2022 High quality Gold Making - VC Series Jewelry Vacuum Pressure Casting Machine – Hasung

2022 High quality Gold Making - VC Series Jewelry Vacuum Pressure Casting Machine – Hasung Detail:

Features

1. Operation method: One-key operation to complete the entire process, POKA YOKE foolproof system.

2. Control system: Mitsubishi PLC+Human-machine interface intelligent control system (optional).

3. Using German high-frequency heating technology, automatic frequency tracking and multiple protection technologies, it can be melted in a short time, energy saving, and high work efficiency.

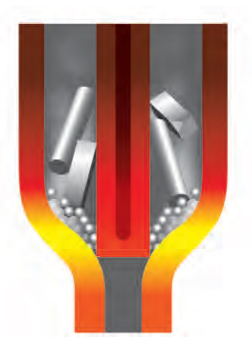

4. The closed type/channel type + vacuum/inert gas protection melting chamber can prevent the oxidation of molten raw materials and the mixing of impurities. This equipment is suitable for the casting of high-purity metal materials or elemental metals that are easily oxidized.

5. Adopt closed/channel type + vacuum/inert gas to protect the melting chamber, melting and cooling are performed at the same time, the time is halved and the production efficiency is increased.

6. Melting in an inert gas environment, the oxidation loss of the carbon mold is almost negligible.

7. With the electromagnetic stirring function under the protection of inert gas, there is no segregation in color.

8. It adopts Mistake Proofing (anti-fool) automatic control system, which is easier to use.

9. Using PID temperature control system, the temperature is more accurate (±1°C).

10. HS-VC gold and silver casting forming equipment/full-automatic production line is independently developed and manufactured with advanced technical level products for the smelting and casting of gold, silver, copper and other alloys.

11. This equipment uses Mitsubishi PLC program control system, SMC pneumatic and Panasonic servo motor drive and other domestic and foreign brand components.

12. Melting, electromagnetic stirring, and refrigeration in a closed/channel + vacuum/inert gas protection melting room, so that the product has the characteristics of no oxidation, low loss, no porosity, no segregation in color, and beautiful appearance.

Why Do You Choose Hasung Vacuum Pressure Casting Machine?

Hasung Vacuum Casting Machines compare to other companies

1. Energy saving. With low power consumption of 5KW 220V single phase.

2. Good melting speed. Melting speed is within 2 minutes which is as fast as others’ machines of 15KW 380V.

3. 1kg or 2kg capacity could be equipped with 220V single phase which is suitable for the clients who don’t have 380V 3 phases electricity. Main power 5KW, casting quantity in 18 kt up to 2,000 g. 380V 8KW is optional which melting speed is faster.

4. Hasung original parts are from well-known domestic Japan and German brands.

Technical Parameters

| Model No. | HS-VC1 | HS-VC2 | HS-VC4 |

| Voltage | 220V, 50/60Hz single phase | 220V /380V, 50/60Hz, 3 phases | 380V, 50/60Hz, 3 phases |

| Power Supply | 5KW | 5KW/8KW | 8KW |

| Max Temp | 1500°C | ||

| Melting Time | 2-3 min. | 3-5 min. | 3-5 min. |

| Protective Gas | Argon / Nitrogen | ||

| Temp Accuracy | ±1°C | ||

| Capacity (Gold) | 1kg | 2kg | 4kg |

| Casting pressure | 0.1-0.3Mpa (Adjustable) | ||

| Vacuum Pump | High quality vacuum pump | ||

| Application | Gold, K gold, silver, copper and other alloys | ||

| Operation method | One-key operation to complete the entire process, POKA YOKE foolproof system | ||

| Cooling type | Water chiller(sold separately) or Running water | ||

| Dimensions | 680*680*1230mm | ||

| Weight | approx. 120kg | approx. 120kg | approx. 130kg |

Product Display

Product detail pictures:

Related Product Guide:

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for 2022 High quality Gold Making - VC Series Jewelry Vacuum Pressure Casting Machine – Hasung , The product will supply to all over the world, such as: Thailand, San Diego, Latvia, If any product meed your demand, remember to feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality merchandise, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.