-speed gas technology, and is produced to meet the needs of powder metallurgy development, especially for the production of high-quality alloys containing active elements powder. Gas atomization pulverizing technology is a new rapid solidification technology. Due to the high cooling rate, the powder has the characteristics of grain refinement, uniform composition and high solid solubility.

In addition to the above advantages, the metal powder produced by vacuum smelting high-pressure gas atomization has the following three characteristics: pure powder, low oxygen content; high yield of fine powder; high appearance sphericity. Structural or functional materials made from this powder have many advantages over conventional materials in terms of physical and chemical properties. The developed powders include superalloy powder, thermal spray alloy powder, copper alloy powder and stainless steel powder.

1 Vacuum air atomization powder milling process and equipment

1.1 Vacuum air atomization powder milling process

The vacuum air atomization pulverizing method is a new type of process developed in the metal powder manufacturing industry in recent years. It has the advantages of not easy oxidation of materials, rapid quenching of metal powder, and high degree of automation. The specific process is that after the alloy (metal) is melted and refined in an induction furnace, the molten metal liquid is poured into the thermal insulation slump, and enters the guide tube and nozzle, and the melt flow is atomized by the high-pressure gas flow. The atomized metal powder solidifies and settles in the atomization tower, and falls into the powder collecting tank.

Atomizing equipment, atomizing gas and metal liquid flow are the three basic aspects of the gas atomization process. In the atomization equipment, the injected atomizing gas accelerates and interacts with the injected metal liquid flow to form a flow field. In this flow field, the molten metal flow is broken, cooled and solidified, thereby obtaining powder with certain characteristics. The parameters of atomization equipment include nozzle structure, catheter structure, catheter position, etc., atomization gas and its process parameters include gas properties, air inlet pressure, air velocity, etc., and metal liquid flow and its process parameters include metal liquid flow properties, superheat, liquid flow diameter, etc. Gas atomization achieves the purpose of adjusting powder particle size, particle size distribution and microstructure by adjusting various parameters and their coordination.

1.2 Vacuum air atomization pulverizing equipment

The current vacuum atomization pulverizing equipment mainly includes foreign equipment and domestic equipment. The equipment produced abroad has high stability and high control precision, but the equipment cost is high, and the maintenance and repair cost is high. The domestic equipment cost is low, the maintenance cost is low, and the maintenance is convenient. However, domestic equipment manufacturers generally do not master the core technologies of equipment such as atomizing nozzles and atomization processes. At present, relevant foreign research institutes and production enterprises keep the technology strictly confidential, and specific and industrialized process parameters cannot be obtained from relevant literature and patents. This makes the yield of high-quality powder too low to be economical, which is also the main reason why my country has not been able to industrially produce high-quality powder even though there are many aerosol powder production and scientific research units.

The structure of the gas atomization pulverizing device consists of the following parts: intermediate frequency induction melting furnace, holding furnace, atomization system, atomization tank, dust collection system, gas supply system, water cooling system, control system, etc.

At present, various researches on aerosolization mainly focus on two aspects. On the one hand, the parameters of the nozzle structure and the characteristics of the jet flow are studied. The purpose is to obtain the relationship between the airflow field and the nozzle structure, so that the airflow reaches the speed at the nozzle outlet while the gas flow rate is small, and provides a theoretical basis for the design and processing of the nozzle. On the other hand, the relationship between atomization process parameters and powder properties was studied. It aims to study the effect of atomization process parameters on powder properties and atomization efficiency on a nozzle-specific basis to optimize and guide powder production. In a word, improving the productivity of fine powder and reducing gas consumption leads the development direction of gas atomization technology.

1.2.1 Various types of nozzles for gas atomization

The atomizing gas increases the speed and energy through the nozzle, thereby effectively breaking the liquid metal and preparing the powder that meets the requirements. The nozzle controls the flow and flow pattern of the atomized medium, and plays a crucial role in the level of atomization efficiency and the stability of the atomization process, and is the key technology of gas atomization. In the early gas atomization process, the free-fall nozzle structure was generally used. This nozzle is simple in design, not easy to be blocked, and the control process is relatively simple, but its atomization efficiency is not high, and it is only suitable for the production of powder with a particle size of 50-300 μm. In order to improve the atomization efficiency, restrictive nozzles or tightly coupled atomizing nozzles were developed later. The tight or restrictive nozzle shortens the gas flight distance and reduces the kinetic energy loss in the gas flow process, thereby increasing the velocity and density of the gas flow interacting with the metal, and increasing the yield of fine powder.

1.2.1.1 Circumferential Slot Nozzle

High pressure gas enters the nozzle tangentially. Then it is ejected at high speed to form a vortex

To Develop 3D Printing, China Needs To Build Its Own Innovation Chain And Industrial Chain

In the past two years, the development of the additive manufacturing industry has risen to the national strategic level. Documents such as “Made in China 2025″ and “National Additive Manufacturing Industry Development Action Plan (2015-2016)” have been released. The additive manufacturing industry has developed rapidly. Vitality of technology-based enterprises is booming. Despite this, because the manufacturing industry is in the early stage of development, it still shows the characteristics of low scale. Experts admit that imported equipment is now aggressively “attacking” the Chinese market. Taking metal printing equipment as an example, foreign countries implement integrated bundled sales of materials, software, equipment and processes. my country must accelerate the research and development of core technologies and original technologies, and create its own innovation chain and industrial chain.

The market prospect is good

According to a McKinsey report, additive manufacturing ranks ninth among the 12 technologies that have a disruptive impact on human life, ahead of new materials and shale gas, and it is predicted that by 2030 additive manufacturing will reach A market size of around $1 trillion. In 2015, the report moved this process forward, arguing that by 2020, that is, three years later, the global additive manufacturing market size could reach a benefit of 550 billion US dollars. The McKinsey report is not sensational.

Lu Bingheng, academician of the Chinese Academy of Engineering and director of the National Additive Manufacturing Innovation Center, used “four and a half” to summarize the future market prospects of additive manufacturing.

More than half of the product value in the future is designed;

More than half of product production is customized;

More than half of the production models are crowdsourced;

More than half of innovations are made by makers.

Additive manufacturing is a disruptive technology that leads the development of the manufacturing industry. It is a suitable technology to support design innovation, customized production, maker innovation and crowdsourcing manufacturing. “More importantly, additive manufacturing is a rare technology that is synchronized with the world in my country. At present, China’s research on 3D printing is at the forefront of the world. “

Lu Bingheng said that at present, relying on the large-scale 3D printing metal atomization and milling equipment developed by my country itself, China is in the international position in the application of large-scale load-bearing parts of aircraft, and acts as a first-aid team in the research and development of military aircraft and large aircraft. Moreover, titanium alloy large-scale structural parts have been used in the research and development of aircraft landing gear and C919.

In terms of application, my country’s installed capacity of industrial-grade equipment ranks fourth in the world, but the commercialized equipment for metal printing is still relatively weak, and mainly relies on imports. However, according to Academician Lu Bingheng, the overall goal of China’s additive manufacturing is to achieve the world’s second largest installed capacity and the third largest equipment production and sales in the world within 5 years; and the world’s second largest installed capacity, core devices and original technologies, and equipment sales within 10 years. Achieve “Made in China 2025″ in 2035.

Industrial development accelerates

Data shows that the average growth rate of the market size of additive manufacturing in the past three years. The development rate of this industry in China is higher than the world average.

Signage: usually refers to what is done to regulate certain normative systems within the campus

Signs, such as: flower and grass signs, no climbing signs, etc. Declining, but in the service field, the growth rate is very fast due to the improvement of customer recognition. “Especially in product processing and manufacturing, our order volume has doubled.” The Weinan 3D Printing Industry Cultivation Base in Shaanxi Province, with the support of the local government, has transformed the advantages of 3D printing technology into industrial advantages and promoted the upgrading and transformation of traditional industries. A typical case of realizing cluster development.

Focusing on the industrial incubation concept of “3D printing +”, it is not simply to develop the 3D printing industry, but to focus on the production of 3D printing equipment, the research and development and production of 3D printing metal materials, and the training of 3D printing application-oriented talents. Rooted in local leading industries, focusing on the implementation of 3D printing industrialization demonstration applications, accelerating the integration of 3D printing with traditional industries, and implementing a series of 3D printing + industrial models such as 3D printing + aviation, automobile, cultural and creative, casting, education, etc., with the help of 3D printing The advantages of printing technology, solve the technical difficulties and pain points of traditional industries, transform and upgrade traditional industries, and introduce and incubate various types of small and medium-sized technology enterprises.

According to statistics, as of May 2017, the number of enterprises has reached 61, and more than 50 projects such as 3D molds, 3D, 3D industrial machines, 3D materials, and 3D cultural and creative projects have been reserved, which are expected to be implemented. It is expected that by the end of the year, the number of enterprises will exceed 100.

Activating the innovation chain and industrial chain

Despite the accelerated development of my country’s additive manufacturing industry, the industry is still in the early stages of development and still has the characteristics of low scale. However, the lack of technological maturity, high application cost, and narrow application scope have caused the industry as a whole to be in a state of “small, scattered and weak”. Although many companies have begun to set foot in the field of additive manufacturing, there is a lack of leading companies Driven, the scale of the industry is small. Academician Lu Bingheng said frankly that as one of the key technologies of the future industrial revolution, the development of additive manufacturing needs to be accelerated, because 3D printing technology is in a period of technological blowout, the start-up period of the industry, and the “staking” period of enterprises. The huge market demand can drive the development of a technology and an equipment field, which must be protected and fully utilized to guide and support our equipment manufacturing.

Now imported equipment is aggressively “attacking” the Chinese market. For metal printing equipment, foreign countries implement bundled sales of materials, software, equipment, and processes. Chinese companies must develop core technologies and original technologies to create their own innovation and industrial chains.

Industry insiders said that for the current domestic 3D printing industry, the degree of technology research and development has been completely applied to the industry, and many technological achievements are only in the laboratory stage. The main reasons for this problem are: first, due to various standards, access The qualifications are not perfect, and there are invisible barriers to entry; secondly, scientific research institutions and enterprises do not have scale effects, they are in a state of fighting alone, they lack the right to speak in industrial negotiations, and they are at a disadvantage; The new industry is poorly understood, and there are puzzles or misunderstandings, resulting in a slow pace of technology application.

The Development Trend Of Atomization Pulverizing Equipment In The Future

There are still many deficiencies in the understanding of 3D printing technology in all aspects of China’s manufacturing industry. Judging from the actual development situation, so far 3D printing has not achieved mature industrialization, from equipment to products to services still in the “advanced toy” stage. However, from the government to enterprises in China, the development prospects of 3D printing technology are generally recognized, and the government and society generally pay attention to the impact of the future 3D printing metal atomization pulverizing equipment technology on my country’s existing production, economy, and manufacturing models.

According to the survey data, at present, my country’s demand for 3D printing technology is not concentrated on equipment, but is reflected in the variety of 3D printing consumables and the demand for agency processing services. Industrial customers are the main force in purchasing 3D printing equipment in my country. The equipment they purchase is mainly used in aviation, aerospace, electronic products, transportation, design, cultural creativity and other industries. At present, the installed capacity of 3D printers in Chinese enterprises is about 500, and the annual growth rate is about 60%. Even so, the current market size is only about 100 million yuan per year. The potential demand for R&D and production of 3D printing materials has reached nearly 1 billion yuan per year. With the popularization and progress of equipment technology, the scale will grow rapidly. At the same time, 3D printing-related entrusted processing services are very popular, and many agents 3D printing The equipment company is very mature in the laser sintering process and equipment application, and can provide external processing services. Since the price of a single equipment is generally more than 5 million yuan, the market acceptance is not high, but the agency processing service is very popular.

Most of the materials used in my country’s 3D printing metal atomization pulverizing equipment are directly provided by rapid prototyping manufacturers, and the third-party supply of general materials has not yet been implemented, resulting in very high material costs. At the same time, there is no research on powder preparation dedicated to 3D printing in China, and there are strict requirements on particle size distribution and oxygen content. Some units use conventional spray powder instead, which has many inapplicability.

The development and production of more versatile materials is the key to technological advancement. Solving the performance and cost problems of materials will better promote the development of rapid prototyping technology in China. At present, most of the materials used in my country’s 3D printing rapid prototyping technology need to be imported from abroad, or the equipment manufacturers have invested a lot of energy and funds to develop them, which are expensive, resulting in increased production costs, while the domestic materials used in this machine have low strength and precision. . The localization of 3D printing materials is imperative.

Titanium and titanium alloy powders or nickel-based and cobalt-based superalloy powders with low oxygen content, fine particle size and high sphericity are required. The powder particle size is mainly -500 mesh, the oxygen content should be lower than 0.1%, and the particle size is uniform At present, high-end alloy powder and manufacturing equipment still mainly rely on imports. In foreign countries, raw materials and equipment are often bundled and sold to earn a lot of profits. Taking nickel-based powder as an example, the cost of raw materials is about 200 yuan/kg, the price of domestic products is generally 300-400 yuan/kg, and the price of imported powder is often more than 800 yuan/kg.

For example, the influence and adaptability of powder composition, inclusions and physical properties on the related technologies of 3D printing metal atomization powder milling equipment. Therefore, in view of the use requirements of low oxygen content and fine particle size powder, it is still necessary to carry out research work such as composition design of titanium and titanium alloy powder, gas atomization powder milling technology of fine particle size powder, and the influence of powder characteristics on product performance. Due to the limitation of milling technology in China, it is difficult to prepare fine-grained powder at present, the powder yield is low, and the content of oxygen and other impurities is high. During the use process, the powder melting state is prone to unevenness, resulting in high content of oxide inclusions and denser products in the product. The main problems of domestic alloy powders are in product quality and batch stability, including: ① stability of powder components (number of inclusions, uniformity of components); ② powder physical Stability of performance (particle size distribution, powder morphology, fluidity, loose ratio, etc.); ③ problem of yield (low yield of powder in narrow particle size section), etc.

Technical Parameters

| Model No. | HS-MI10 | HS-MI30 |

| Voltage | 380V 3 Phases, 50/60Hz | |

| Power Supply | 15KW | 30KW |

| Max Temp | 2200°C | |

| Casting Time | 15 Min. | 30 Min. |

| Casting Grains | 80#-200# | |

| Temp Accuracy | ±1°C | |

| Capacity | 10kg (Gold) | 30kg (Gold) |

| Vacuum Pump | German vacuum pump, vacuum degree – 100Kpa (optional) | |

| Application | Platinum(Optional), Gold, silver, copper | |

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | |

| Control System | Mitsubishi PLC+Human-machine interface intelligent control system (optional) | |

| Shielding Gas | Nitrogen/Argon | |

| Cooling type | Water chiller (Sold separately) | |

| Dimensions | 1180x1070x1925mm | 3575*3500*4160mm |

| Weight | approx. 160kg | approx. 2150kg |

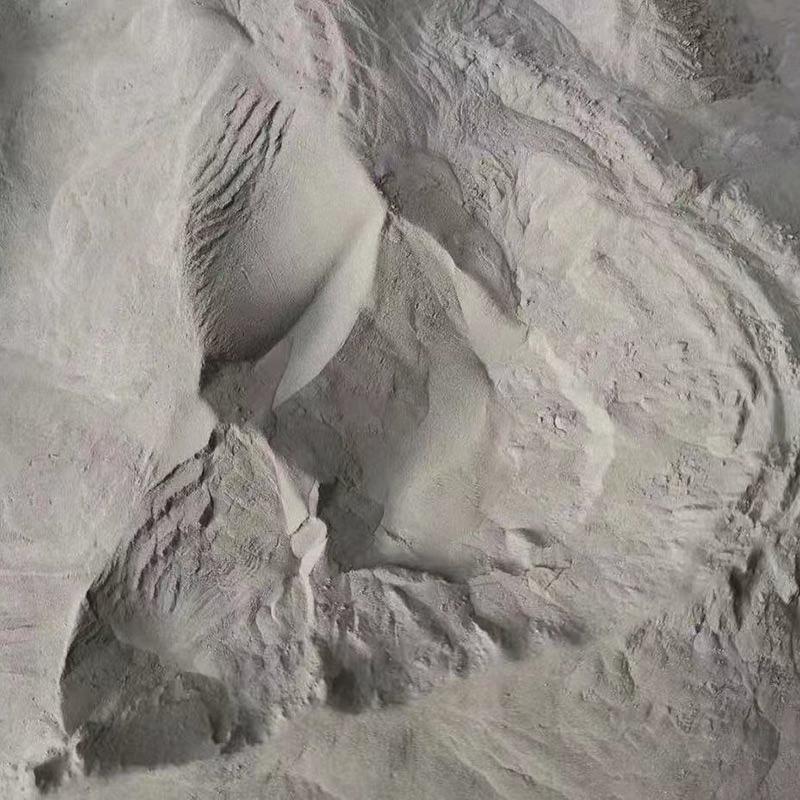

Product Display

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, believe in the 1st and management the advanced" for Discount Price Powder Metallurgy Equipment - 3D Printing 10-50um Gold Powder Gas Atomizing Machines – Hasung , The product will supply to all over the world, such as: kazakhstan, Nepal, Somalia, There are advanced producing & processing equipment and skilled workers to ensure the products with high quality. We have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our products are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.