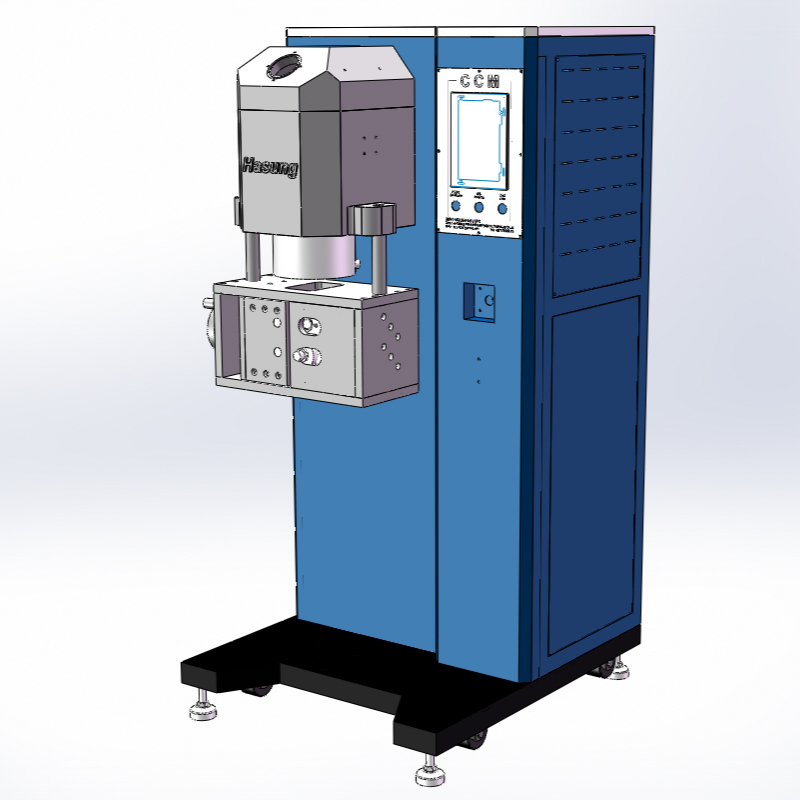

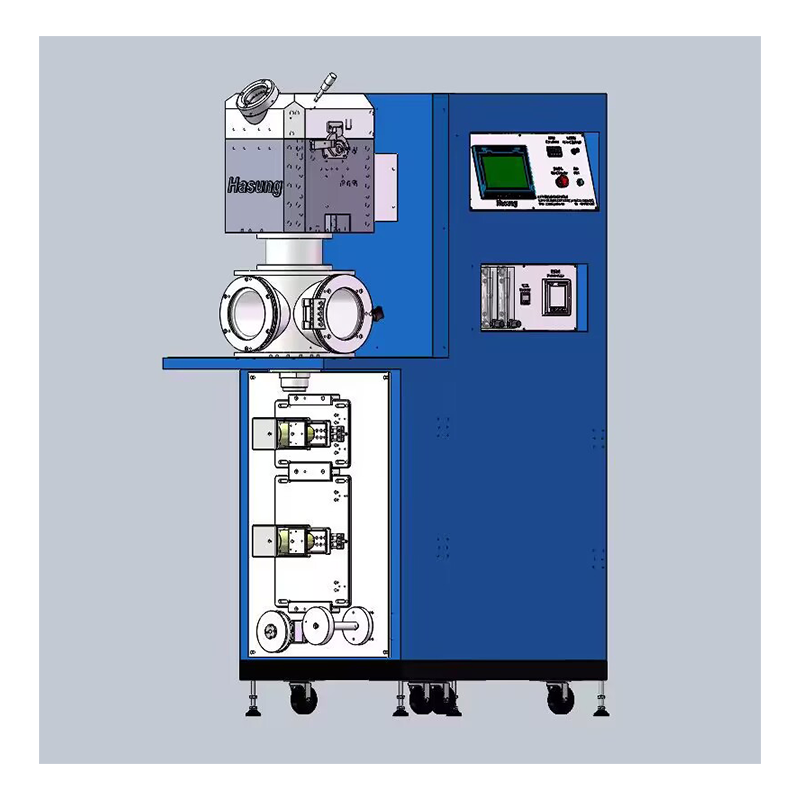

Continuous Casting Machine for Gold Silver Copper Alloy

Technical Parameters

| Model No. | HS-CC3 | HS-CC4 | HS-CC5 | HS-CC6 | HS-CC8 |

| Voltage | 380V 50/60Hz,3 phase | ||||

| Power | 15KW | 20KW | |||

| Max. Temp. | 1500C | ||||

| Melting speed | 2-4mins. | 3-5mins. | 4-6mins. | ||

| Capacity (Gold) | 3kg | 4kg | 5kg | 6kg | 8kg |

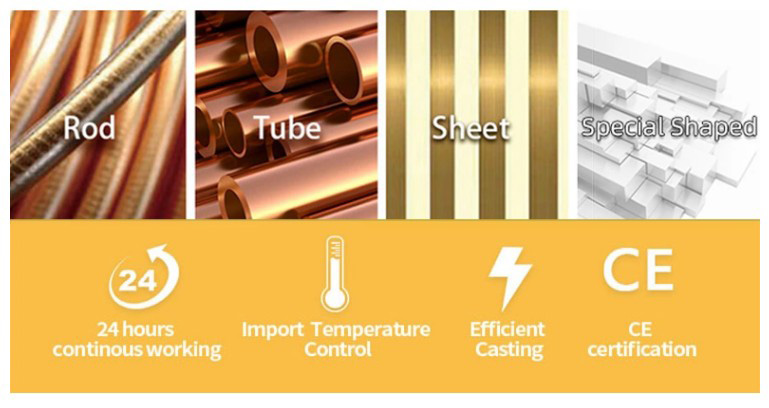

| Suitable for | Gold, karat gold, silver, copper | ||||

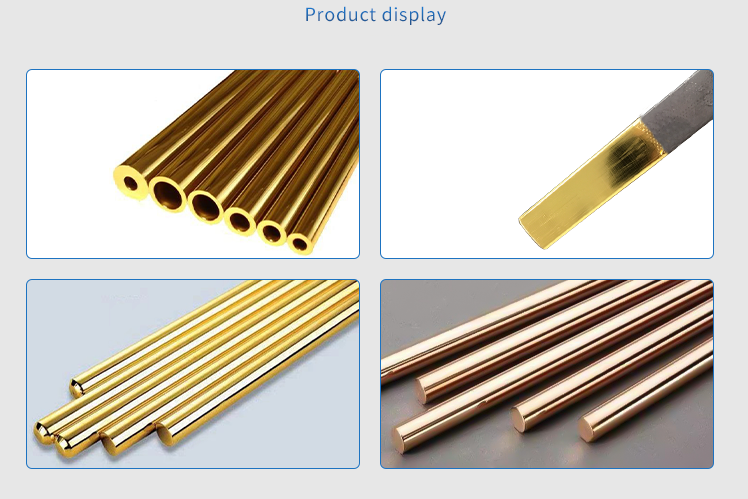

| Casting product | Rods, strips, plates, hexagon, square, etc. | ||||

| Operation method | Manual control | ||||

| Temp Control System | PID | ||||

| Heating method | Germany IGBT Induction heating technology | ||||

| Cooling method | Water cooling (water chiller) | ||||

| Dimensions | 800*860*1560 | ||||

| Weight (approx.) | approx. 200KG | ||||

Product Display

Wire Processing Equipment

Wire Continuous Rolling Mill for Gold Silver Copper

Model No.: HS-3000

Rolling mill Machine Wire Drawing Machine for Gold Silver Chain Wire

|

Voltage

|

380V, 50Hz, 3 Phases

|

|

Power

|

8KW

|

|

Roller diameter

|

96mm(Roller material: SKD11)

|

|

Roller quantity

|

12 pairs

|

|

Processing material range

|

input 8.2x8.2mm; output 3.5x3.5mm or input 3.5x3.5mm; output 1.0x1.0mm

|

|

Max rolling speed

|

45 m/min. (925 silver: approx. 4.9kg)

|

|

Dimensions

|

2800x900x1300mm

|

|

Weight: approx

|

2500kg

|

|

Control system

|

frequency speed control, motor drive rolling

|

|

Wire collection way

|

Sagging Gravity take-up

|

|

Material cooling

|

Spray lubricating fluid cooling

|

|

Application

|

Gold, K-gold, Silver, Copper, alloy.

|

Heavy Duty Wire Drawing Machine for Gold Silver Copper

Model No.: HS-1126

It is a heavy duty type wire drawing system, application for gold, silver, copper, etc. Drawing ability up to 8mm, minimum size could be 0.2mm. It is used for precious metals wire processing, widely used for metal wires manufacturing industry.|

Voltage

|

380V, 50Hz, 3 Phases |

| Power | 5.5KW*2 |

| Drawing wire diameter | 0.2-8mm |

| Roller hardness | 60-62 HRC |

| Processing material range | gold, K-gold, Silver, Copper, alloy, etc |

| Max rolling speed | 32m/min. |

| Motor speed | 36rpm/min. (speed control) |

| Dimensions | 1900x800x1400mm |

| Weight: approx | approx. 900kg |

| Wire collection device | Included |

| Material cooling | Spray water cooling |

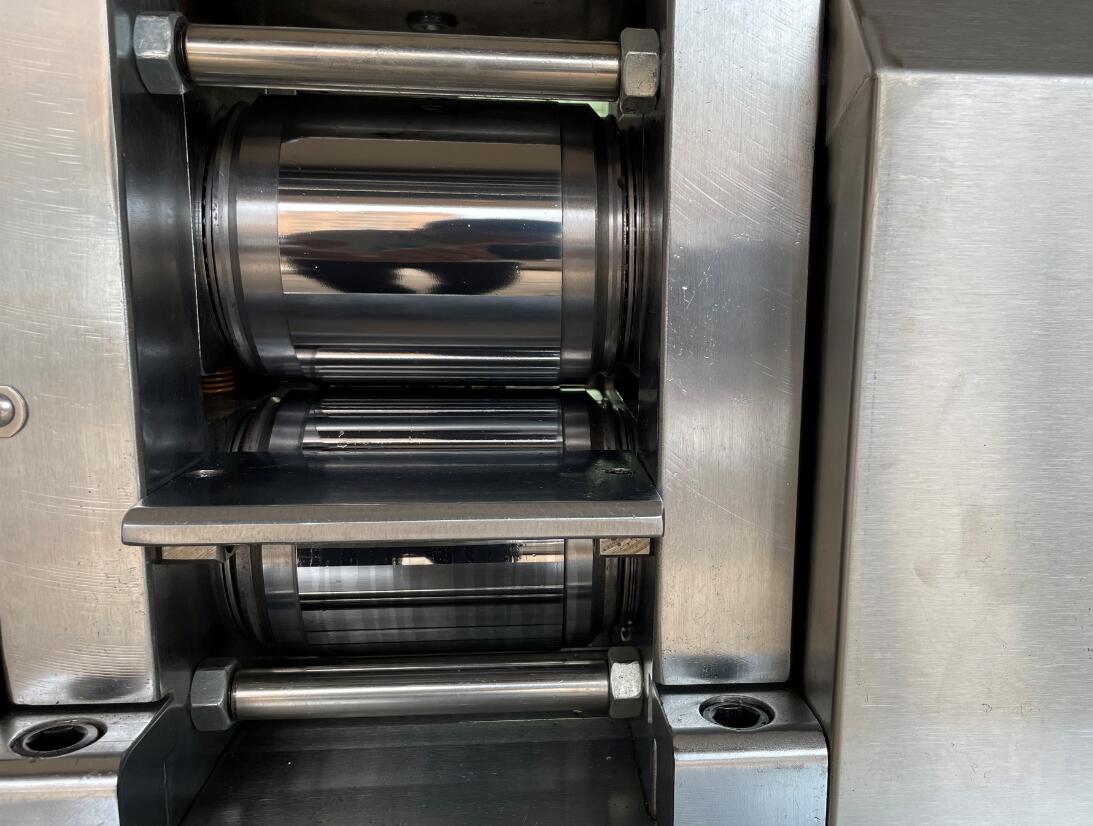

8HP Double Head Electric Wire Rolling Mill (double speed)

Heavy duty type double head wire rolling mill machine is applied for jewellery factories and precious metals industry. It is equipped with wire winding device. Easily for wire manufacturers.

For jewellery factories, mostly they use it making wires, then making many types of link chains for gold and silver, copper materials. Wire and sheet sizes could be customized by this machine according to requests.

|

Model No.

|

HS-D8HP

|

|

Voltage

|

380V, 50/60Hz

|

|

Power

|

5.5KW

|

|

Roller

|

diameter 130/120 × width 188mm

|

|

Roller hardness

|

60-61 °

|

|

Dimensions

|

1080 × 1180 × 1480mm

|

|

Weight

|

Approx. 850kg

|

|

Additional function

|

automatic lubrication; gear transmission

|

|

Features

|

Rolling 0.9-10.5mm square wire; double speed; smooth surface of the wire, accurate size, no low front loss; automatic take-up;

electrostatic dusting of the frame, decorative hard chromium |

12 Pass Wire Drawing Machine

The wire drawing machine, also called wire passing machine, it is used for reducing wire sizes. This machine equipped with 12 pass which allows you to put 12 wire dies at a time. The capability for this machine is from maximum 1.2mm to minimum 0.1mm. It is a necessary machine for ewelry chain manufacturing plant. It is also used for other precious metal wires manufacturing purposes.

|

Model No.

|

HS-1124

|

|

Voltage

|

380V 3 phase , 50/60Hz

|

|

Power

|

3.5KW

|

|

Fastest Speed

|

55 meters / minute

|

|

Capability

|

1.2mm - 0.1mm

|

|

Cooling way

|

Automatic liquid cooling

|

|

Wire moulds

|

customized (sold separately)

|

|

Machine size

|

1680*680*1280mm

|

|

Weight

|

Approx. 350kg

|

Sheet Processing Equipment

10HP Sheet Rolling Mill

| MODEL NO. | HS-8HP | HS-10HP |

| Brand Name | HASUNG | |

| Voltage | 380V 50/60Hz, 3 phases | |

| Power | 5.5KW | 7.5KW |

| Roller | diameter 130/120 × width 248mm | diameter 150 × width 220mm |

| hardness | 60-61 ° | |

| Dimensions | 980×1180×1480mm | 1080x 580x1480mm |

| Weight | approx. 600kg | approx. 800kg |

| Capability | Maximum Rolling thickness is up 25mm | Maximum Rolling thickness is up to 35mm |

| Advantage | The frame is electrostatically dusted, the body is plated with decorative hard chrome, and the stainless steel cover is beautiful and practical without rust. single-speed / double speed | |

| After Warranty Service | Video technical support, Online support, Spare parts, Field maintenance and repair service | |

Tungsten Carbide Mirror Surface Sheet Rolling Mill

|

Model No.

|

HS- M5HP

|

HS- M8HP

|

|||

|

Brand Name

|

Hasung

|

||||

|

Voltage

|

380V 3 phases; 50/60hz

|

||||

|

Power

|

3.7kw

|

3.7kw

|

5.5kw

|

||

|

Tungsten Roller size

|

diameter 90 × width 60mm

|

diameter 90 × width 90mm

|

diameter 100 × width 100mm

|

diameter 120 × width 100mm

|

|

|

hardness

|

92-95 °

|

||||

|

Material

|

imported tungsten steel billet

|

||||

|

Dimensions

|

880×580× 1400mm

|

880×580× 1400mm

|

880×580× 1400mm

|

||

|

Weight

|

approx. 450kg

|

approx. 450kg

|

approx. 480kg

|

||

|

Feature

|

With lubrication, gear drive; Rolling sheet thickness 10mm, thinnest 0.1mm; extruded sheet metal surface mirror effect; static powder spraying on the frame, decorative hard chrome plating, stainless steel

|

||||

Making strips, rods, sheets, pipes, etc.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur