Automatic Gold Bar Vacuum Casting Machine 60KG

Features

1. Intelligent Fully Automatic Vacuum Gold Bar Casting:

1).Simple operation for beginners: Presssing one key can complete the entire casting process -- Automatic close the cover--Automatic vacuum and inert gas -- Automatic casting and cooling--Automatic open the cover.

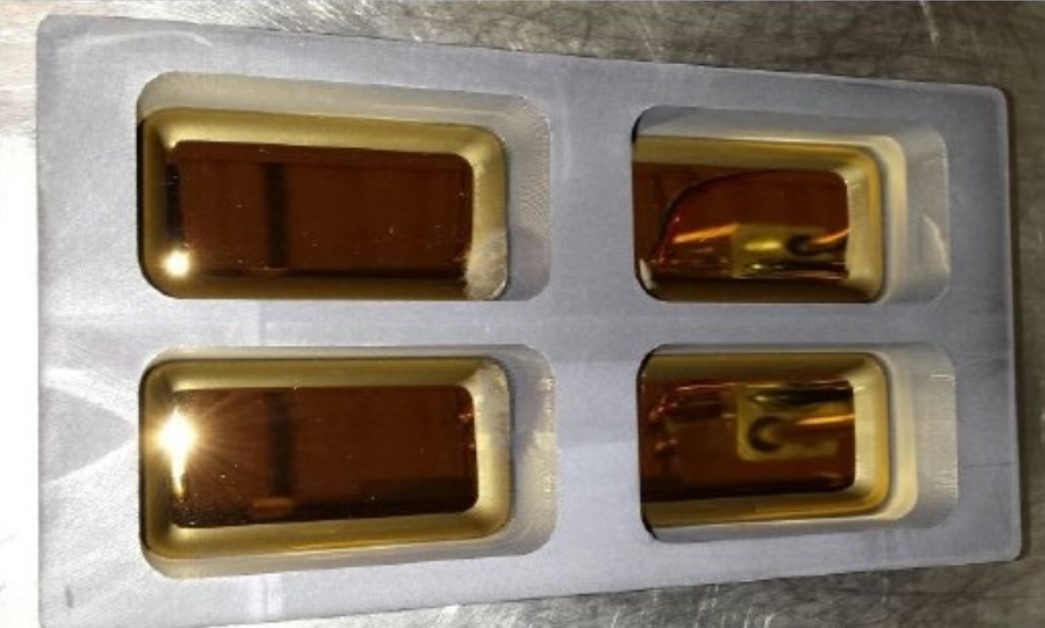

2).Take out the Shiny gold Bar

2. With Taiwan 10" PLC touch screen control system, Siemens touch screen is optional.

3. Can set 100 programs

4. Using German IGBT induction heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving, and high work efficiency.

4. Melting under vacuum and inert gas protection atomophere which can prevent the oxidation of molten raw materials and without shrinkage, bubbles, etc. This equipment is suitable for the casting of high-purity gold silver materials.

5. With servo motor drive for auto open and close device which makes steady and high quality moving.

6. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

7. This equipment uses Twaiwan PLC program control system or Siemens, Japan SMC/AirTec pneumatic components, Germany Omron, Schneider and Panasonic servo motor drive and other domestic and foreign brand components.

8. No oxidation, low loss, no porosity, no segregation in color, and beautiful appearance.

Technical Parameters

| Model No. | HS-GV12 | HS-GV30 | HS-GV60 | ||

| Automatic Opening Cover Gold Bar Vacuum Casting Machine | |||||

| Power Supply | 380V, 50/60Hz, 3 phase | ||||

| Power Input | 50KW | 60KW | 70KW | ||

| Max Temp | 1500°C | ||||

| Casting Cycle Time | 12-15mins. | 18-25mins. | 20-28mins. | ||

| Shielding Gas | Argon / Nitrogen | ||||

| Temperature Accuracy | ±1°C | ||||

| Capacity (Au) | 12kg: 1 pcs 12kg, or more. | 30kg: 1pcs 30kg, or more | 60kg (30kg silver): 1pcs 30kg silver, or 1pcs 30kg gold or more | ||

| Application | Gold,Silver,Platinum,Palladium (When by Pt, Pd, customized) | ||||

| Vacuum Pump | High quality vacuum pump/German Vacuum Pump, Vacuum degree-100KPA | ||||

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | ||||

| Control system | 10" Taiwan Weinview/Siemens PLC intelligent control system (optional) | ||||

| Cooling type | Water chiller(sold separately) or Running water | ||||

| Dimensions | 1460*720*1010mm | 1530x720x1060mm | 1530x720x1060mm | ||

| Weight | 350KG | 360KG | 400KG | ||

When it's 30 kilos single gold bar or silver bar, it's recommended to equip with mechanical arm.

Product Display

-1.png)

Dot Peen Marking Machine

Technical specifications:

| Voltage | 220V |

| Print range | 140*80mm |

| Power | 150W |

| Support system | WindowsXP or Win7 |

| System imprint depth | 0.01-1mm (material dependent) |

| Speed | about 1 second 1 number 5 |

| Using workpiece | all kinds of precious metals |

| Dimensions | 400*300*750mm |

| Net weight | approx. 43KG |

| Standard effective height | 330mm |

| Air source pressure | 0.2-0.6mpa |

Pneumatic serial number marking machine for gold silver bars: (computer and air source 8mm windpipe should be provided by buyer).

Revolutionizing 30KG gold sivler bar casting with Hasung’s cutting-edge casting machine

In the world of precious metals, the process of casting gold bars has always been a meticulous and time-consuming task. However, with the advent of the Hassan Gold Ingot Casting Machine, the rules of the game completely changed. This innovative technology enables the casting of single 30kg gold bars in an extremely short time while also delivering high-quality results when casting silver bars of the same weight. Let’s delve into the features and benefits of this groundbreaking machine and explore how it revolutionized the gold casting industry.

Hasung gold bar casting machines are industry game changers, delivering unparalleled efficiency and precision. The ability to cast a single 30kg gold bar significantly reduces the time and labor required for the process. This means gold foundries can now increase production capacity to meet growing demand for gold bars in a more timely manner. In addition, the machine is capable of casting 30kg silver bars at high quality, further extending its versatility and attracting a wider range of precious metals manufacturers.

One of the key features that sets Hasung gold bar casting machines apart is their advanced technology and precision engineering. The machine is equipped with a state-of-the-art casting mechanism that ensures accurate and consistent formation of gold and silver bars. This level of precision is critical to producing high-quality gold bars, as even the slightest imperfections can seriously affect the value and marketability of the final product. With Hasung's machines, manufacturers can be confident in the quality and integrity of the gold bars they produce.

In addition to its impressive casting capabilities, the Hasung gold bar casting machine features a user-friendly interface and intuitive controls. This makes it accessible to a variety of operators regardless of their experience level in gold casting. The machine’s user-friendly design simplifies the casting process, allowing operators to efficiently oversee the production of gold nuggets with minimal training or supervision. Not only does this increase productivity, it also reduces the chance of errors or inconsistencies in the casting process.

Additionally, Hasung gold bar casting machines are designed with durability and longevity in mind. Its sturdy construction and high-quality materials ensure it can withstand the rigors of continuous operation, making it a reliable long-term investment in gold casting equipment. This durability is critical in an industry where gold bullion demand is constant and any downtime or equipment failure can have a significant impact on production schedules and profitability.

Another significant advantage of the Hasung gold bar casting machine is its energy efficiency and environmental sustainability. By optimizing the casting process and minimizing waste, the machine helps reduce the overall environmental impact of gold bar production. This is in line with the precious metals industry’s growing focus on sustainable and responsible practices, allowing manufacturers to meet market demand while minimizing their ecological footprint.

The impact of the Hasung Gold Ingot Casting Machine goes beyond its direct function as it also contributes to the overall advancement of gold casting technology. Its innovative design and functionality set new standards for industry efficiency and quality, prompting other manufacturers to strive for similar advancements. This healthy competition and drive for innovation ultimately benefits the entire gold casting industry, leading to overall improvements in processes and products.

Additionally, the Hasung gold ingot casting machine has the potential to open up new opportunities for gold casting facilities, allowing them to take on larger-scale projects and meet the changing needs of the market. The machine is capable of casting 30kg single-piece gold bars, enabling the manufacturer to achieve ambitious production targets and meet the needs of a wider range of customers and industry. This expansion of capabilities can lead to increased revenue and growth for businesses adopting this cutting-edge technology.

In summary, the Hasung gold bar casting machine represents a major leap forward in gold casting, delivering unprecedented efficiency, precision and versatility. Its ability to cast 30kg single gold bars in a short time, as well as its high-quality results when casting silver bars, makes it a game-changer for the industry. As manufacturers continue to adopt this innovative technology, the landscape of gold bar production will transform, paving the way for increased productivity, sustainability and market competitiveness. With Hasung machines leading the way, the future of gold casting looks brighter than ever.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur