Continuous Casting Machines

The function principle of ordinary type continuous casting machines is based on similar ideas as our vacuum pressure casting machines. Instead of filling the liquid material into a flask you can produce/draw sheet, wire, rod, or tube by using a graphite mold. All this happens without any air bubbles or shrinking porosity. The vacuum and high vacuum continuous casting machines are basically used for making high-end quality wires such as bonding wire, semiconductor, aerospace field.

-

Hasung-High Vacuum Continuous Casting Equipment For Precious Metals

Applicable metals: metal materials such as gold, K gold, silver, copper, and their alloys

Application industries: bonding wire materials, jewelry casting, precious metal processing, university laboratories and other related fields

Product advantages:

1. High vacuum (6.67×10-3pa), high vacuum melting, high product density, low oxygen content, no pores, suitable for producing high-quality bonding wire;

2. Anti oxidation, inert gas protection refining, to solve the problem of alloy oxidation;

3. Uniform color, electromagnetic and physical stirring methods make the alloy color more uniform;

4. The finished product has a smooth surface and adopts a downward pull design. The traction wheel has undergone special treatment, and the finished product has no damage to the surface and a smooth surface;

5. Precise temperature control ± 1 ℃, using imported temperature control meters and intelligent PID temperature control system, with a temperature difference of ± 1 ℃;

6. 7-inch full-color touch screen, more convenient to view/touch, new system, simple UI interface, easy to operate with just one touch;

7. Multiple protection, multiple security protection, worry free use

-

Precious Metals Horizontal Vacuum Continous Casting Machine

Horizontal vacuum continuous casting machine Advantages

1. Improve product quality

2. Enhanced process control

3. Increased Productivity

4. Energy efficiency

Characteristics of horizontal vacuum continuous casting machine

1. Horizontal Casting Design

2. Vacuum Chamber

3. Cooling system

4. Automation and control system

5. Large melting capacity

6. Good quality casting product

-

Continuous Casting Machine for Gold Silver Copper Alloy 20kg 30kg 50kg 100kg

1.As soon as silver gold strip wire tube rod continuous casting machine for jewelry was launched on the market, it received positive feedback from many customers, who said that this type of product can effectively solve their needs.Moreover,the product is widely used in Metal Casting.

2.Continuous Casting Machine for Making Rod Strip Pipe with 20kg 30kg 50kg 100kg compared with similar products on the market, it has incomparable outstanding advantages in terms of performance, quality, appearance, etc., and enjoys a good reputation in the market.Hasung summarizes the defects of past products, and continuously improves them. The specifications of Continuous Casting Machine for Making Rod Strip Pipe with 20kg 30kg 50kg 100kg can be customized according to your needs.

-

High Vacuum Continuous Casting Machine For New Materials Casting Bonding Gold Silver Copper Wire

Casting of electronic materials such as bond alloy silver copper wire and high-purity special wire The design of this equipment system is based on the actual needs of the project and process, and makes full use of modern high-tech technology.

1. Adopt German high-frequency heating technology, automatic frequency tracking and multiple protection technology, which can melt in a short time, save energy and work efficiently.

2. The closed type + inert gas protection melting chamber can prevent the oxidation of molten raw materials and the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or easily oxidized elemental metals.

3. Use closed + inert gas to protect the melting chamber. When melting in an inert gas environment, the oxidation loss of the carbon mold is almost negligible.

4. With the function of electromagnetic stirring + mechanical stirring under the protection of inert gas, there is no segregation in color.

5. Using Mistake Proofing (anti-fool) automatic control system, the operation is more convenient.

6. Using PID temperature control system, the temperature is more accurate (±1°C).

7. HVCC series high vacuum continuous casting equipment is independently developed and manufactured, with advanced technology, used for continuous casting of high purity gold, silver, copper and other alloys.

8. This equipment uses Mitsubishi PLC program control system, SMC pneumatic and Panasonic servo motor drive and other domestic and foreign brand components.

9. Melting in a closed + inert gas protection melting room, double feeding, electromagnetic stirring, mechanical stirring, refrigeration, so that the product has the characteristics of no oxidation, low loss, no porosity, no segregation in color, and beautiful appearance.

10. Vacuum Type: High vacuum.

-

Vacuum Continuous Casting Machine for Gold Silver Copper Alloy

Unique vacuum continuous casting system

For highest quality of semi-finished material:

To reduce the risk of oxidation during melting and during drawing, we focus on avoiding oxygen contact and on fast reduction of the temperature of the drawn metal material.

Features to avoid oxygen contact:

1. Inert gas system for the melting chamber

2. Vacuum system for the melting chamber – uniquely available for Hasung vacuum continuous casting machines (VCC series)

3. Inert gas flushing at the die

4. Optical die temperature measurement

5. Additional secondary cooling system

6. All these measures are ideal especially for alloys containing copper such as red gold or for silver as these materials tend to oxidise easily.Drawing process and situation could be easily oberseved by observing windows.

Vacuum degrees could be according to customers’ request.

-

Continuous Casting Machine for Gold Silver Copper Alloy

The design of this equipment system is based on the actual needs of the project and process, using modern high-tech technology.

1. Using German high-frequency heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving and environmental protection, and high work efficiency.

2. The closed type + inert gas protection melting chamber can prevent the oxidation of molten raw materials and prevent the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or easily oxidized elemental metals.

3. Using a closed + inert gas protection melting chamber, melting and vacuuming are performed at the same time, the time is halved, and the production efficiency is greatly improved.

4. Melting in an inert gas environment, the oxidation loss of the carbon crucible is almost negligible.

5. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color.

6. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

7. Using PID temperature control system, the temperature is more accurate (±1°C). The HS-CC series continuous casting equipment is independently developed and manufactured with advanced technology and is dedicated to the melting and casting of gold, silver, copper and other alloys strips, rods, sheets, pipes, etc.

8. This equipment uses Mitsubishi PLC program control system, SMC pneumatic and Panasonic servo motor drive and other well-known brand components at home and abroad.

9. Melting, electromagnetic stirring, and refrigeration in a closed + inert gas protection melting room, so that the product has the characteristics of no oxidation, low loss, no pores, no segregation in color, and beautiful appearance.

What is continuous casting, what is it for, what are the advantages?

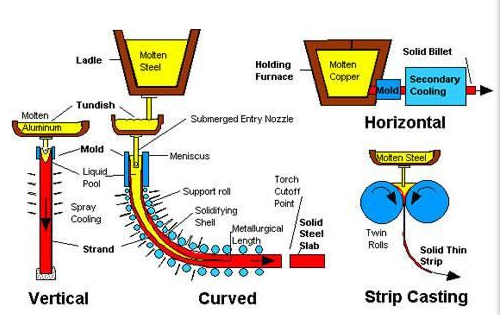

The continuous casting process is a very effective method to manufacture semi-finished products such as bars, profiles, slabs, strips and tubes made from gold, silver and non-ferrous metals such as copper, aluminium and alloys.

Even if there are different continuous casting techniques, there is no significant difference in casting gold, silver, copper or alloys. The essential difference are the casting temperatures which range from approximately 1000 °C in the case of silver or copper to 1100 °C in the case of gold or other alloys. The molten metal is continuously cast into a storage vessel called ladle and flows from there into a vertical or horizontal casting mould with open end. While flowing through the mould, which is cooled with crystallizer, the liquid mass takes the profile of the mould, starts to solidify at its surface and leaves the mould in a semi-solid strand. Simultaneously, new melt is constantly supplied to the mould at the same rate to keep up with the solidifying strand leaving the mould. The strand is further cooled by means of a water spraying system. Through the use of intensified cooling it is possible to increase the speed of crystallization and to generate in the strand a homogeneous, fine-grained structure giving the semi-finished product good technological properties. The solidified strand is then straightened and cut to desired length by shears or a cutting-torch.

The sections can be further worked upon in subsequent in-line rolling operations to obtain bars, rods, extrusion billets (blanks), slabs or other semi-finished products in various dimensions.

History of continuous casting

The first attempts to cast metals in a continuous process were made in the middle of the 19th century. In the year 1857, Sir Henry Bessemer (1813–1898) received a patent for casting metal between two contra-rotating rollers for manufacturing metal slabs. But that time this method remained without attention. Decisive progress was made from 1930 onwards with the Junghans-Rossi technique for continuous casting of light and heavy metals. Concerning steel, the continuous casting process was developed in 1950, before (and also after) that steel was poured into a stationary mould to form 'ingots'.

The continuous casting of non-ferrous rod was created by the Properzi process, developed by Ilario Properzi (1897-1976), the founder of the Continuus-Properzi company.

The advantages of continuous casting

Continuous casting is the perfect method for manufacturing semi-finished products of long sizes and enables the production of large quantities within short time. The microstructure of the products is even. Compared to casting in moulds, continuous casting is more economic regarding the consumption of energy and reduces less scrap. Furthermore, the properties of the products can be easily modified by changing the casting parameters. As all operations can be automatized and controlled, continuous casting offers numerous possibilities to adapt the production flexibly and rapidly to changing market requirements and to combine it with digitization (Industrie 4.0) technologies.